Copper ore wastewater treatment process

A copper mine wastewater treatment technology, applied in mining wastewater treatment, water/sewage treatment, special compound water treatment, etc., can solve the problems of slow efficiency and high cost of copper mine wastewater treatment, to speed up treatment efficiency and reduce wastewater retention time, the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A copper mine wastewater treatment process, characterized in that it comprises the following steps:

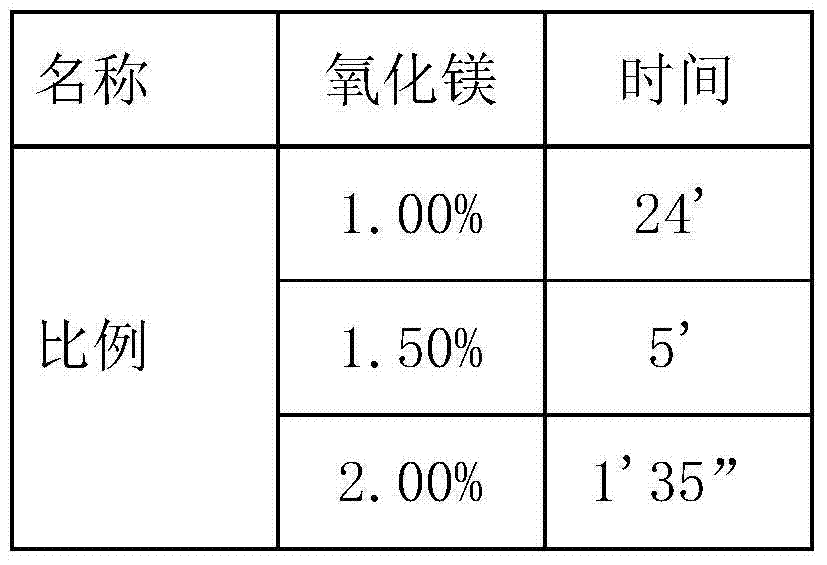

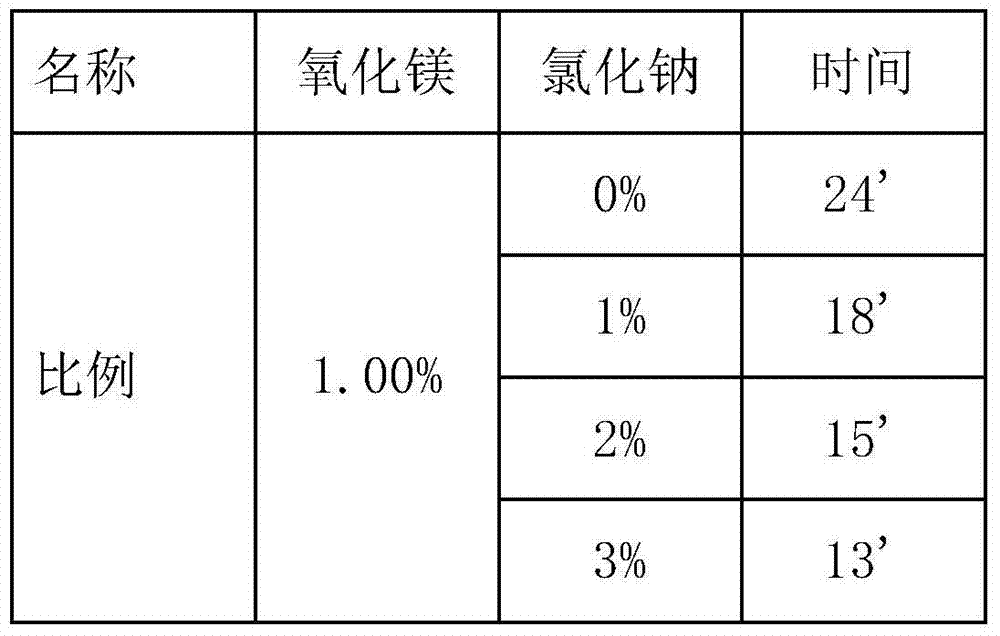

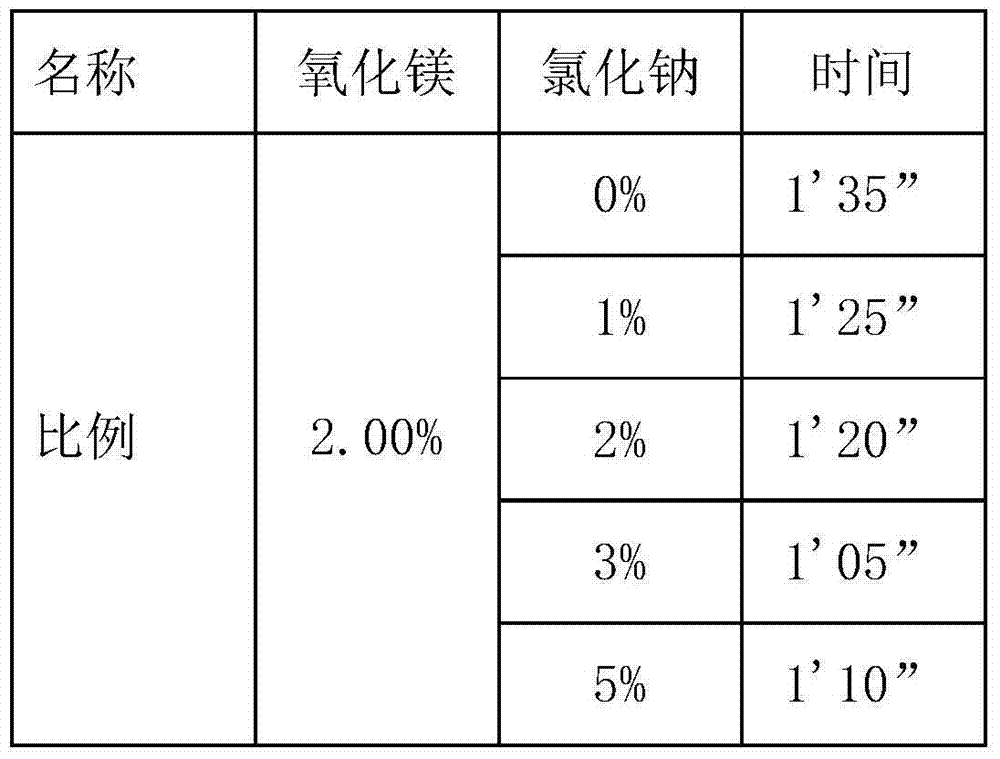

[0016] 1) Add 1%-3%w / w magnesium oxide and 1%-5%w / w industrial salt in the sedimentation tank, the industrial salt is sodium chloride, and the best addition amount is 3%w / w , where w / w is the mass fraction.

[0017] 2) The magnesium oxide and sodium chloride are mixed with the copper mine wastewater by aeration or stirring.

[0018] 3) Mix and stir magnesium oxide, sodium chloride and copper mine waste water for a period of 2-5 minutes, let magnesium oxide react with water during stirring to generate magnesium hydroxide, copper ions and other trace heavy metals in magnesium hydroxide and copper mine waste water The ions react to form precipitates and suspended solids, and at the same time, sodium chloride reacts with magnesium oxide to accelerate the dissolution of magnesium oxide.

[0019] 4) After the stirring is stopped, the sediment in the wastewater is allowed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com