A tornado cyclone electrospinning nozzle device for preparing nano-twisted yarns

An electrospinning and cyclone-type technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve problems such as difficult to achieve micro-nano level twisting, complex device structure, complex structure, etc., and achieve process saving , The structure of the nozzle is simple, and the twisting method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

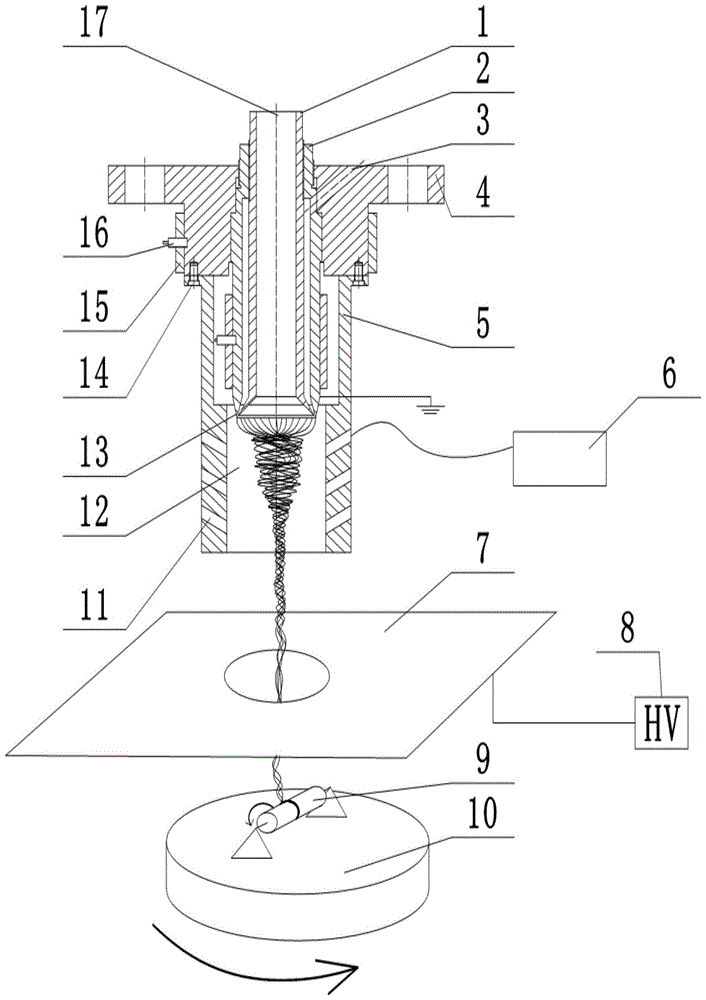

[0015] A kind of tornado cyclone type preparation nano-twist electrospinning nozzle device of the present invention proposes to utilize the tangential airflow hole 11 of air cylinder 5 and the vertical airflow inlet 17 of airflow conduit 1 to connect air compressor 6 and pass into airflow in The coupling in the inner chamber 12 of the blower produces a downward moving tornado, which drives the fibers to rotate and twist; further, different types of tornadoes are generated by controlling the flow velocity of the vertical airflow and tangential airflow, and finally realizes Different twisting requirements for electrospun nanofibers.

[0016] A tornado cyclone type electrospinning nozzle device for preparing nano-twisted yarns according to the present invention, the schematic diagram of the device is as follows figure 1 As shown, it mainly includes airflow conduit 1, spinning barrel 2, connector 4, air cylinder 5, air compressor 6, hole electrode plate 7, high-voltage electrostat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com