Sewage nitrogen and phosphorus removal method and device

A technology for denitrification and phosphorus removal and sewage, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. Low recovery rate and other problems, to achieve the effects of stable sewage treatment quality, long service life, convenient and simple material acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

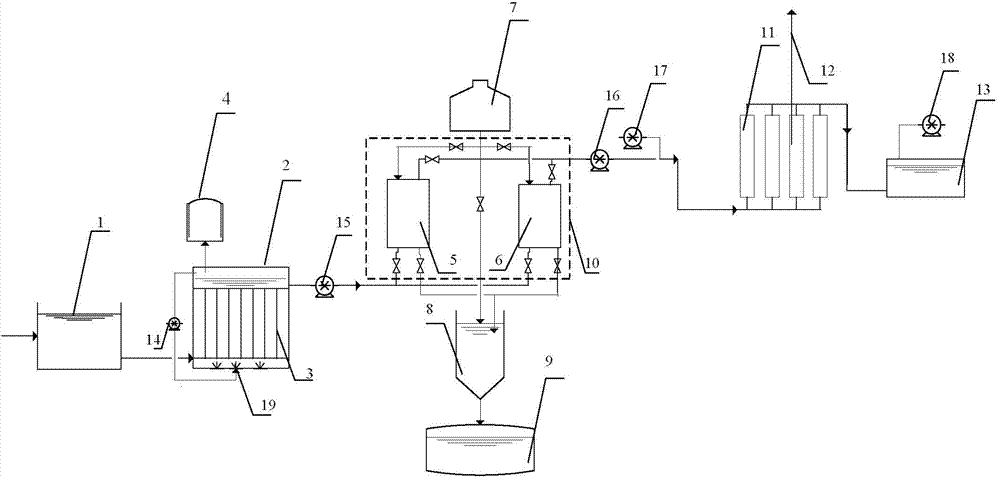

[0035] Such as figure 1 As shown, a sewage denitrification and phosphorus removal device is mainly composed of a water inlet tank 1, anaerobic membrane bioreactor 2, adsorption tank 10 and gas separation membrane device 11 connected in sequence, and the adsorption tank 10 and gas separation membrane device 11 The inlet end is connected, and the outlet end of the gas separation membrane device 11 is connected to the ammonia nitrogen absorption pool 13 and the water outlet 12 respectively.

[0036]The present invention adopts an anaerobic membrane bioreactor treatment system, which includes a water inlet pool 1, an anaerobic membrane bioreactor 2, a gas collection device 4, a membrane surface scouring device 19, and a vacuum diaphragm pump 14. A mechanical agitator is provided in the water inlet pool 1, and the water inlet pool 1 and the anaerobic membrane bioreactor 2 are connected by short pipes. A gas collection device 4 is arranged above the anaerobic membrane bioreactor 2,...

Embodiment 2

[0044] The method for denitrification and dephosphorization of sewage of the present invention comprises the following steps:

[0045] Step 1. Anaerobic hydrolysis: the sewage entering the anaerobic membrane bioreactor 2 from the inlet pool 1 undergoes anaerobic hydrolysis fermentation reaction in the anaerobic membrane bioreactor 2, and this reaction degrades a large amount of COD in the sewage, while the sewage in the sewage The organic nitrogen and organic phosphorus in the anaerobic membrane bioreactor 2 are converted into ammonia nitrogen and phosphate, and flow out of the anaerobic membrane bioreactor 2 with water under the action of the first suction pump 15 .

[0046] Step 2. Phosphorus removal and recovery by adsorption: the sewage that enters the first adsorption pool 5 from the anaerobic membrane bioreactor 2 undergoes a phosphorus adsorption process in the first adsorption pool 5, and the adsorbed sewage is acted on by the second suction pump 16 Enter the phosphoru...

Embodiment 3

[0050] In a simulation test of wastewater from a poultry breeding factory in Lishui District, Nanjing, the invention was used to treat poultry breeding wastewater.

[0051] The influent COD concentration of the anaerobic membrane bioreactor is 3548mg / L, the total nitrogen (TN) concentration is 522mg / L, and the ammonia nitrogen (NH 3 -N) concentration is 510mg / L, total phosphorus (TP) concentration is 25mg / L, and the inlet water temperature is 16-20°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com