A pm2.5 source apportionment sampling device based on flow feedback control

A technology of feedback control and sampling device, which is applied in the direction of sampling device, etc., can solve the problems of single flue gas sampling method and inability to accurately control the dilution ratio, and achieve the effects of easy promotion, reduced manufacturing difficulty, and stable flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

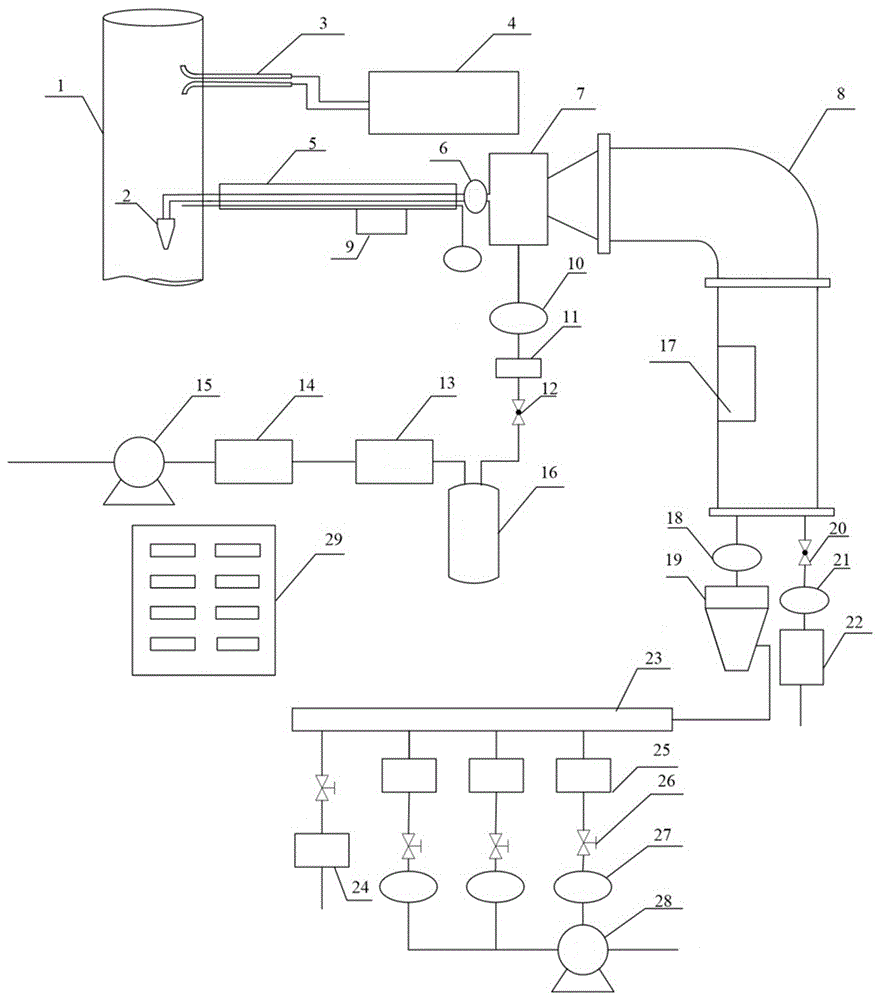

[0024] Such as figure 1 As shown, the PM2.5 source apportionment sampling device based on flow feedback control in this embodiment includes a flue gas collection component, a mixing and dwelling chamber, a PM cutter 19, and a sampling and analysis unit.

[0025] The flue gas collection component is a unit for collecting flue gas, which is directly installed in the pipeline of the pollution source to collect the flue gas in the pipeline; the mixing and dwelling chamber is the area where the flue gas and the dilution gas are mixed and lodged, specifically including the dilution tank 7 and the dwelling chamber 8. The dilution tank 7 and the residence chamber 8 are connected to each other, the flue gas collection component is connected to the dilution tank 7, and the residence chamber 8 is connected to the sampling and analysis unit through the PM cutter 19.

[0026] In this embodiment, a second flowmeter 6 and an air delivery unit are also included. The second flowmeter 6 is arra...

Embodiment 2

[0029] As a further solution of Embodiment 1, in this embodiment, a third flow meter 18, an emptying pipeline and a fourth flow meter 21 are also provided, and the third flow meter 18 is provided and connected to the residence chamber 8 and the PM cutter 19 Between them, the emptying pipeline is led out from the dwelling chamber 8, and is connected to the second proportional valve 20, the fourth flow meter 21 and the particulate matter filter 22 in sequence, and then is emptied.

[0030] In this embodiment, the third flowmeter 18 and the fourth flowmeter 21 are set to accurately monitor the gas volume at the outlet of the dwelling chamber 8. Since the PM in the flue gas has aging problems in the air, the sampling process will be based on different Sampling requirements require different precise flow control. Once the flow rate entering the residence chamber 8 is greater than the sampling flow rate, the pressure of the residence chamber 8 will increase, resulting in an increase ...

Embodiment 3

[0033] In this embodiment, the structure of the front part is the same as that of Embodiment 1 or Embodiment 2, and the sampling analysis unit specifically includes a split chamber 23, a PM analyzer 24, a PM collector 25, a ball valve 26, a flow meter 27, a sampling pump 28, a split chamber 23 is respectively connected to PM analyzer 24 and PM collector 25, and PM collector 25 is connected to sampling pump 28 through ball valve 26 and flow meter 27 in turn. Such as figure 1 As shown, according to needs, multiple PM collectors 25 can be drawn out from the split chamber 23, and three are provided in this embodiment, and a ball valve 26 and a flow meter 27 are respectively provided correspondingly, and finally connected to the sampling pump 28.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com