In-situ leaching uranium mining method by using mixing organic acidity as leaching agent

A technology for uranium mining by mixing organic acids and in-situ leaching, which is applied in the field of uranium mining by in-situ leaching, and can solve the problems of low leaching efficiency, abnormal mining of uranium deposits, and low concentration of uranium in the leach solution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

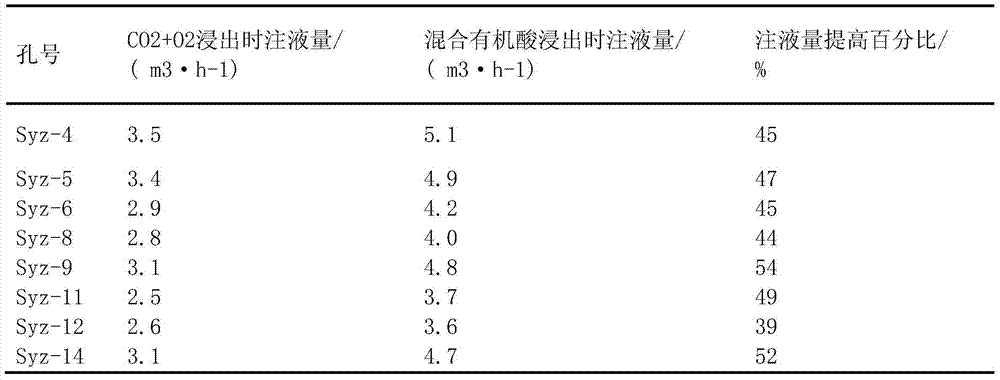

[0024] The test ore body is located on the N8 exploration line of the Nalingou uranium deposit, with an average thickness of 4.40m, an average grade of 0.0709%, and an average uranium content of 6.38kg / m2 2 , with an average buried depth of 400m. After analysis and testing, the carbonate content of the ore is expressed as CO 2 It is calculated as 0.297% to 11.36%, with an average content of 3.41%; the maximum content of organic matter reaches 10.0%, with an average content of 3.26%.

[0025] Use effect of the present invention:

[0026] The test block adopts the leaching process of oxalic acid plus citric acid as the leaching agent, and the specific steps are as follows:

[0027] Step 1, groundwater circulation: first pump out the groundwater of the ore-bearing layer from the pumping hole, then inject it into the ore-bearing layer from the liquid injection hole, and dredge the ore layer through the groundwater circulation, and the cycle lasts for 20 days;

[0028] Step 2, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com