Clamping-groove multistage series-capacitor deionizer

A series capacitor and card slot technology, applied in the field of wastewater treatment, can solve the problems of uneven water distribution, high maintenance cost, and easy short circuit of the pole plate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

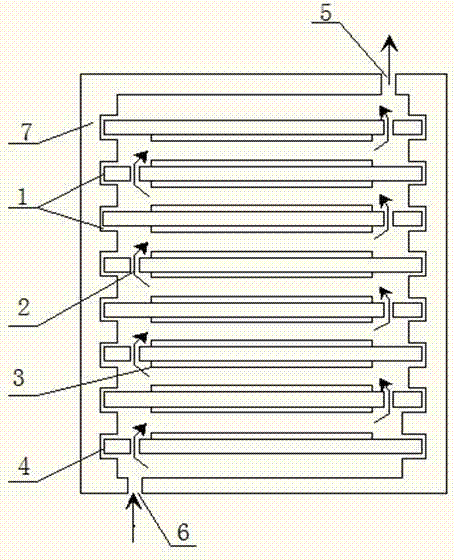

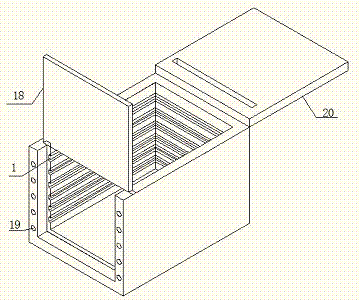

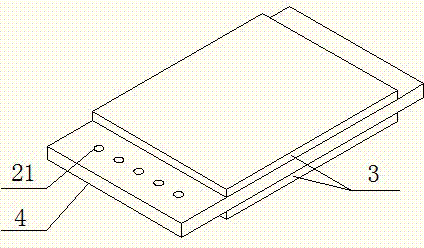

[0023]The technical process of the embodiment: 8 raw water tanks are supplied with water by 10 water pumps and enter the security filter 11 of the next processing unit. The security filter can remove some relatively large particles of impurities in the raw water, and plays a very good role in preventing the clogging and short circuit of the electro-adsorption unit. The water filtered by the security filter enters the 6-slot multi-stage series capacitive deionization device, and the multi-stage electroadsorption deionization is completed in the electro-adsorption unit, and the water ion removal of the water produced by the 8-product water tank reaches 80%. The embodiment sets three valves. 9 valves are maintenance valves used for maintenance when the water pump fails; 16 valves are water production tank valves, which are open when the device is in the electro-adsorption working state and closed during desorption; 17 valves are desorption water tank valves The valve is open only...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com