Pseudo-ginseng drying process

A drying process, notoginseng technology, applied in the direction of drying solid materials, drying solid materials without heating, drying, etc., can solve the problems of uneven temperature, high moisture content, poor hygiene indicators, etc., and achieve the reduction of the total bacterial population Obvious, the effect of reducing heavy metal residues and improving hygiene indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

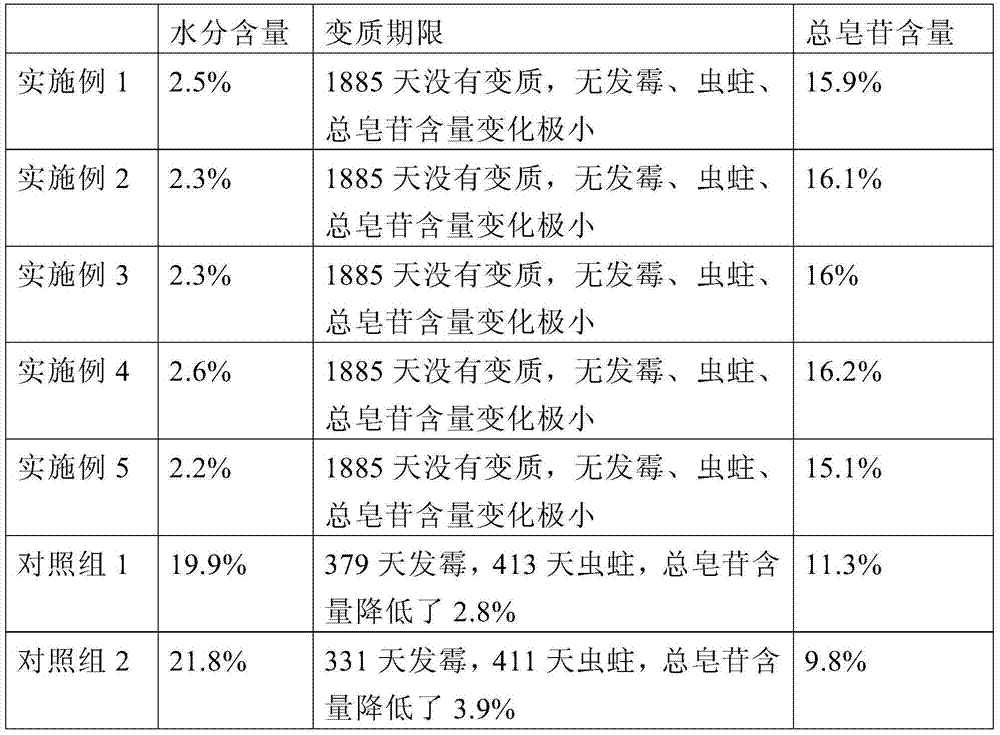

Examples

Embodiment 1

[0032] This embodiment provides a kind of notoginseng drying process, comprising:

[0033] (1) sorting of notoginseng; (2) removal of large roots and fibrous roots; (3) cleaning with high-pressure water gun or brush cleaning equipment; (4) rinsing 3 times; (5) refrigeration (refrigeration temperature is -8 ° C ~ 4 ° C ); (6) quick-freezing (10-15°C cooling rate per minute for quick-freezing temperature to -25°C for 5 hours); (7) sublimation drying (sublimation drying temperature is -28°C to -38°C, absolute pressure is 7 Pa, drying time: 25 hours); (8) analytical drying (the temperature of analytical drying is: -40°C ~ -50°C, the absolute pressure is 8 Pa, drying time: 3.5 hours); (9) finished product.

Embodiment 2

[0035] This embodiment provides a kind of notoginseng drying process, comprising:

[0036] (1) sorting of notoginseng; (2) removal of large roots and fibrous roots; (3) cleaning with high-pressure water gun or brush cleaning equipment; (4) rinsing 3 times; (5) refrigeration (refrigeration temperature is -8°C); ( 6) Quick freezing (quick freezing at a cooling rate of 10-15°C per minute and keeping the temperature at -30°C for 4 hours); (7) Sublimation drying (sublimation drying temperature is -28°C to -38°C, absolute pressure is 3 Pa, drying The time is: 36 hours); (8) analytical drying (the temperature of the analytical drying is: -40°C to -50°C, the absolute pressure is 13 Pa, and the drying time: 5 hours); (9) the finished product.

Embodiment 3

[0038] This embodiment provides a kind of notoginseng drying process, comprising:

[0039] (1) Sanqi sorting; (2) removing large roots and fibrous roots; (3) washing with high-pressure water gun or brush cleaning equipment; (4) rinsing 3 times; (5) refrigeration (refrigeration temperature is -4°C); ( 6) Quick-freezing (10-15°C cooling rate per minute for quick-freezing temperature to -35°C for 3 hours); (7) Sublimation drying (sublimation drying temperature is -28°C to -38°C, absolute pressure is 6 Pa, drying The time is: 30 hours); (8) analytical drying (the temperature of the analytical drying is: -40°C to -50°C, the absolute pressure is 9 Pa, the drying time: 2 hours); (9) the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com