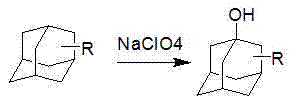

Preparation method of adamantanol compound

A technology of adamantanol and adamantane methanol, which is applied in the field of preparation of adamantanol compounds, can solve problems such as inability to use sulfuric acid solution, difficult treatment, and excessive waste water, and achieve the effects of environmental friendliness, low cost, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 600ml of 20% sodium perchlorate solution in a 1000ml four-necked flask, add 60g of adamantane under stirring, and react at 40°C for 6 hours after adding; Qualitative confirmation was carried out against standard data, and quantitative analysis was carried out with standard products by gas chromatography (GC). At this time, the content of adamantane in the reaction solution was 0.6%, and the content of 1-adamantanol was 98.7%.

[0028] Cool to 5-10°C and stir for 2 hours, filter, wash with 50ml of cold water at 10°C, wash with 30ml of cold ethanol at 10°C, and dry at 90°C to obtain 63.5g of 1-adamantanol with a yield of 94.7%, analyzed by GC The content is 99.8%.

Embodiment 2

[0030] Except that 60g of 1-adamantanol was used instead of adamantane, and the reaction temperature was 70°C, the rest of the operations were the same as in Example 1. As a result, 62.7g of 1,3-adamantanediol was obtained with a yield of 94.5% and a GC analysis content of 99.6%. .

Embodiment 3

[0032] Except that 60 g of 1-methyladamantane was used instead of adamantane, and the reaction temperature was 60° C., the rest of the operations were the same as in Example 1. As a result, 61.8 g of 3-methyl-1-adamantanol was obtained, and the yield was 93.1%. GC analysis The content is 99.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com