Application of bright yellow disperse dye mixture

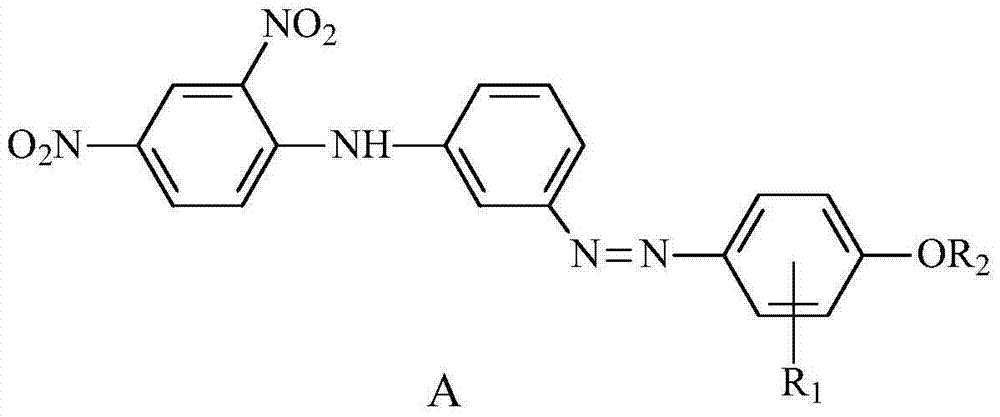

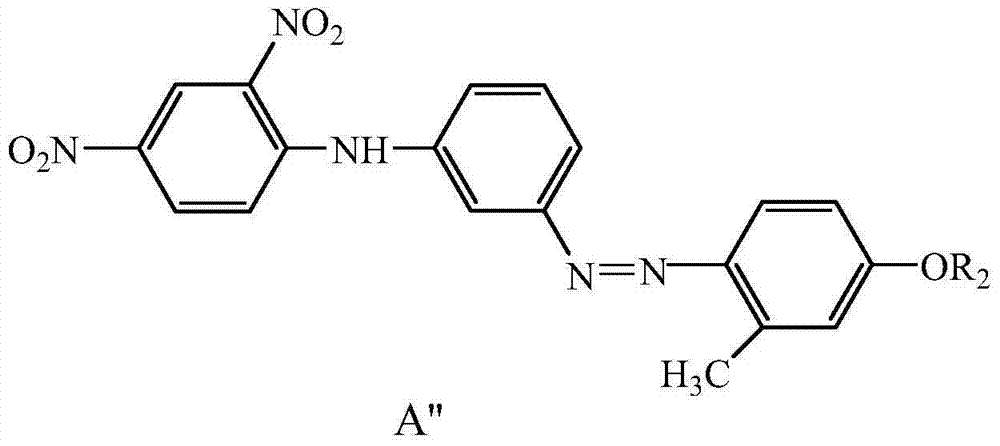

A technology of disperse dyes and mixtures, applied in azo dyes, organic dyes, monoazo dyes, etc., can solve the problems of poor alkali resistance, poor oxidation resistance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

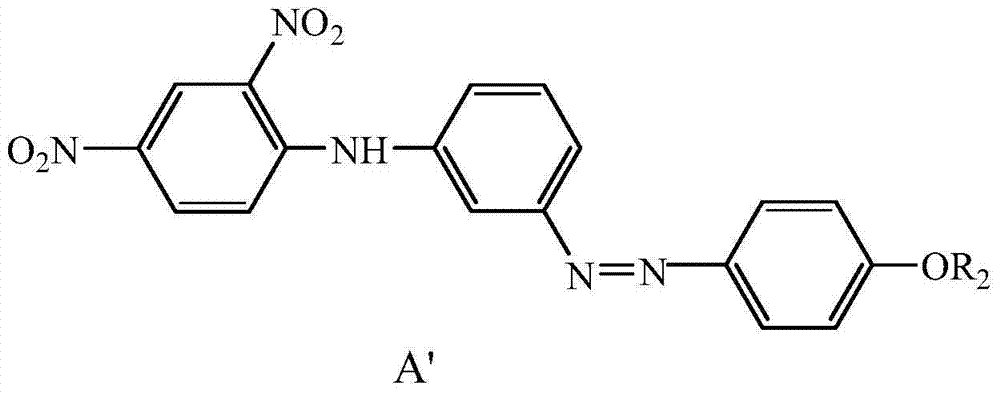

[0122] Preparation of Compound A1: (1) Add 150 g of water and 13.7 g of N-(2,4-dinitro)phenyl-1,3-diaminobenzene into a 250 mL three-neck flask, stir evenly at room temperature for half an hour, then add mass The percentage concentration is 20 grams of hydrochloric acid of 36%, continue to stir for 1.5 hours, add ice and cool to 0-5 ℃, dropwise add 18.6 grams of sodium nitrite solution with a mass fraction of 20%, then continue to react at 0-5 ℃ for 3 hours, Add 0.5 g of sulfamic acid, and test colorless with starch potassium iodide test paper to obtain diazonium salt to be coupled.

[0123] (2) Add 200 grams of water, 7 grams of sodium hydroxide with a mass fraction of 30%, 8.7 grams of sodium carbonate, and 4.8 grams of phenol into a 1000mL beaker. After stirring for half an hour, keep at 0-10°C and add step (1) The obtained diazonium salt was reacted for 3 hours while keeping the pH value at 8-9, heated to 65-70° C. for 2 hours, and filtered to obtain 18 grams of intermedia...

Embodiment 1

[0134] 10 grams of former dyes shown in formula A1, 20 grams of former dyes shown in formula B4, 20 grams of former dyes shown in formula C3, dispersant MF60 grams, sodium lignosulfonate 15 grams, water 153 grams together sand Disperse in a mill, and then spray dry to obtain the light yellow dye mixture of the present invention.

Embodiment 2~30

[0136] According to the preparation method of Example 1, the compounds represented by formulas A, B, and C were ground, dispersed, and spray-dried according to the data shown in Table 1 below.

[0137] Table 1

[0138]

[0139]

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com