Preparation method for feather-keratin-modified cadmium sulfide photocatalyst

A technology of feather keratin and photocatalyst, which is applied in the field of preparation of cadmium sulfide photocatalyst, can solve the problems of easy compounding and low photocatalytic activity of CdS

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

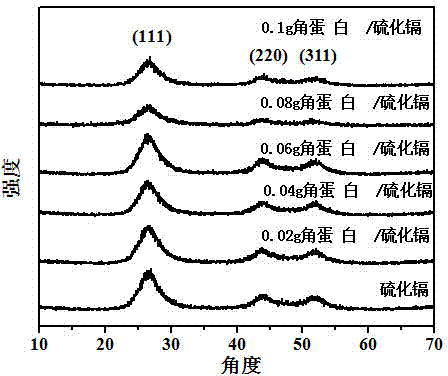

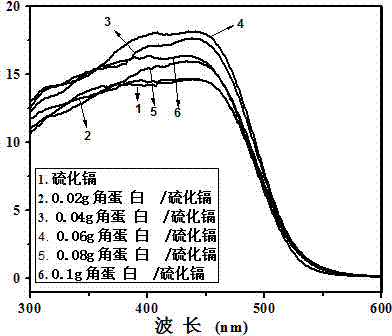

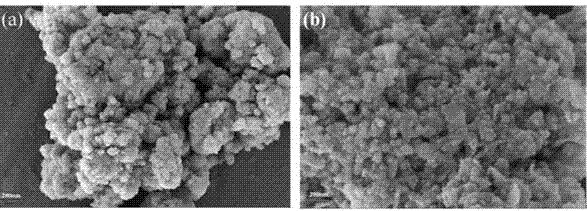

[0046] Weigh 0.02 g of feather keratin, disperse it in 10 ml of 2 mol / L urea solution, and bathe in water at 65°C for 30 min to obtain a completely soluble feather keratin solution; add 0.004 g of dithiothreitol (DDT), Stir for 10 min; then add 20ml of Cd(Ac) successively under stirring 2 2H 2 O solution (0.01M), 20ml Na 2 S aqueous solution (0.01), sonicated for 30 min, and then the mixed solution was placed in a water bath at 80 °C for 8 h, the product was washed with distilled water and absolute ethanol, and dried at 60 °C for 12 h to obtain the FK / CdS composite material, in which feather keratin ( FK) accounted for 1.37% respectively. The degradation rate of rhodamine B is 60%.

Embodiment 2

[0048] Weigh 0.04 g of feather keratin, disperse it in 10 ml of 2 mol / L urea solution, and bathe in water at 65°C for 30 min to obtain a completely soluble feather keratin solution; add 0.004 g of dithiothreitol (DDT), Stir for 10 min; then add 20ml of Cd(Ac) successively under stirring 2 2H 2 O solution (0.01M), 20ml Na 2 S aqueous solution (0.01), sonicated for 30 min, and then the mixed solution was placed in a water bath at 80 °C for 8 h, the product was washed with distilled water and absolute ethanol, and dried at 60 °C for 12 h to obtain the FK / CdS composite material, in which feather keratin ( FK) accounted for 2.70% respectively. The degradation rate of Rhodamine B is 80%.

Embodiment 3

[0050] Weigh 0.06 g of feather keratin, disperse it in 10 ml of 2 mol / L urea solution, and bathe in water at 65°C for 30 min to obtain a completely soluble feather keratin solution; add 0.004 g of dithiothreitol (DDT), Stir for 10 min; then add 20ml of Cd(Ac) successively under stirring 2 2H 2 O solution (0.01M), 20ml Na 2 S aqueous solution (0.01), sonicated for 30 min, and then the mixed solution was placed in a water bath at 80 °C for 8 h, the product was washed with distilled water and absolute ethanol, and dried at 60 °C for 12 h to obtain the FK / CdS composite material, in which feather keratin ( FK) accounted for 3.99% respectively. The degradation rate of Rhodamine B is 98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com