A high-purity ammonia production device

A production device, high-purity ammonia technology, applied in the direction of ammonia preparation/separation, etc., can solve the problems of high cost, difficult ammonia gas purification and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

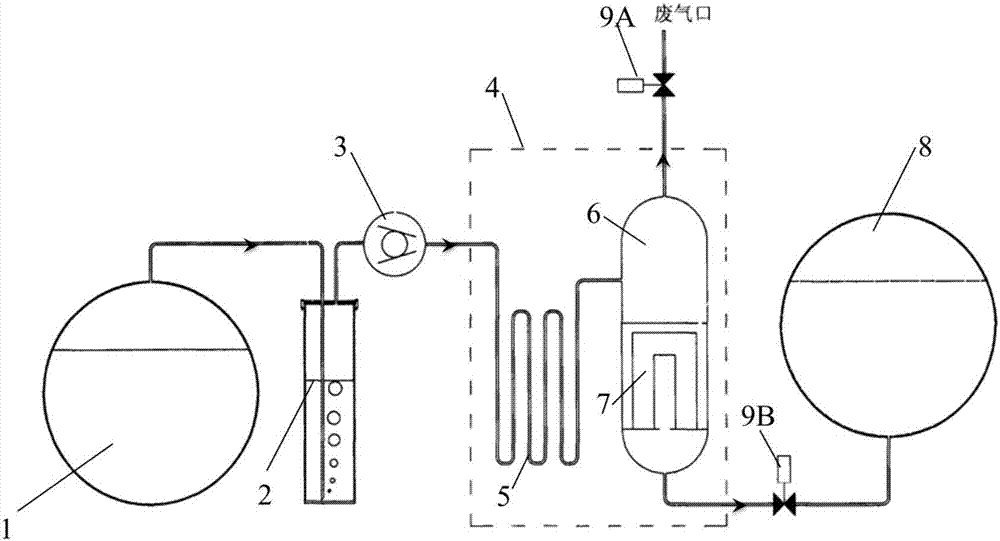

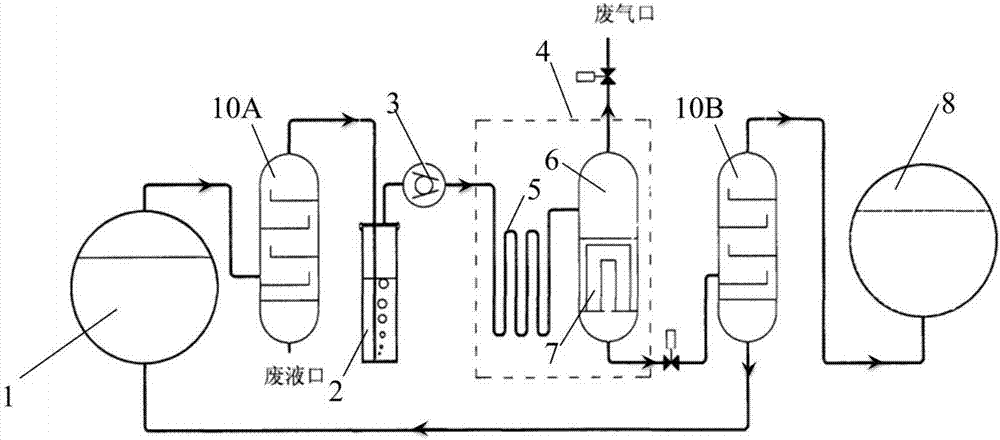

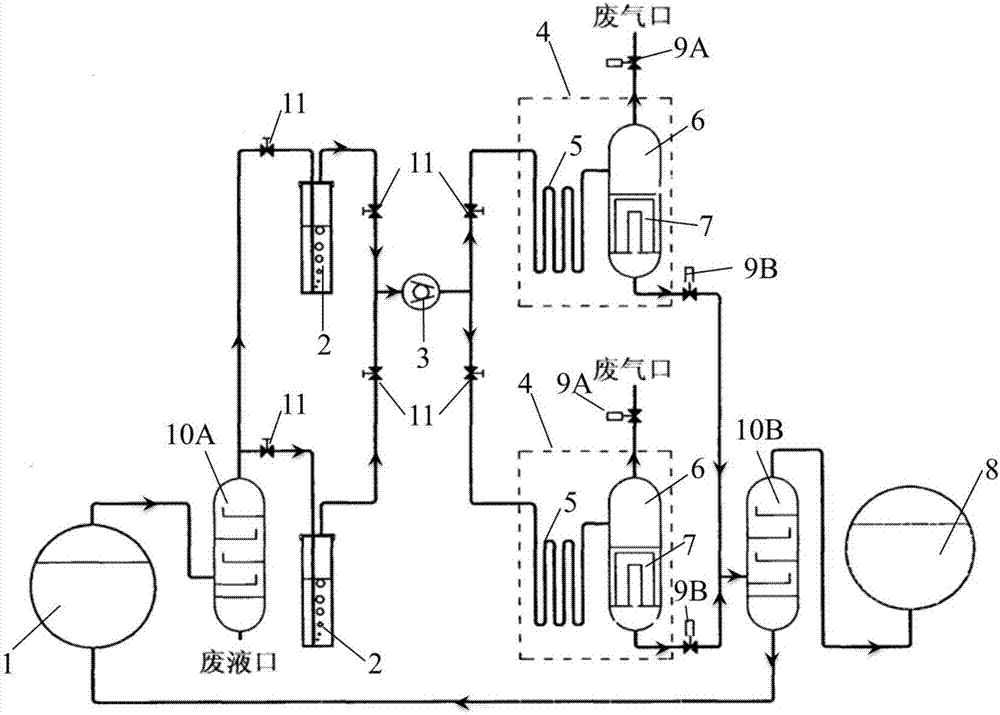

[0025] figure 1 It is a schematic diagram of the first embodiment of the present invention. The device is composed of the following components connected in sequence with stainless steel pipes: ammonia raw material tank 1, potassium-sodium alloy tank 2, diaphragm compression pump 3, condenser 5, gas-liquid separation tank 6, and ammonia product tank 8. The arrows on the pipes in the figure represent the flow direction of gas or liquid in the pipes. Put activated carbon filter 7 in gas-liquid separation tank 6. Condenser 5 and gas-liquid separation tank 6 and gac filter 7 are placed in freezer 4.

[0026] Potassium-sodium alloy tank 2 is filled with potassium-sodium alloy—it is produced by melting together high-purity metal potassium and sodium in a ratio of 1:1. Its melting point is ~25°C, and it is liquid at room temperature. The potassium-sodium alloy is placed in a stainless steel container to form a potassium-sodium alloy tank 2 . The shell of potassium-sodium alloy ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com