Preparation method of silicon-steel grade magnesium oxide

A magnesia, silicon steel grade technology, applied in magnesia and other directions, can solve the problems of magnesia multiple quality defects, product quality fluctuations, low reaction temperature, etc., achieve uniform particle size distribution, improve automation level, low impurity content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

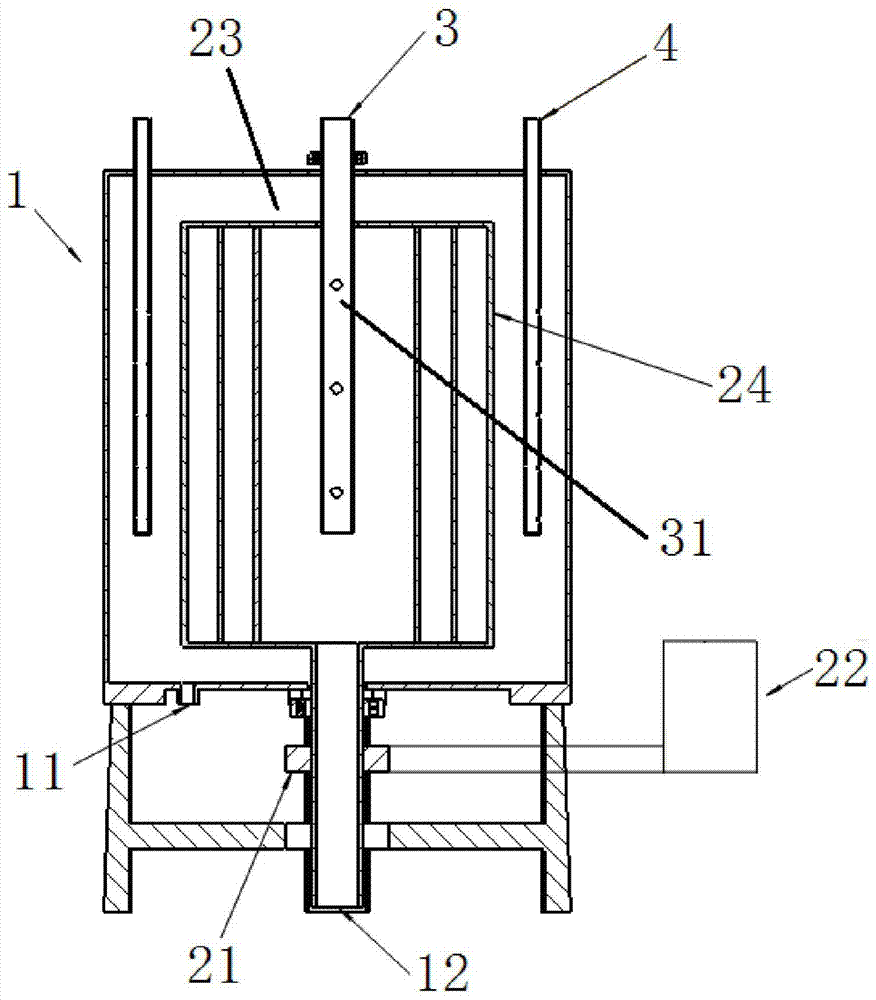

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below.

[0029] A method for preparing silicon steel grade magnesium oxide includes the following steps:

[0030] 1) Ingredients and impurity removal: Put the crude magnesium oxide powder into a container, add pure water for mixing, and wash and remove impurities from the prepared slurry. The container can use equipment such as ultrasonic or dispersion mill. In order to achieve the effect of uniformly dispersing the powder in water, a high-speed mixer is preferably used.

[0031] 2) Rotating bed high temperature treatment: the slurry obtained in step 1) is pumped into a rotating bed reactor for reaction to obtain a slurry. The rotating bed reactor uses superheated steam heating mode to work. The temperature of steam fed into the rotating reactor is between 100°C and 140°C, the temperature of the output ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com