A method for improving selectivity and recovery in the flotation of nickel sulphide ores that contain pyrhotite by exploiting the synergy of multiple depressants

A synergy and inhibitor technology, applied in flotation, solid separation and other directions, can solve the problems of lack and the selectivity has not been improved, and achieve the effect of promoting synergy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

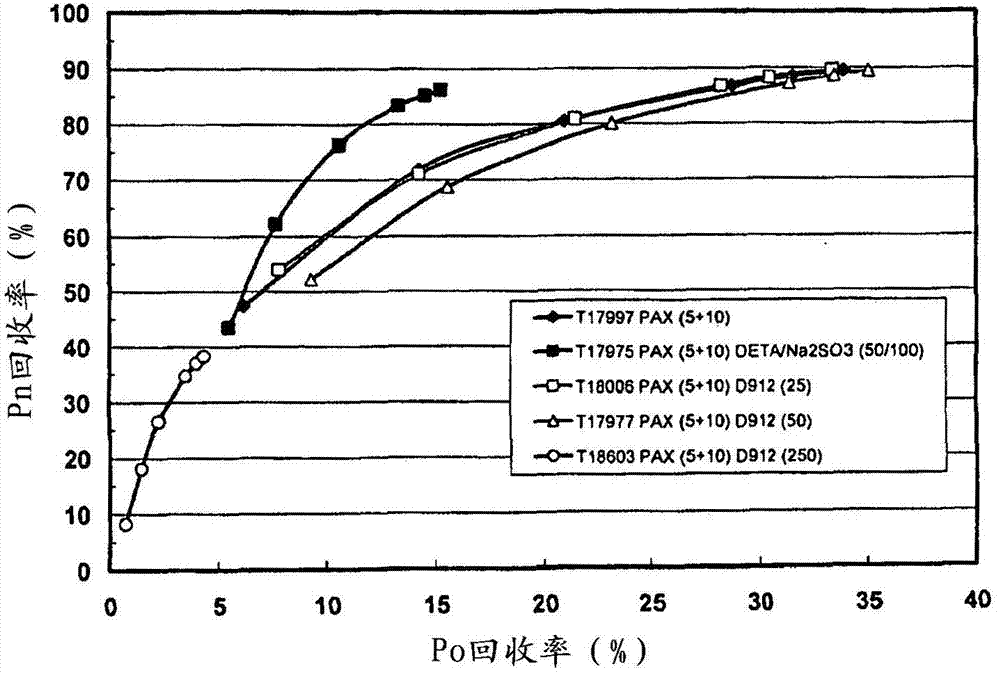

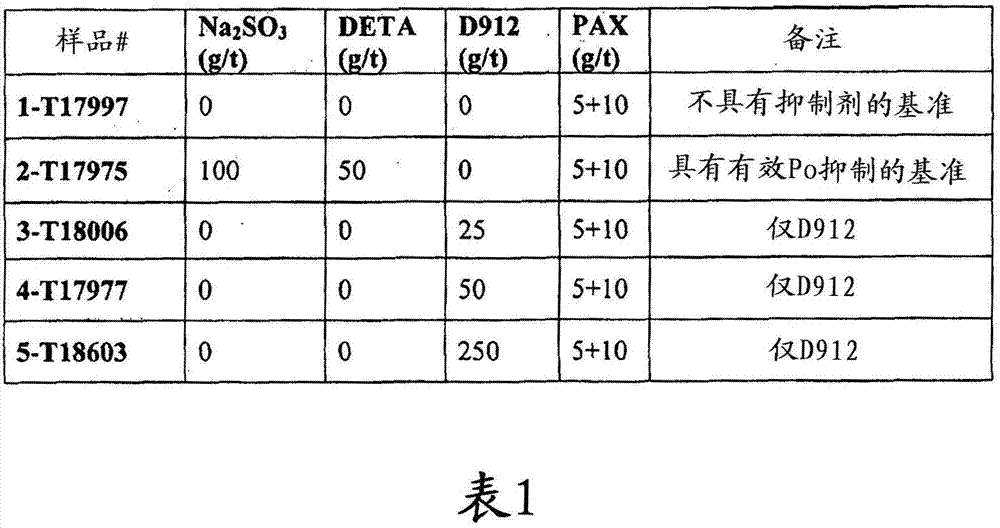

[0065] Inefficient pyrrhotite suppression using only D-912

[0066] figure 1 Nickel-copper ore (containing about 1.5% Ni (3.7% pentlandite), 1.5% Cu (4.3% chalcopyrite) and 21% Fe (19.7% pyrrhotite) and 72.3% rock (other silicates)) in rougher flotation of pentlandite and the results of the cumulative recovery of pyrrhotite. In this test, 1 kg of ore was ground in a rod mill to a P80-106 μm with the addition of 5 g / t collector (PAX – potassium amyl xanthate) and 400 g / t lime. An incremental rougher test was carried out at pH 9.5 using lime as a modifier. There was a 2 minute conditioning with 15 ppm frother (F160-13) in the process water after addition of inhibitor and collector separately. A 2.2L Denver flotation cell with a 1200rpm rotating shaft was used and 3L / min of air was applied in the flotation. Concentrates were collected after 0.5, 1, 2, 5, 8 and 12 minutes. The chemical additions to the rougher are summarized in Table 1.

[0067] Trials using only collector ...

Embodiment 2

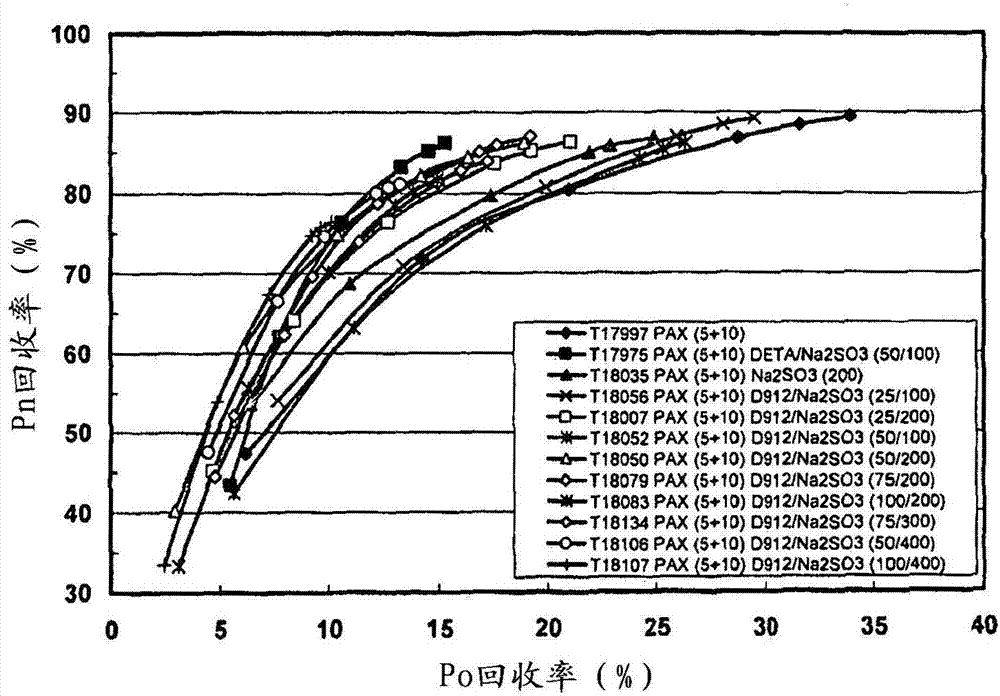

[0070] For an ore raw material, D-912 and Na 2 SO 3 Effective pyrrhotite inhibition of

[0071] figure 2 Results are presented for the cumulative recoveries of pentlandite and pyrrhotite in rougher flotation of the same nickel-copper ore used in Example 1, where Na 2 SO 3 Add D-912 to the rougher. The ore was ground in the same manner as Example 1, including adding 5g / t collector (PAX) and adding 400g / t lime. When Na 2 SO 3 Pyrrhotite inhibition was observed at doses ≥ 200 g / t. In Table 2 the chemical additions in the rougher flotation are summarized.

[0072] Trials using only collector (PAX) showed no pyrrhotite inhibition. Using DETA / Na 2 SO 3 The tests represent acceptable pyrrhotite inhibition and bonanza metal recovery.

[0073] Proved to use 200g / t Na 2 SO 3 Doses of , by themselves, had some effect on pyrrhotite inhibition, but the results were not as good as with the benchmark chemicals DETA and Na 2 SO 3 Get the ones that are so good. Using D-912 an...

Embodiment 3

[0076] For intermediate streams use D-912 and Na 2 S0 3 lower recovery rate

[0077] Figure 3A with 3B Respectively presents a concentration of an intermediate stream containing 7.6% Cu (21.9% chalcopyrite), 6.4% Ni (17.3% pentlandite), 37% Fe (39.8% pyrrhotite) and 21% rock The results of the selectivity of pentlandite / pyrhotite and chalcopyrite / pyrhotite accumulated in machine flotation, where the Na 2 SO 3 Added with D-912 to select machine. This study involved rougher and concentrator flotation trials with inhibitors added to the concentrator section. A total of 10 g / t collector (PAX) was added to the rougher flotation and the rougher concentrate was collected for 6 minutes. In the concentrator section, the rougher concentrate is treated with lime as modifier at pH 9.5. There was a 2 minute conditioning after addition of inhibitor and collector separately, with 15 ppm frother (F160-13) in the process water. A 1.1 L Denver flotation cell with a 900 rpm rotating sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com