Solar cell spring testing probe

A technology of solar cells and test probes, which is applied in the monitoring of photovoltaic power generation, electrical components, photovoltaic systems, etc., can solve the problems of current and voltage loss, interference test results, probe heads and probe sleeves stuck, etc. The effect of reducing the number of connected components, reducing the shading area, and avoiding sliding wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

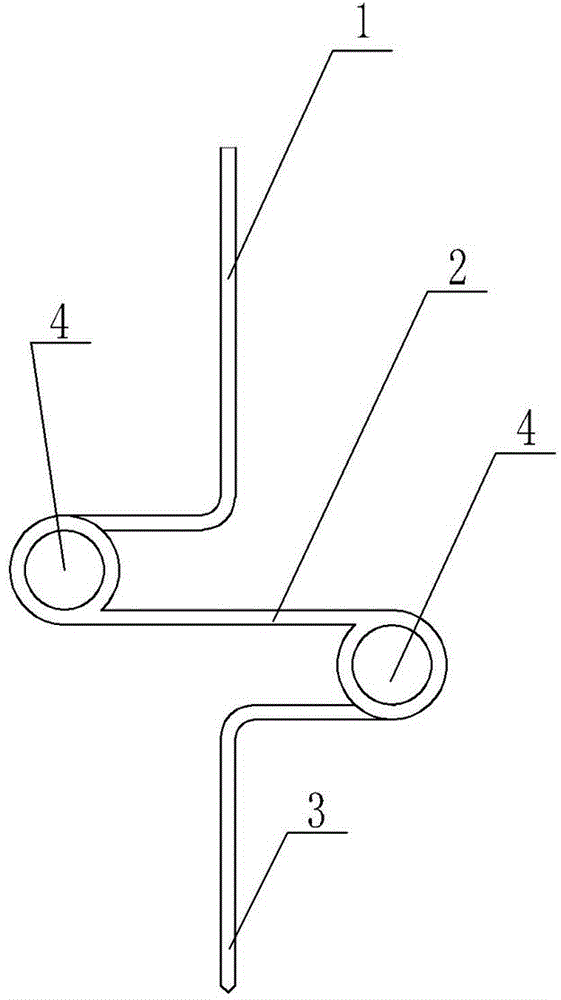

Embodiment 1

[0022] The solar cell sheet spring test probe of the present invention is provided with a linear connector 1, a spring part 2 and a contact 3 sequentially from top to bottom, and the linear connector 1, spring part 2 and contact 3 are integrated Structure; the spring part 2 is a quasi-S-shaped spring, and the contact 3 is linear; a buffer ring 4 is respectively provided inside the two bent ends of the quasi-S-shaped spring. The linear connector 1, the spring part 2 and the contact 3 of the probe described in this embodiment are all cylindrical with the same diameter, and the diameter thereof is 0.5 mm. The probes described in this embodiment are made of phosphor bronze probes or aluminum cupronickel wires. The phosphor bronze probes or aluminum cupronickel wire probes have good compression resistance and prevent fatigue points of materials. The S-shaped spring of the present invention replaces the original spring structure, and plays a good buffering role between the connector...

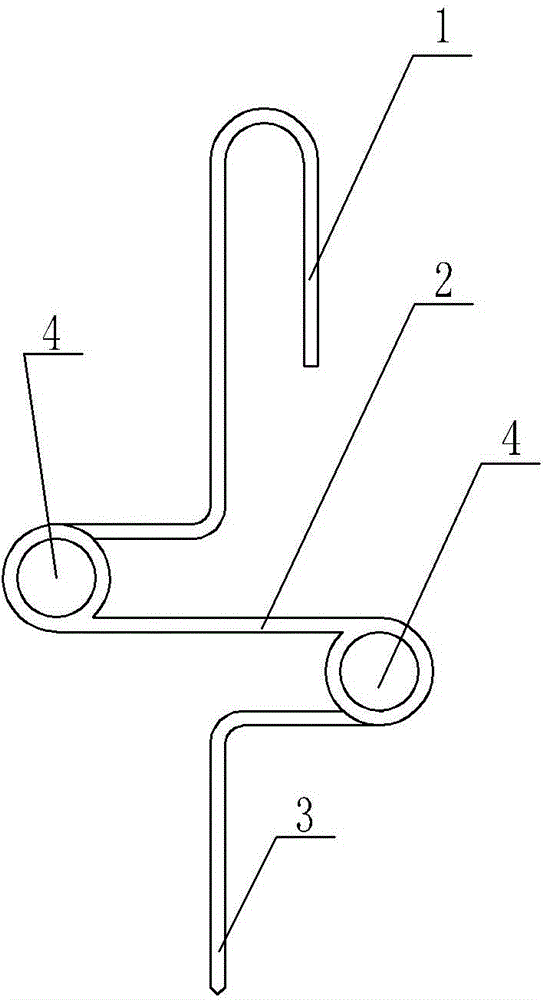

Embodiment 2

[0025] This embodiment is basically the same as Embodiment 1, except that the connector 1 described in this embodiment is a connector 1 in the shape of "?", and the probe can be hooked on the test device by using the connector 1 of this shape. , and fixed, the hook structure described in this embodiment has better convenience in installation and fixation than the linear structure described in embodiment 1.

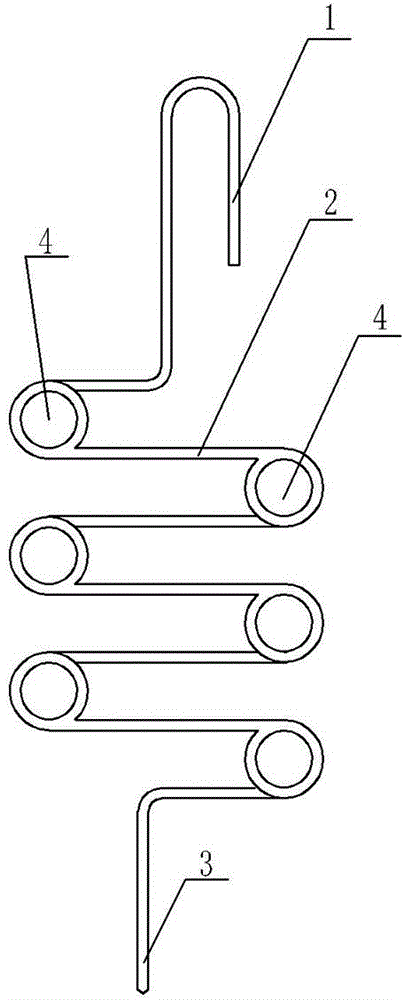

Embodiment 3

[0027] This embodiment is basically the same as Embodiment 1 or 2, the difference is that there are multiple sets of spring parts 2 in this embodiment, and multiple sets of spring parts 2 have better cushioning performance, stronger elasticity, and can protect solar energy more favorably. battery to prevent it from being crushed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com