High-scorch-resistance peroxide curing system rubber composition and preparation method thereof

A technology of rubber composition and peroxide, which is applied in the field of rubber, can solve the problems of affecting the vulcanization and molding of rubber materials, the rapid decline of tensile strength, and the inability to effectively prolong the scorch time of rubber materials, so as to reduce energy consumption and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

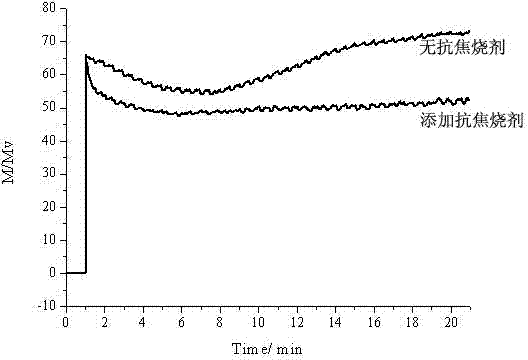

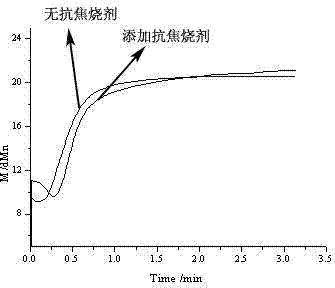

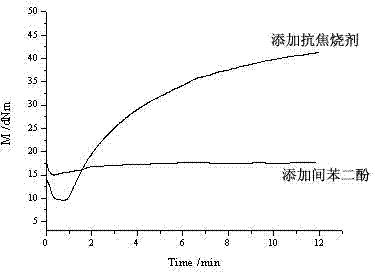

Image

Examples

Embodiment 1

[0024] Formula is by weight:

[0025] EPDM: 100 phr;

[0026] Antiaging agent RD (2,2,4-trimethyl-1,2-dihydroquinoline polymer): 1.0 phr;

[0027] Carbon black and light calcium carbonate: 40 phr;

[0028] Paraffin oil: 10 phr;

[0029] Cross-linking agent BPO (dibenzoyl peroxide): 1.0 phr;

[0030] Anti-scorch agent: 1,1-diphenyl-2-pichydrazine 0.05 phr.

[0031] The above formula was prepared as a rubber composition sample according to the following process, and the performance was tested.

[0032] Step 1: Turn on the open mill or internal mixer, add rubber first, then add anti-aging agent, add fillers and plasticizers after 2 minutes of refining, 3-5 minutes of refining, release the tablets and park for 12 hours;

[0033] Step 2: Turn on the open mill or internal mixer, control the temperature at 50-80°C, soften the rubber obtained in the first step for 1 minute, add crosslinking agent and anti-scorch agent to refine for 3 minutes, and then beat After 5 times of t...

Embodiment 2

[0036] Formula is by weight:

[0037] EPDM: 100 phr;

[0038] Antiaging agent RD: 1.0 phr;

[0039] Carbon black and light calcium carbonate: 40 phr;

[0040] Paraffin oil: 10 phr;

[0041] Cross-linking agent BPO1.0 phr;

[0042] Anti-scorch agent: 2,2,6,6-tetramethylpiperidine nitrogen oxide 0.25 phr.

[0043] The above formula was prepared as a rubber composition sample according to the process of Example 1, and the performance was tested.

Embodiment 3

[0045] Formula is by weight:

[0046] EPDM: 100 phr;

[0047] Antiaging agent RD: 1.0 phr;

[0048] Carbon black and light calcium carbonate: 40 phr;

[0049] Paraffin oil: 10 phr;

[0050] Cross-linking agent BPO: 1.0 phr;

[0051] Anti-scorch agent: tert-butylcatechol 0.5 phr.

[0052] The above formula was prepared as a rubber composition sample according to the process of Example 1, and the performance was tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com