Cu3(BTC)2-modified capillary tube as well as preparation method and application thereof

A capillary, solution technology, applied in the field of chromatography

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Pretreatment of capillary: first use CH 3 Wash the capillary with OH and secondary water for 5-15 minutes, then rinse the capillary with 1.5 mol / L NaOH solution for 10-20 minutes, then seal both ends of the capillary, and place it in an oven at 100°C for 2 hours. After the reaction, the capillary was cleaned successively with 0.5 mol / L HCl, secondary water and acetone, blown dry with nitrogen, and dried in an oven at 120°C for 1.5 h for later use;

[0025] (2) Preparation of γ-glycidyl etheroxypropyltrimethoxysilane-iminodiacetic acid sodium solution: Dissolve 2.12g of iminodiacetic acid sodium in 25mL of secondary water, adjust the pH of the solution with 10mol / L NaOH solution to After 11.0, add γ-glycidyloxypropyl trimethoxysilane in two batches: first slowly add 0.7mL of γ-glycidyloxypropyltrimethoxysilane to the above iminodiacetic acid in an ice-water bath Sodium solution, after mixing, transfer the system to a water bath at 65°C, stir and react for 6 h, then ...

Embodiment 2~6

[0030] The difference from Example 1 is that the steps (4) of Examples 2-6 are repeated 5, 10, 15, 20 and 25 times in sequence.

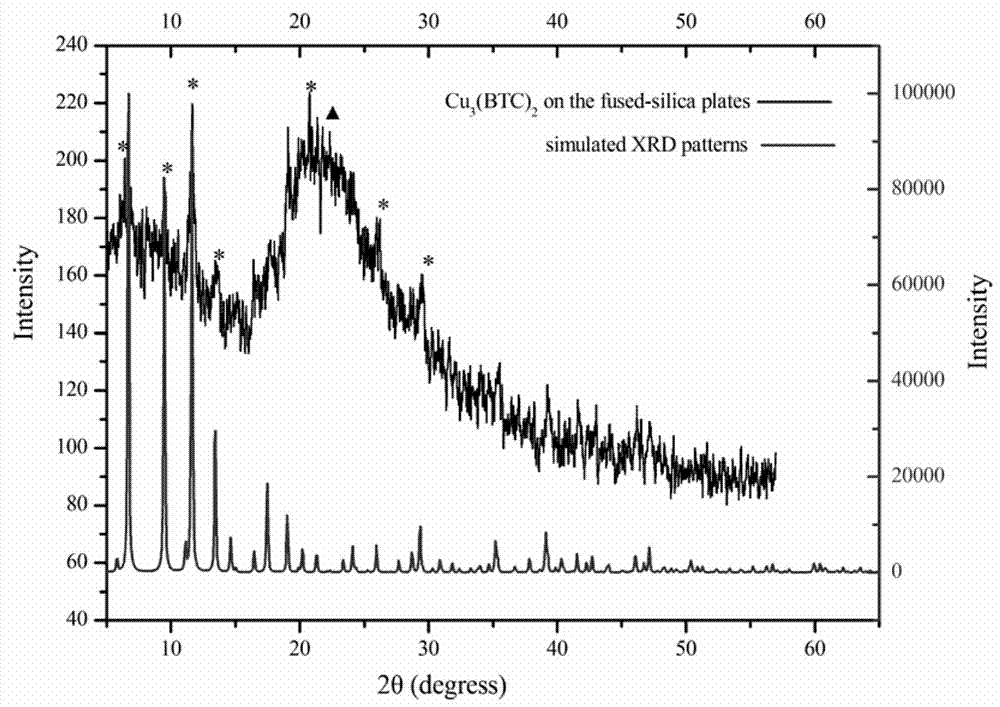

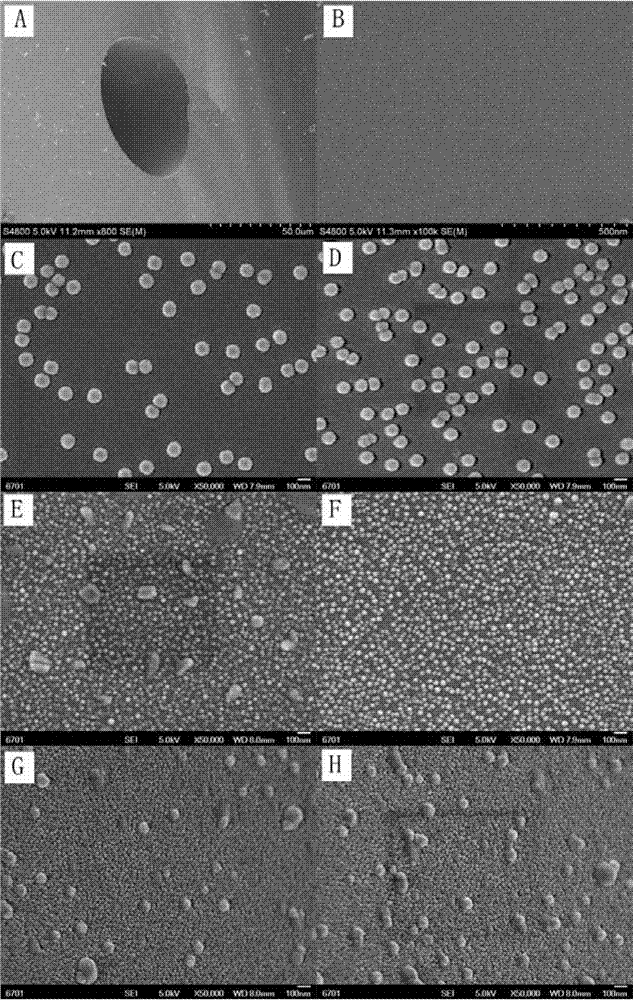

[0031] figure 2 It is the SEM picture of the inner wall of the capillary, wherein, A is a cross-sectional view, B is the inner wall of the bare capillary, and C-H correspond to Examples 1-6 in turn. by such as figure 2 It can be seen that the Cu on the inner wall of the capillary can be controlled by the number of modifications. 3 (BTC) 2 thickness of.

[0032] Table 1 Cu in the capillary of Examples 1-6 2+ Determination of content

[0033]

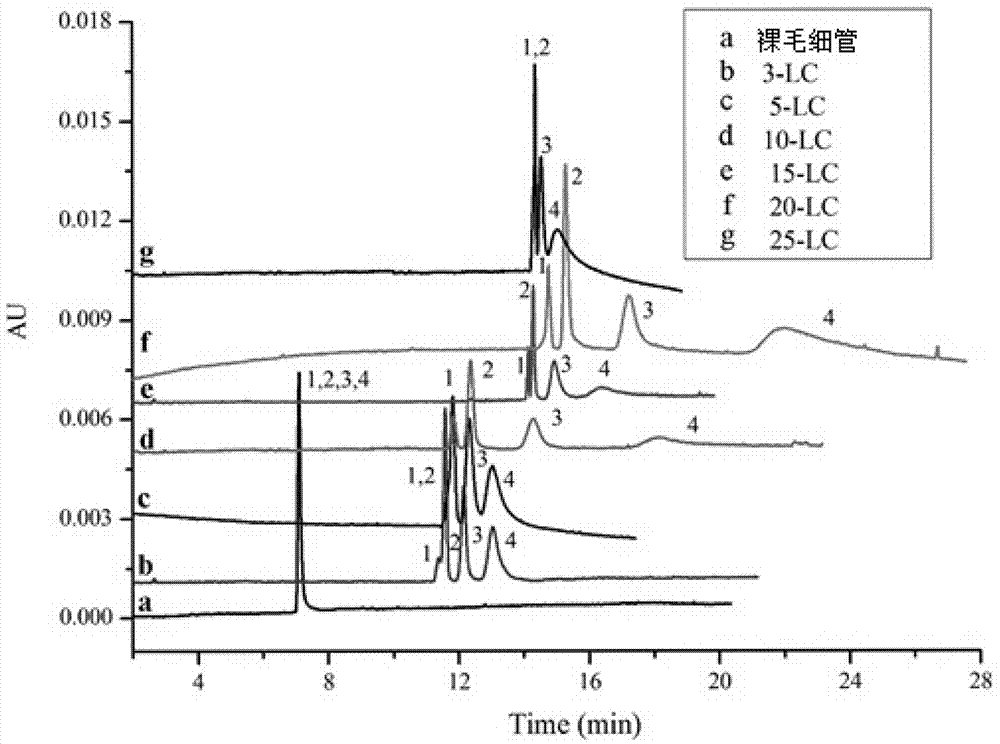

[0034] image 3 Capillary electrochromatographic separation of neutral small molecules by the capillary tubes of Examples 1-6 (corresponding to 3-LC, 5-LC, 10-LC, 15-LC, 20-LC, 25-LC respectively). 1. Benzene; 2. Naphthalene; 3. Acenaphthene; 4. Phenanthrene. Separation voltage: +20 kV. Detection wavelength: 214 nm. Capillary: total length 49.5 cm, effective length 41.0 cm. The sample solution ...

Embodiment 7

[0039] (1) Pretreatment of capillary: first use CH 3 Wash the capillary with OH and secondary water for 5-15 minutes, then rinse the capillary with 0.5 mol / L NaOH solution for 10-20 minutes, then seal both ends of the capillary, and place it in an oven at 100°C for 1.5 hours. After the reaction, the capillary was cleaned successively with 0.5 mol / L HCl, secondary water and acetone, blown dry with nitrogen, and dried in an oven at 120°C for 1.5 h for later use;

[0040] (2) Preparation of GLYMO-IDA solution: Dissolve 2.12g of sodium iminodiacetate in 25mL of secondary water, adjust the pH of the solution to 10.0 with 10mol / L NaOH solution, and then add γ-glycidyl etheroxypropyl in two batches Trimethoxysilane: slowly add 0.7mL γ-glycidyl etheroxypropyl trimethoxysilane to the above sodium iminodiacetate solution in an ice-water bath, and transfer the system to a 60°C water bath after mixing , after stirring and reacting for 6 h, transfer the system to an ice-water bath, then s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com