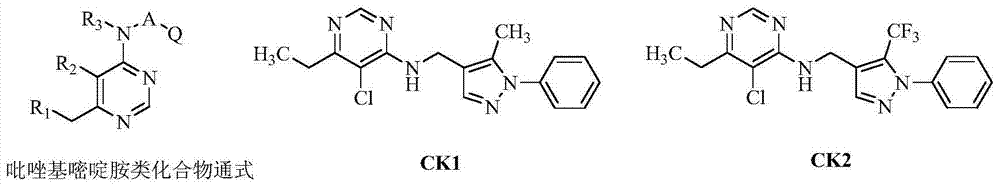

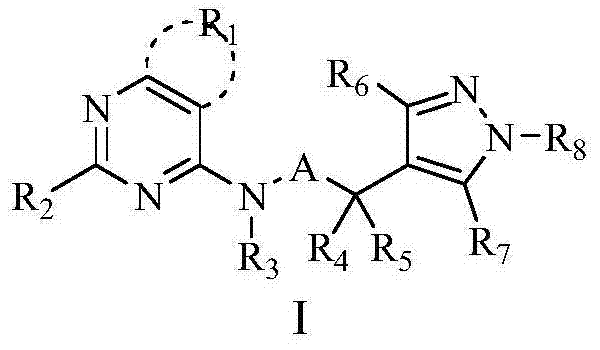

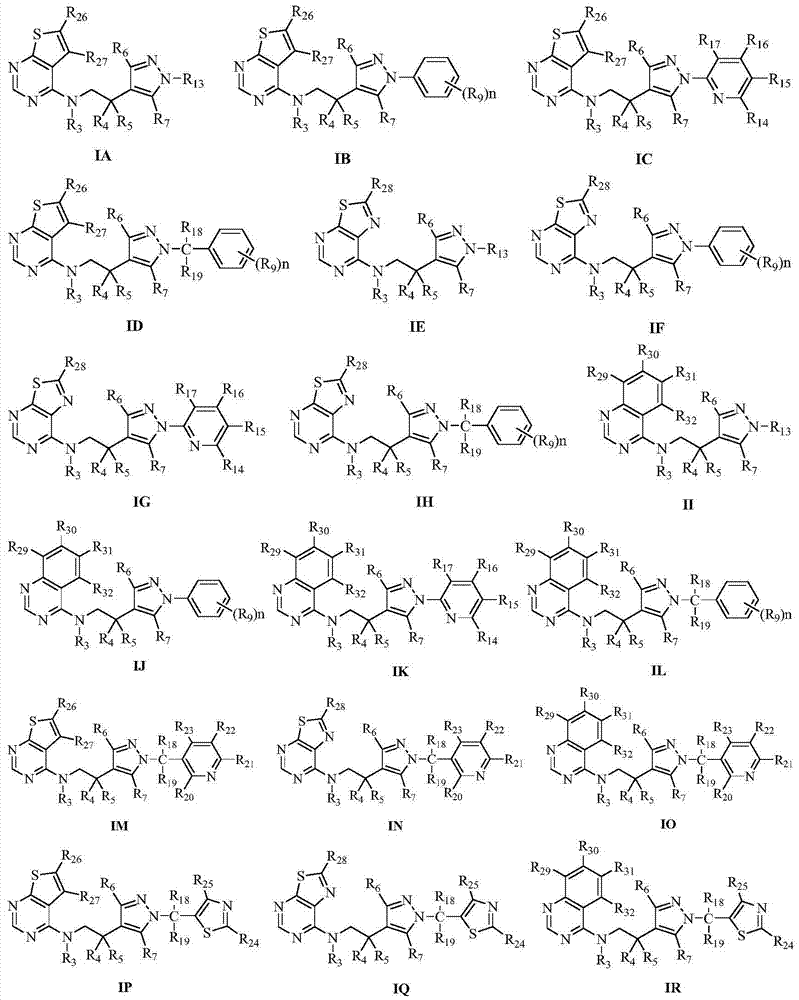

Pyrazolyl pyrilamine compound and use thereof

A pyrazolyl pyrimidine amine compound technology, applied in the field of pyrazolyl pyrimidine amine compounds, can solve the problems that the structure of pyrazolyl pyrimidine amine compounds has not been reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0321] Example 1: Preparation of 4,5-dichlorothieno[2,3-d]pyrimidine

[0322]

[0323] Take 2-amino-3-cyano-4-oxy-4,5-dihydrothiophene and 250ml phosphorus oxychloride (POCl 3 ) In the reaction flask, slowly add 38ml of dimethylformamide (DMF) dropwise at room temperature, and the addition is completed in about 30 minutes. React at room temperature for 1 hour, and then increase to 75°C for 3 hours. After cooling to room temperature, the reaction solution was poured into crushed ice and filtered to obtain 89.1 g of dark gray solid with a yield of 86.9% and a melting point of 160-161°C.

Embodiment 2

[0324] Example 2: Intermediate 2-(1-(2,4-Dichlorophenyl)-1H-pyrazol-4-yl)ethylamine

[0325] 1) Preparation of 1-(2,4-dichlorophenyl)-1H-pyrazole

[0326]

[0327] Take 21.35g (0.1mol) 2,4-dichlorophenylhydrazine hydrochloride and 16.4g (0.1mol) 1,1,3,3-tetramethoxypropane in a 250ml three-necked flask, and 100ml of 95% ethanol aqueous solution as The solvent is heated to reflux for 3-5 hours. After the reaction was monitored by TLC, most of the ethanol was evaporated under reduced pressure, sodium carbonate aqueous solution was added to the remaining liquid, the aqueous phase was extracted with (3×100ml) ethyl acetate, the organic phases were combined, dried with anhydrous magnesium sulfate, filtered and desolventized . The residue was separated by column chromatography (eluent was ethyl acetate and petroleum ether, the volume ratio was 1:10) to obtain 18.06 g of yellow solid, with a yield of 84.8%.

[0328] 2) Preparation of 1-(2,4-dichlorophenyl)-1H-pyrazole-4-carbaldehyde

[03...

Embodiment 3

[0343] Example 3: Preparation of compound 66

[0344]

[0345] Take 2.05g (0.01mol) 4,5-dichlorothieno[2,3-d]pyrimidine and 2.56g (0.01mol) 2-(1-(2,4-dichlorophenyl)-1H-pyrazole -4-yl) ethylamine was added to 50ml of ethanol, 2.02g (0.02mol) of triethylamine was added with stirring at room temperature, heated to reflux, reacted for 5 hours, TLC monitored the reaction, the solvent was evaporated under reduced pressure, and (3× 50ml) ethyl acetate extraction, the organic phase was washed with 50ml saturated brine, and the solvent was removed under reduced pressure, and the residue was column chromatographed (eluent: ethyl acetate and petroleum ether (boiling range 60-90℃), volume ratio 1 :3) 3.56 g of white solid was obtained, the yield was 83.8%, and the melting point was 131.6°C.

[0346] 1 H-NMR (300MHz, internal standard TMS, solvent CDCl 3 )δ(ppm): 2.97(2H,t),3.81-3.98(2H,q),6.65(1H,s),6.72(1H,t),7.32-7.48(2H,m),7.52(1H,t) ), 7.60 (1H, d), 7.64 (1H, s), 8.57 (1H, s).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com