Rotor structure of a high-speed permanent magnet synchronous motor

A permanent magnet synchronous motor and rotor structure technology, applied in synchronous machine parts, magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc. problems, to reduce the cost of the motor, suppress the current distortion, and optimize the manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

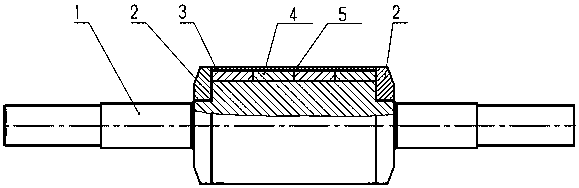

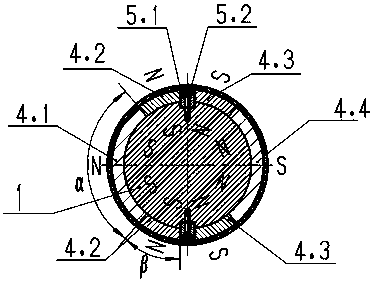

[0021] refer to figure 1 , figure 2 As shown, the invention discloses a rotor structure of a high-speed permanent magnet synchronous motor, including a rotating shaft 1, an end plate 2, a sheath 3 and a magnet 4. The rotating shaft 1 uses a magnetic material to provide a magnetic circuit for the rotor. The rotating shaft 1 The outer surface of the middle section is provided with a groove, and a positioning key 5 is installed in the groove to fix the magnet 4. The positioning key 5 is composed of a flat key 5.1 and a screw 5.2, and is used for positioning the magnet 4 and transmitting torque. The magnetic material is fixed on both sides of the middle section of the rotating shaft 1 through interference fit, and is used for the axial fixation of the magnet 4. After the magnet 4 is installed, the sheath 3 is bound on the outer surface. The sheath 3 is a compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com