Communication equipment metal shell and manufacturing method thereof

A technology for communication equipment and metal shells, applied in the field of metal shells of communication equipment and its preparation, can solve the problems of easy damage, deformation, unfavorable production, etc., and achieve the effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

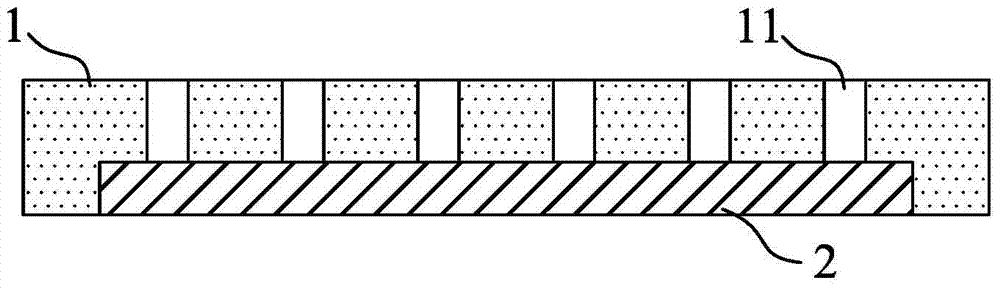

[0036] The metal shell of the communication equipment provided by the present invention can be prepared by the following preparation method, which specifically includes:

[0037] S1. Provide a metal substrate, the metal substrate is provided with a plurality of slits; the width of the slit is 5-40 μm, and the distance between two adjacent slits is 0.3-1.6 mm;

[0038]S2. Roughening the inner surface of the metal matrix at the position where the gap is located to form a metal shell; there are multiple micropits on the inner surface of the metal shell;

[0039] S3. Inject resin on the inner surface of the metal shell where the gap is located to form a plastic part.

[0040] In step S1, the metal base can be purchased or obtained by self-processing. It only needs to satisfy that the width of the slit on the metal base is 5-40 μm, and the distance between two adjacent slits is 0.3-1.6 mm.

[0041] If it is processed by itself, various existing cutting methods can be used to cut ...

Embodiment 1

[0063] This embodiment is used to illustrate the metal casing of the communication device disclosed in the present invention and its preparation method.

[0064] Aluminum alloy (grade 6063) is selected as the metal substrate.

[0065] The slits are formed by laser cutting.

[0066] A laser drilling machine (LSF20 laser drilling machine produced by Huagong Laser) is used to process the gaps on the shell. The gap width is 20um, and the distance between adjacent gaps is 0.6mm. The laser processing power is 20W, the speed is 50mm / s, the frequency is 30kHz, and the wavelength is 1064nm.

[0067] to obtain a metal substrate.

[0068] Degreasing, water washing, alkali etching, water washing, pickling, and water washing are performed on the above metal substrate, and then immersed in the pretreatment solution for 5 minutes of pretreatment, and baked at 80°C for 20 minutes to complete the pretreatment process.

[0069] Then prepare 500ml of 10% hydrochloric acid solution in a beaker...

Embodiment 2

[0080] This embodiment is used to illustrate the metal casing of the communication device disclosed in the present invention and its preparation method.

[0081] Aluminum alloy (grade 6063) is selected as the shell material.

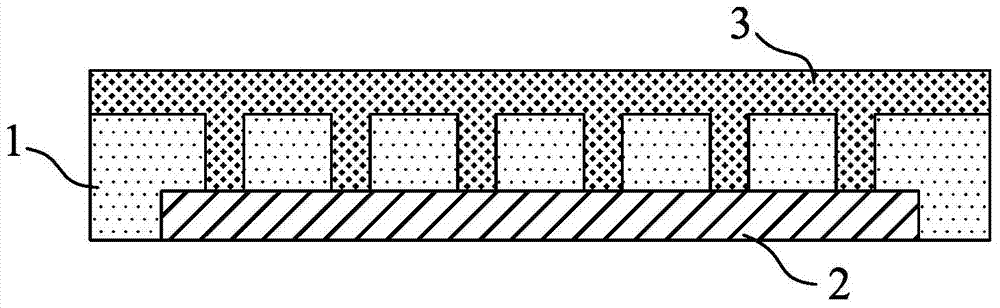

[0082]The metal casing and the plastic parts were prepared according to the method of Example 1, except that the decorative layer was prepared by the micro-arc oxidation method.

[0083] Degrease the composite of the above metal shell and plastic parts, then immerse in the micro-arc oxidation electrolyte, use the metal shell as the anode, and the stainless steel plate as the cathode, at a voltage of 0-600V and a current density of 5A / dm 2 , micro-arc oxidation at a temperature of 25°C for 30 minutes, and after completion, take it out and clean it with pure water. A metal shell with a micro-arc oxidation layer on the surface is obtained. At this time, the gap is completely covered by the aluminum oxide layer as the micro-arc oxidation layer, which is in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com