Rectifier valve bank unit of extra-high voltage ground wire direct-current deicing device

A DC ice-melting and UHV technology, applied to electrical components, overhead installation, electrical solid devices, etc., can solve problems such as difficult maintenance, complex structure, assembly process, and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

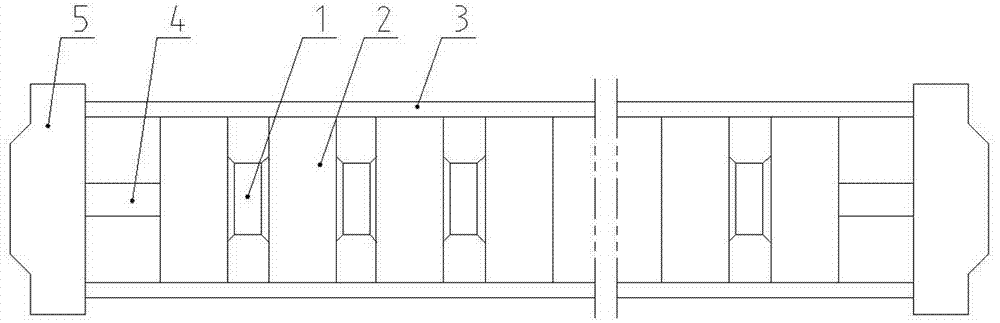

[0011] Such as figure 1 As shown, the present invention discloses a rectifier valve group unit of a UHV ground line DC ice melting device, including a rectifier tube 1, a radiator 2, an epoxy support plate 3, an epoxy threaded tube 4 and a stainless steel pressure plate 5. Several rectifying tubes 1 and radiators 2 are alternately arranged and vertically crimped, and one rectifying tube 1 is sequentially crimped in the middle of two adjacent radiators 2 . The two ends of each radiator 2 are respectively connected into one body through epoxy support plates 3 to ensure the withstand voltage requirement between two adjacent radiators 2 . The epoxy threaded pipe 4 is vertically connected to the outside of the first and last radiator 3 , and the stainless steel pressure plate 5 is vertically connected to the outer end of the epoxy threaded pipe 4 . The two ends of the stainless steel pressure plate 5 are respectively connected with the corresponding epoxy support plate 3 as a whol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com