Solution of aromatic polyamide for producing display element, optical element, or illumination element

A display element, polyamide technology, applied in the manufacture of display elements, the manufacture of polyamide solutions, optical elements or lighting elements, can not solve problems such as thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

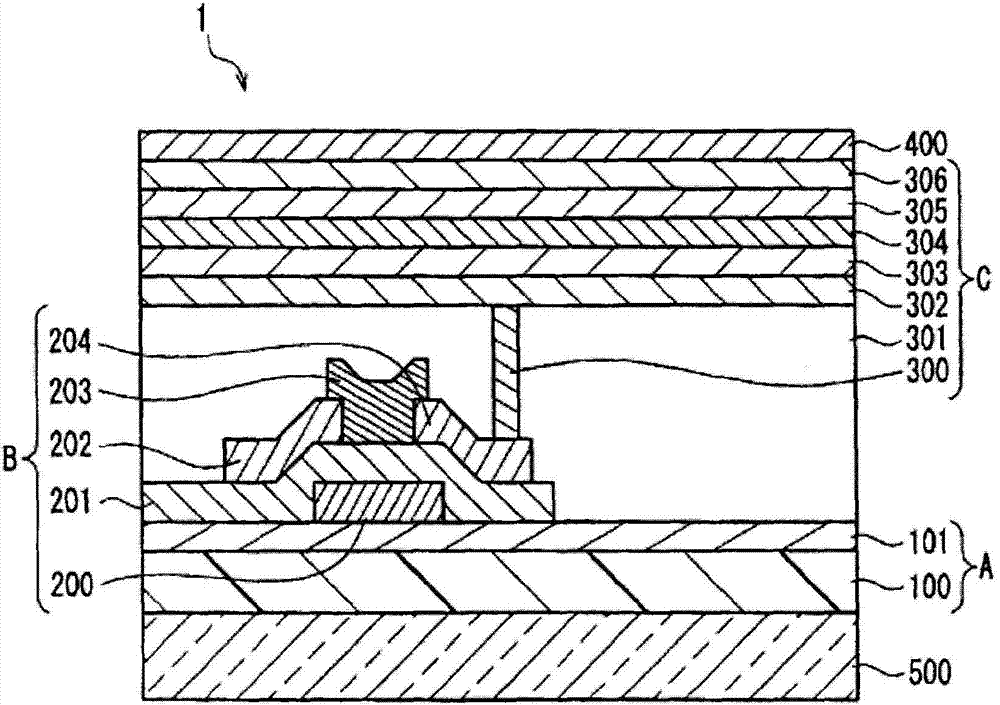

[0086] According to an embodiment of the present disclosure, the method also includes the following steps:

[0087] h) peeling off the display element, optical element or lighting element formed on the substrate from the substrate.

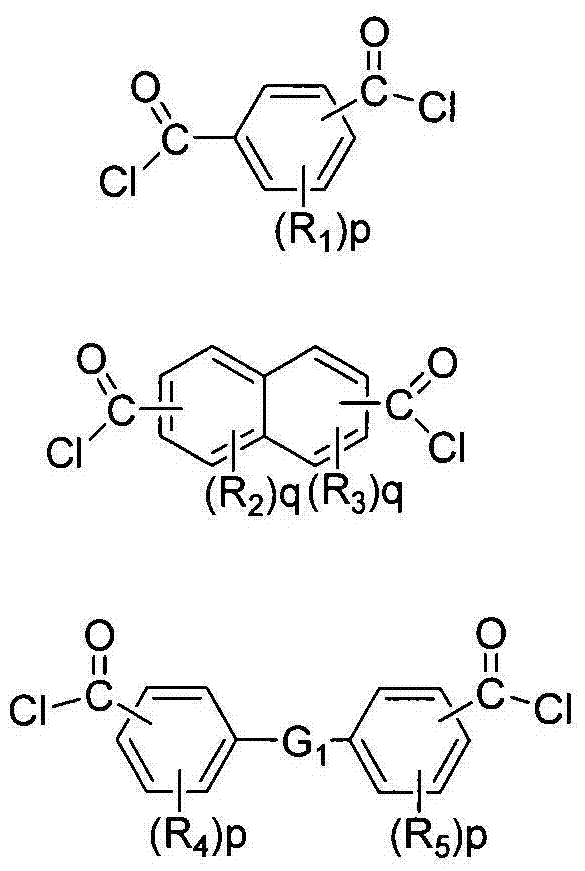

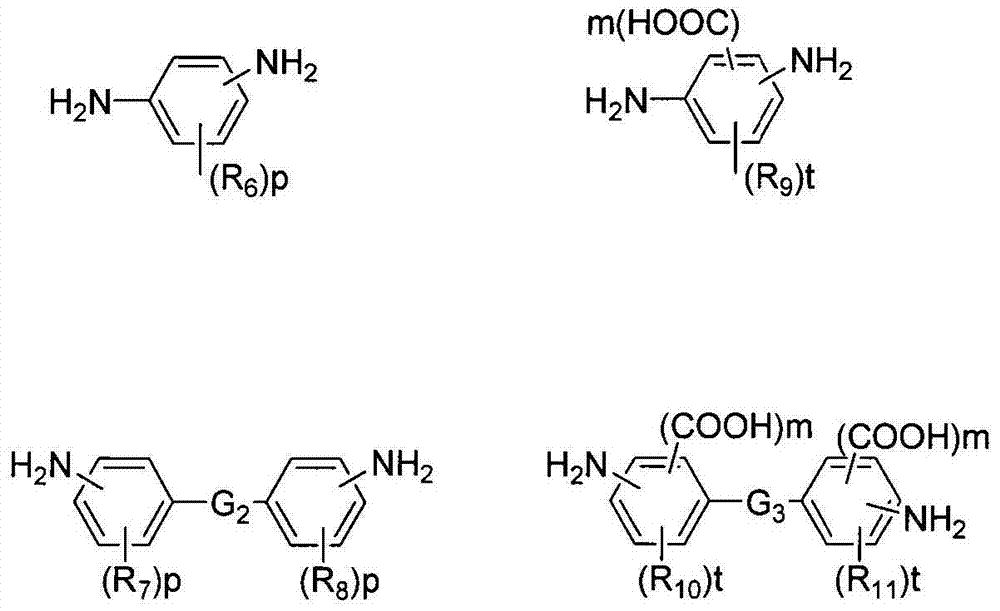

[0088] According to one embodiment of the present disclosure, the aromatic diacid dichloride used in the polymerization of the copolyamide is shown in the following general structure:

[0089]

[0090] where p=4, q=3, and where R 1 , R 2 , R 3 , R 4 , R 5 selected from hydrogen, halogen (fluorine, chlorine, bromine and iodine), alkyl, substituted alkyl such as haloalkyl, nitro, cyano, thioalkyl, alkoxy, substituted alkoxy such as haloalkoxy, aryl radical or substituted aryl such as haloaryl, alkyl and substituted alkyl esters, and combinations thereof. It should be understood that each R 1 can be different for each R 2 can be different for each R 3 can be different for each R 4 can be different, and each R 5 can be different. G 1 s...

Embodiment 1

[0165] Example 1. This example illustrates the general procedure for the preparation of copolymers from TPC, IPC and PFMB (70% / 30% / 100% mol) via solution condensation.

[0166] PFMB (3.2024 g, 0.01 mol) and dry DMAc (45 ml) were added to a 250 ml three necked round bottom flask equipped with a mechanical stirrer, nitrogen inlet and outlet. After PFMB was completely dissolved, IPC (0.6395 g, 0.003 mol) was added to the solution at room temperature under nitrogen, and the flask wall was washed with DMAc (1.5 ml). After 15 minutes, TPC (1.4211 g, 0.007) was added to the solution and the walls of the flask were washed again with DMAc (1.5 ml). The viscosity of the solution increases until the mixture forms a gel. After the addition of PrO (1.4 g, 0.024 mol), the gel collapsed with stirring to form a viscous, homogeneous solution. After an additional 4 hours of stirring at room temperature, the resulting copolymer solution could be cast directly into a film.

Embodiment 2

[0167] Example 2. This example illustrates the general procedure for the preparation of copolymers from TPC, PFMB and FDA (100% / 80% / 20% mol) via solution condensation.

[0168] To a 100 ml four necked round bottom flask equipped with a mechanical stirrer, nitrogen inlet and outlet, was added PFMB (1.0247 g, 3.2 mmol), FDA (0.02788 g, 0.8 mmol) and dry DMAc (20 ml) at room temperature under nitrogen. After PFMB was completely dissolved, TPC (0.8201 g, 4.04 mmol) was added to the solution, and the walls of the flask were washed with DMAc (5.0 ml). The viscosity of the solution increases until the mixture forms a gel. After the addition of PrO (0.5 g, 8.5 mmol), the gel collapsed with stirring to form a viscous, homogeneous solution. After an additional 4 hours of stirring at room temperature, the resulting copolymer solution could be cast directly into a film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com