Kitchen waste treatment and composting system

A kitchen waste and pre-treatment technology, applied in organic fertilizers, climate change adaptation, etc., can solve problems such as waste of reusable resources, threats to people's health and safety, soil and groundwater pollution, etc., to achieve simple structure, shorten biological The effect of high degradation time and crushing fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The above content is only to illustrate the technical idea of the present invention, and cannot limit the protection scope of the present invention. Any changes made on the basis of the technical solution according to the technical idea proposed in the present invention shall be regarded as the protection scope of the present invention; The technology not involved in the invention can be realized by the existing technology.

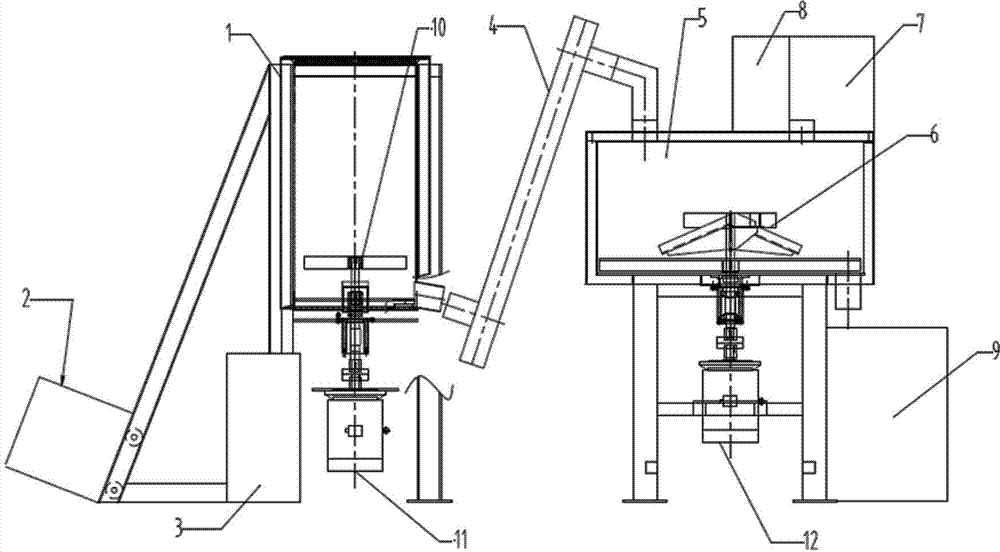

[0022] see figure 1 The shown kitchen waste treatment and fertilizer making system includes a pre-processing box 1. The box structure of the pre-processing box 1 described in the present model is a double-chamber sheet metal structure, and the inner chamber is a honeycomb structure. This is conducive to compact structure and improved oil-water separation effect. A moving automatic feeding mechanism 2 is installed on one side of the pre-processing box 1, and the bottom of the pre-processing box 1 is equipped with a crushing tool rotating disk 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com