Multifunctional plant protection machine with high ground clearance and tracks

A multi-functional, plant protection machine technology, applied in the direction of capturing or killing insects, reducing agricultural gas emissions, applications, etc., can solve the problems of low production efficiency, poor cross-country ability, single function, etc., and achieve high work efficiency and labor efficiency. The effect of low strength and many functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

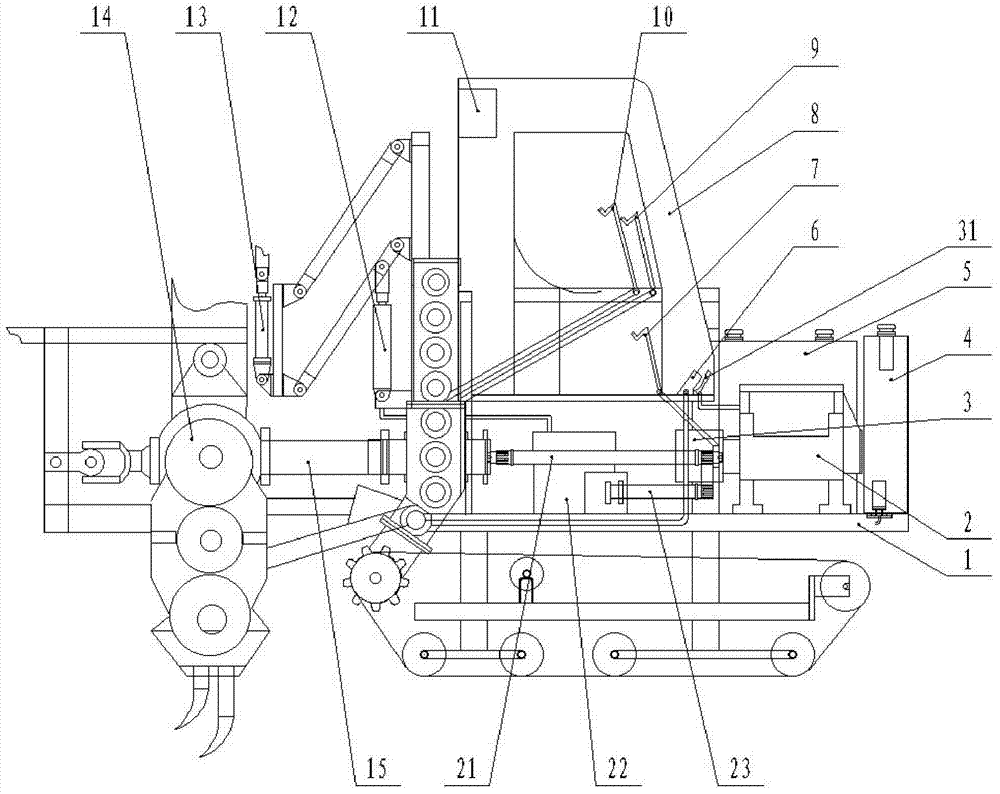

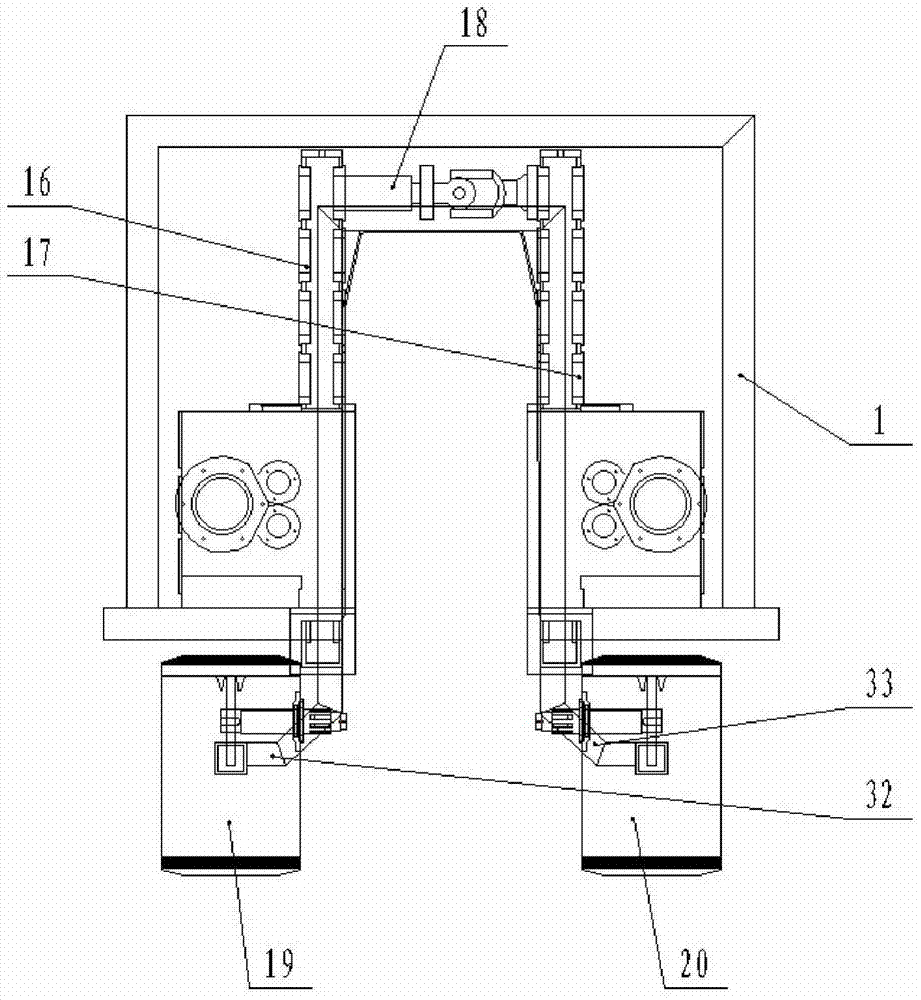

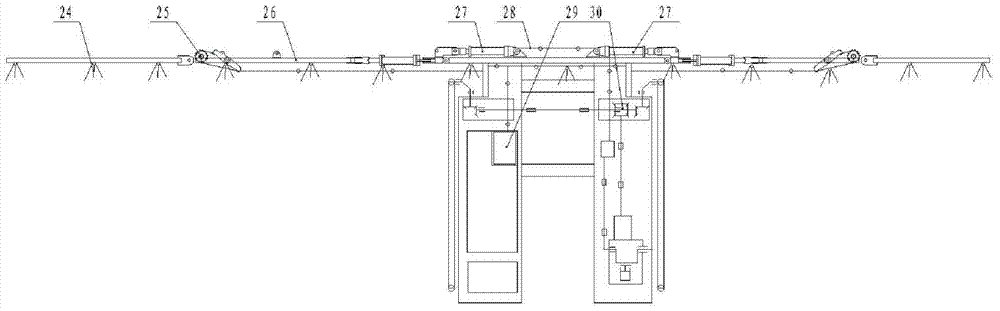

[0034] Such as figure 1 , figure 2 , image 3 As shown, the frame 1 of the present invention is in the shape of a "several" structure, the engine 2 is installed on one side of the front end, the fuel tank 4 and the liquid medicine tank 5 are installed on the other side, the rear end is provided with a left gear box 16 and a right gear box 17, and the bottom A left crawler 19 and a right crawler 20 are provided, the left gearbox 16 and the right gearbox 17 are connected by a cross cardan shaft 18, the left gearbox 16 is connected with the left crawler 19, the right gearbox 17 is connected with the right crawler 20, behind the engine 2 A cab 8 is provided, the gearbox 3 is connected with the right gearbox 17 through the main transmission shaft 21 , and the rear end surface of the frame 1 is provided with a spraying system 13 .

[0035] The present embodiment is a pesticide spraying machine, the vertical height of the central space of the "Ji"-shaped frame 1 reaches 160cm, and...

Embodiment 2

[0037] The difference from Embodiment 1 is that: the left gear box 16 and the right gear box 17 are respectively connected with an auxiliary transmission shaft 15, and the auxiliary transmission shaft 15 is connected with a rotary cultivating, fertilizing and cultivating machine 14.

[0038] This embodiment is a machine for rotary tillage, fertilization, and soil cultivation, or simultaneously implements multifunctional production operations of spraying, rotary tillage, fertilization, and soil cultivation.

Embodiment 3

[0040] The difference with Embodiment 2 is that: the cab 8 is provided with a shift lever 7, a left steering rod 9, a right steering rod 10 and an accelerator pedal 31, and the left steering rod 9 and the right steering rod 10 are connected to the The reversing shift fork 30 on the right gear case 17 is connected, and the reversing shift fork 30 divides the right gear case 17 into upper and lower parts.

[0041] When turning left, the left steering pull rod 9 controls the reversing fork 30 through the traction line to disengage the right gear box 17 top, the left crawler belt 19 loses power and stops advancing, and the right crawler belt 20 continues to move forward, realizing the left turning of the plant protection machine.

[0042] When turning right, the right steering rod 10 controls the reversing fork 30 through the traction line to disengage the lower part of the right gear box 17, so that the right crawler belt 20 loses power and stops moving forward, and the upper part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com