Electromagnetic one-dimensional constant force device and its control method

A technology of constant force device and control method, which is applied to grinding automatic control devices, manufacturing tools, and parts of grinding machine tools, can solve the problems of high cost, inability to track fluctuations, and high working noise, and achieve production The effect of low cost, strong adjustability and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

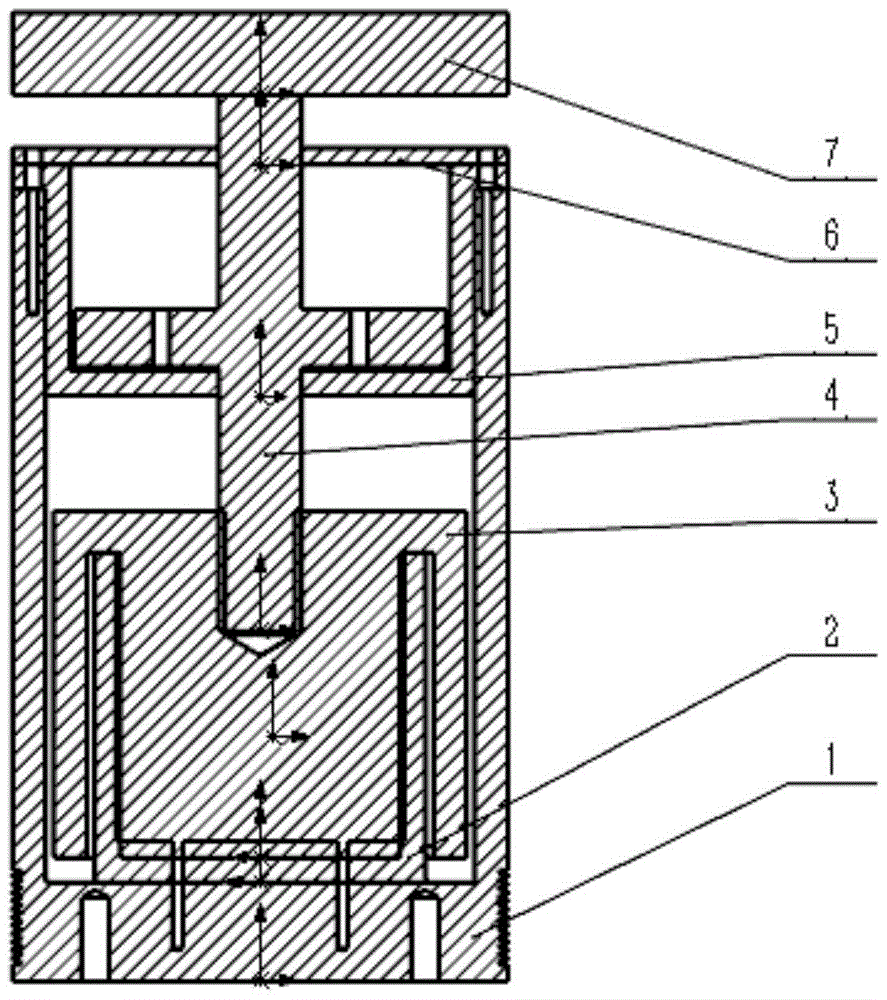

[0066] refer to figure 1 , an electromagnetic one-dimensional constant force device, including a base 1, a voice coil motor, a push rod 4, an end cover 5, a cover 6 and a controller, the push rod 4 is a cross-shaped structure, and the base 1 is a cylindrical structure with a sealed bottom , the voice coil motor is set in the base 1, the end cover 5 and the cover 6 are installed on the top of the base 1 in sequence, the end cover 5 is concave toward the bottom of the base 1 and forms a limiting space with the cover 6, One end of the push rod 4 passes through the end cover 5 and is connected to the voice coil motor. The other end of the push rod 4 protrudes from the cover 6 and a sensor module 7 is installed at the end. Driven by the voice coil motor, the push rod 4 moves in the limited space Inwardly moving, the end cover 5 plays a limiting role on the beam of the push rod 4;

[0067] The sensor module 7 is used to collect the force signal and attitude signal of the constant f...

Embodiment 2

[0075] The control method of the electromagnetic one-dimensional constant force device of Embodiment 1 includes:

[0076] S1. Obtain the constant force between the constant force device set by the user and the workpiece;

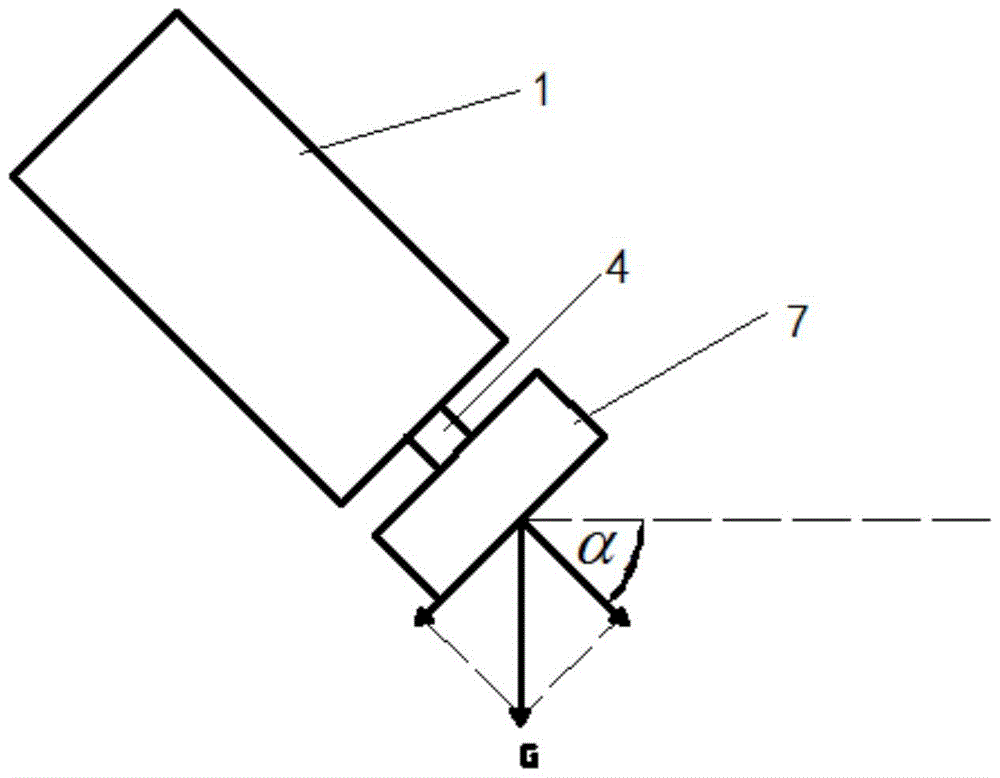

[0077] S2. Obtain the real-time force signal and attitude signal of the constant force device collected by the sensor module 7. The sensor module 7 includes a one-dimensional force sensor for collecting the force signal of the constant force device and an attitude signal for collecting the constant force device. The three-axis gyroscope;

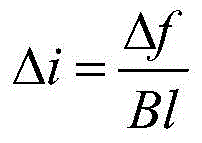

[0078] S3. Calculate the target force signal of the sensor module 7 in combination with the set constant force and the acquired attitude signal, specifically:

[0079] According to the following formula, the target force signal of the one-dimensional force sensor is calculated by combining the set constant force and the acquired attitude signal:

[0080] f 目标 = f 接 +m 2 gsin(α)

[0081] Among them, f 目标 Represents t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com