Reinforcing structure of reinforced concrete arch bridge main arch ring

A technology of reinforced concrete and reinforced structure, applied in the direction of bridge reinforcement, arch bridges, bridges, etc., can solve the problems of the influence of traffic conditions under the bridge, high consumption, long cost recovery period, etc., to reduce the overall labor intensity and improve the compressive bearing capacity , the effect of reducing the overall working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

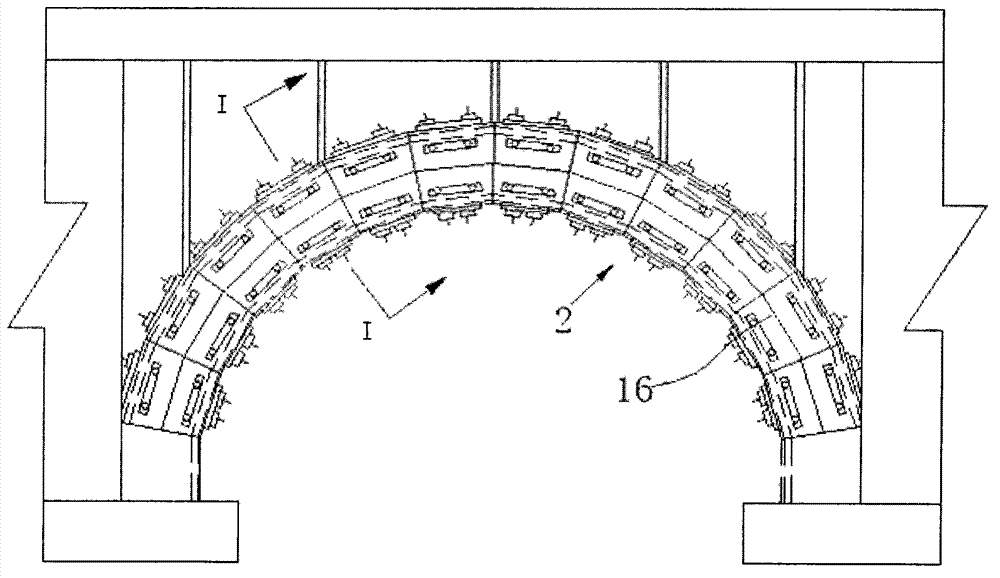

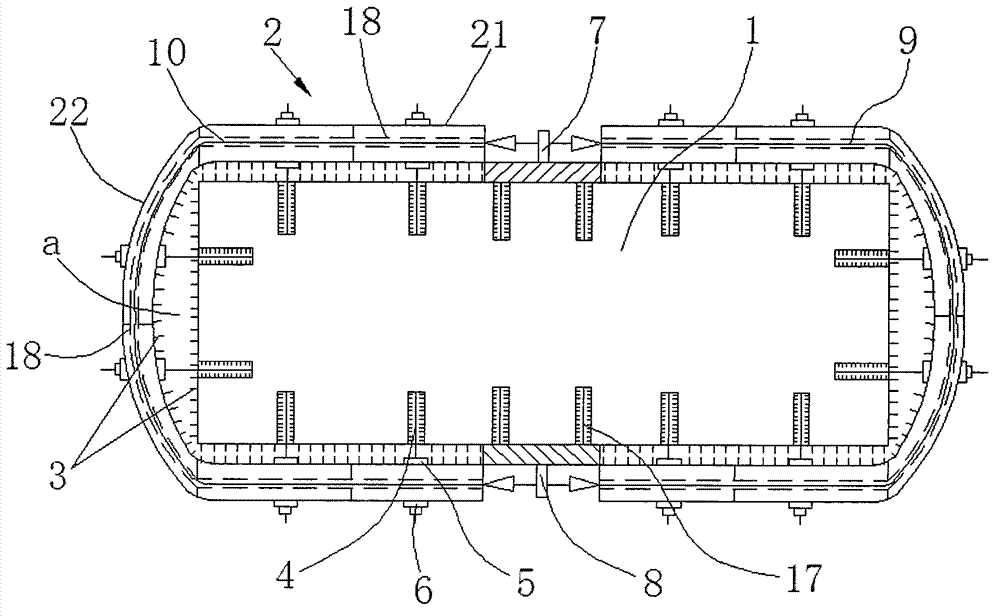

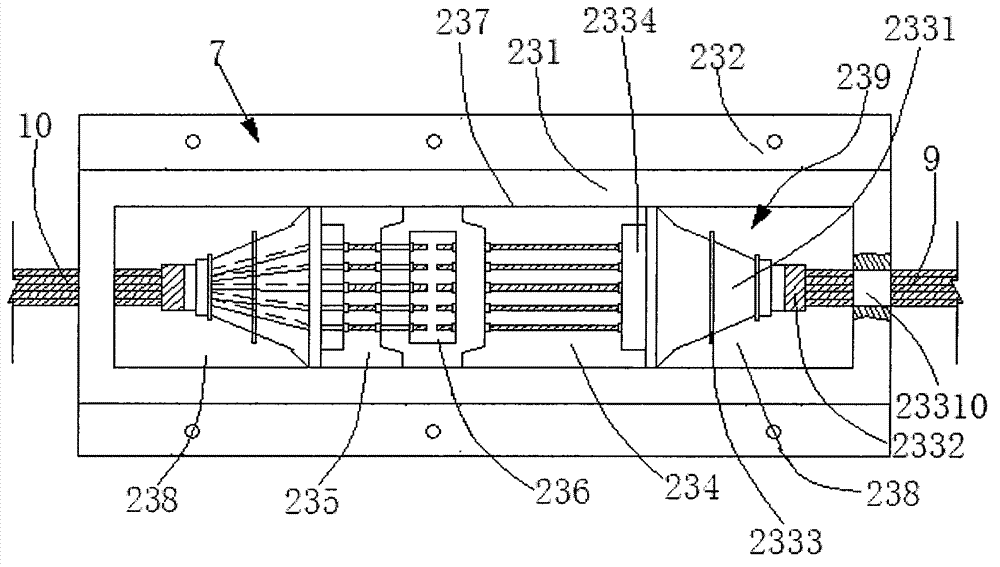

[0026] see Figure 1-6 , a reinforcement structure for the main arch ring of a reinforced concrete arch bridge, which includes a prefabricated concrete surface formwork 2 extending along the concrete main arch circle 1 direction of the arch bridge, the surface formwork 2 is composed of several formwork sections 16, and the formwork sections 16 It is a formwork system composed of a circle of formworks connected to each other. The middle parts of the top and bottom sides of the formwork section 16 are respectively fixed with a first steel anchor box 7 and a second steel anchor box 8 arranged symmetrically. Between the first steel anchor box 7 and the second steel anchor box 8, the surface template working section 16 is integrally tensioned and fixed into one by the first prestressed steel strand 9 and the second prestressed steel strand 10, and the template Working section 16 is made up of plane formwork 21 and arc formwork 22, and the middle part of described plane formwork 21 ...

Embodiment 2

[0039] see Figure 1-6 , a construction method for reinforcing the main arch ring of a reinforced concrete arch bridge, which is realized through the following steps:

[0040] 1) Clean up the damaged concrete surface of the concrete main arch ring 1 of the arch bridge, roughen the surface, and plant shear pins 3 to ensure that the old and new concrete work together;

[0041] 2) Find out the center line of the top and bottom surfaces of each formwork section 16 of the arch bridge concrete main arch ring 1, and then implant threaded steel bars 17 on the upper top surface and lower bottom surface of the center line of the arch bridge concrete main arch ring 1 working section, and then pass the threaded steel bars Fix the pre-embedded load-bearing plate, weld and fix the force-transmitting steel plate 231 in the first steel anchor box 7 or the second steel anchor box 8 and the load-bearing plate (finally pouring concrete to wrap the first steel anchor box 7 or the second steel anc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com