A kind of nickel slag fly ash foam glass and preparation method thereof

A technology of foam glass and fly ash, which is applied in the field of foam glass, can solve the problems of high volume density and achieve the effects of low density, energy saving, and good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

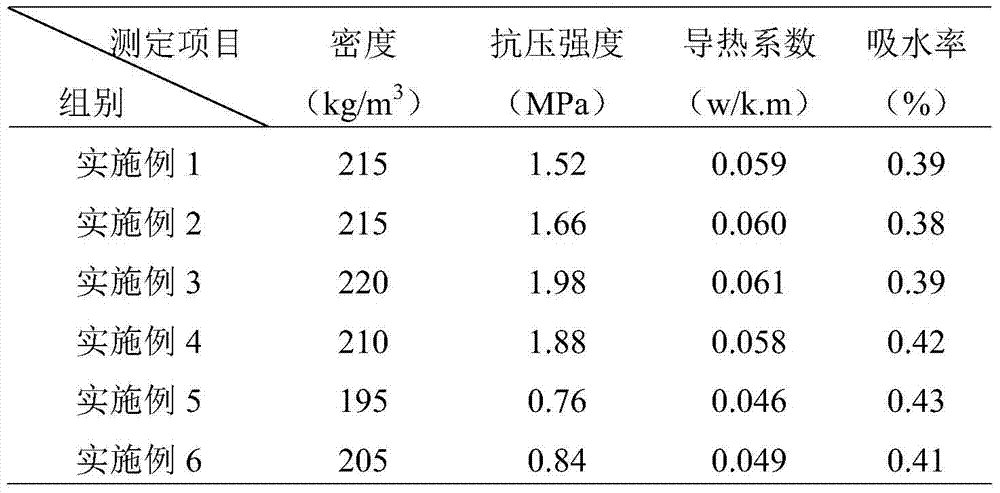

Examples

Embodiment 1

[0027] Ratio: 20 parts by weight of nickel slag, 20 parts by weight of fly ash, 50 parts by weight of waste glass, 4 parts by weight of carbon black, 3 parts by weight of sodium fluorosilicate, 3 parts by weight of boric acid

[0028] Preparation:

[0029] (1) After the waste glass is washed and dried, it is crushed to less than 10mm, and the nickel slag is crushed to 5mm, and then set aside;

[0030] (2) Weigh nickel slag, fly ash, waste glass, foaming agent, foam stabilizer and flux according to the formula, grind for 20-50min to obtain mixture powder, and pass through a 200-mesh sieve;

[0031] (3) Put the powder obtained in step (2) into a high-temperature-resistant mold coated with a release agent on the inside, and place it on a vibration table to vibrate compactly;

[0032] (4) Separate the cutters with equal side lengths, and vertically divide the shaken powder in step (3) into several small pieces;

[0033] (5) Put the high-temperature-resistant mold after step (4) ...

Embodiment 2

[0035] Proportions: 40 parts by weight of nickel slag, 20 parts by weight of fly ash, 30 parts by weight of waste glass, 4 parts by weight of limestone, 3 parts by weight of borax, and 3 parts by weight of sodium phosphate

[0036] Preparation:

[0037] (1) After the waste glass is washed and dried, it is crushed to less than 10mm, and the nickel slag is crushed to 5mm, and then set aside;

[0038] (2) Weigh nickel slag, fly ash, waste glass, foaming agent, foam stabilizer and flux according to the formula, grind for 20-50min to obtain mixture powder, and pass through a 200-mesh sieve;

[0039] (3) Put the powder obtained in step (2) into a high-temperature-resistant mold coated with a release agent on the inside, and place it on a vibration table to vibrate compactly;

[0040] (4) Separate the cutters with equal side lengths, and vertically divide the shaken powder in step (3) into several small pieces;

[0041] (5) Put the high-temperature-resistant mold after step (4) int...

Embodiment 3

[0043] Ratio: 40 parts by weight of nickel slag, 20 parts by weight of fly ash, 30 parts by weight of waste glass, 4 parts by weight of sodium carbonate, 3 parts by weight of sodium fluorosilicate, 3 parts by weight of boric acid

[0044] Preparation:

[0045] (1) After the waste glass is washed and dried, it is crushed to less than 10mm, and the nickel slag is crushed to 5mm, and then set aside;

[0046] (2) Weigh nickel slag, fly ash, waste glass, foaming agent, foam stabilizer and flux according to the formula, grind for 20-50min to obtain mixture powder, and pass through a 200-mesh sieve;

[0047] (3) Put the powder obtained in step (2) into a high-temperature-resistant mold coated with a release agent on the inside, and place it on a vibration table to vibrate compactly;

[0048] (4) Separate the cutters with equal side lengths, and vertically divide the shaken powder in step (3) into several small pieces;

[0049](5) Put the high-temperature-resistant mold after step (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com