Method for growing ultra-strong light absorption carbon nano tube coating on titanium alloy substrate

A technology of carbon nanotubes and titanium alloys, which is applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., to achieve the effect of enhancing the firmness and serialization degree, reducing the overall size and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

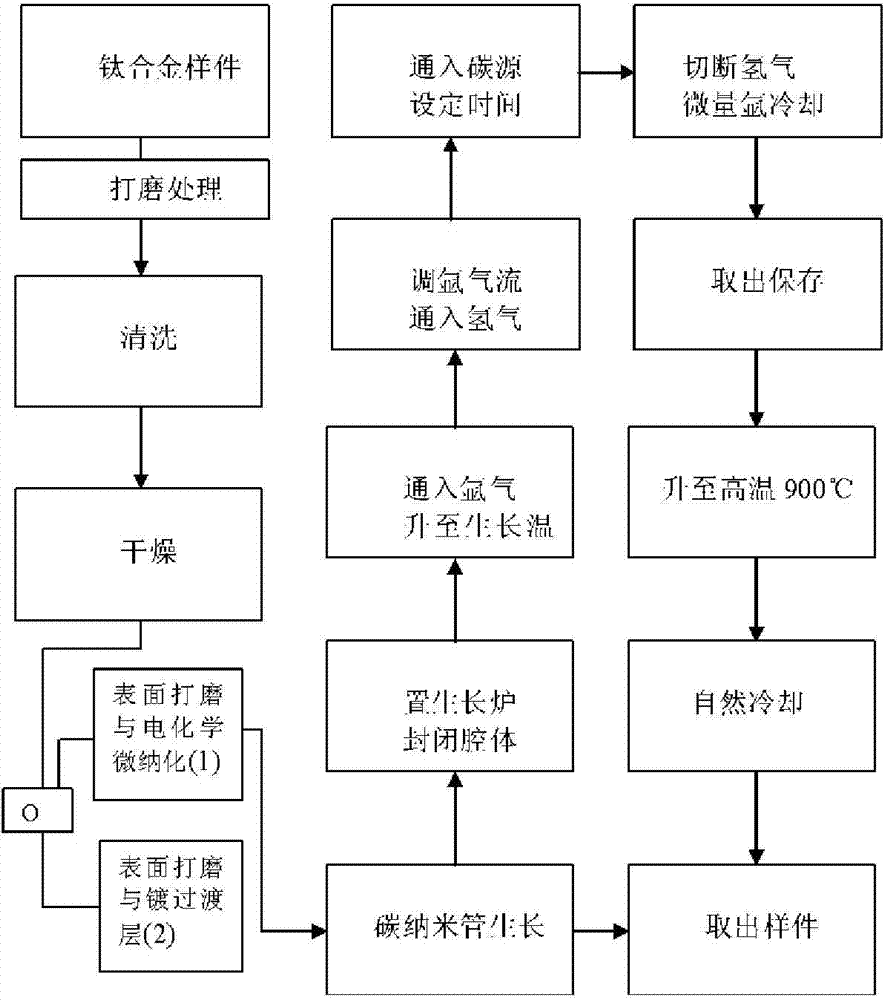

[0028] Such as figure 1 Shown, be the flow chart diagram of the inventive method, main steps are as follows:

[0029] 1) Use ultra-fine sandpaper or similar grinding methods to roughen the surface of the titanium alloy sample, so that the surface of the polished titanium alloy sample has fine scratches, which is beneficial to the growth of carbon nanotubes (CNT, Carbon Nanometer Tube);

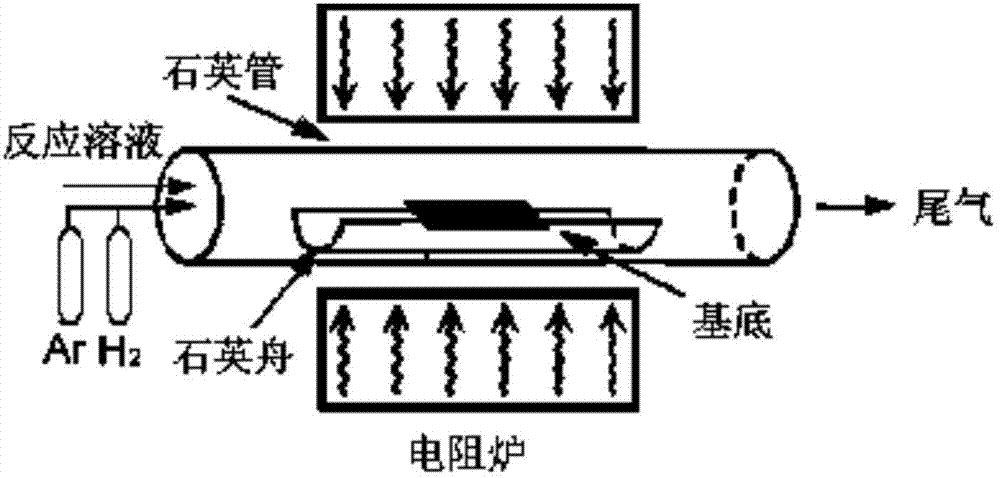

[0030] 2) Clean the polished titanium alloy sample with an organic solvent such as alcohol or acetone to remove organic pollutants, such as oil stains and fouling, in order to prevent the organic matter volatilized at high temperature from affecting the reaction between the carbon source and the catalyst, and Prevent pollution of carbon nanotube reactor after cooling (such as figure 2 Shown) the quartz tube wall;

[0031] 3) After the organic cleaning is completed, put the titanium alloy sample into a drying oven for drying, and the drying temperature is controlled below 150°C, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com