Winter fresh air system applicable to large-scale hog house in severe cold and cold regions

A cold area, fresh air system technology, applied in ventilation systems, space heating and ventilation, applications, etc., can solve the problems of increased heating energy consumption, increased construction investment, increased operating costs, etc., to achieve less energy consumption and material consumption , The structure is novel and unique, and the effect of increasing airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

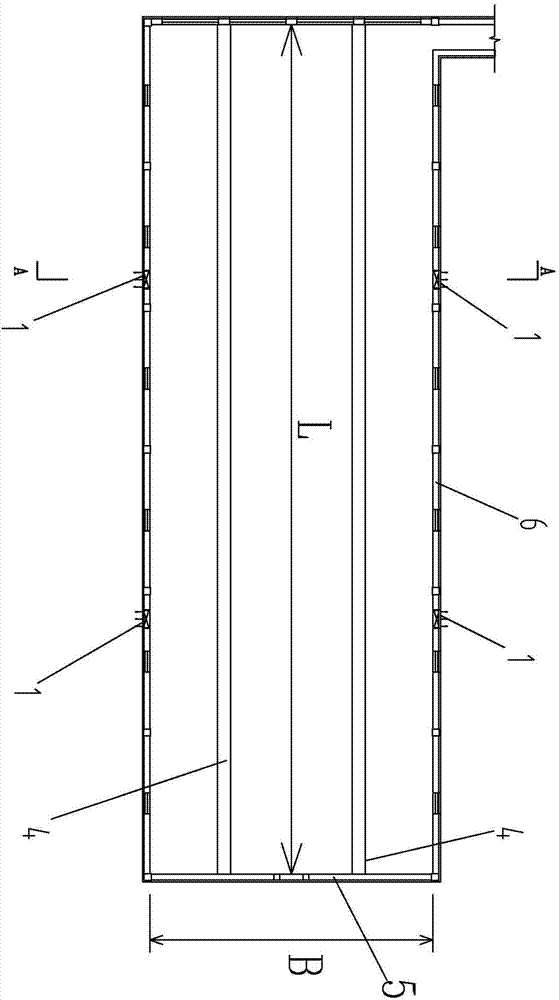

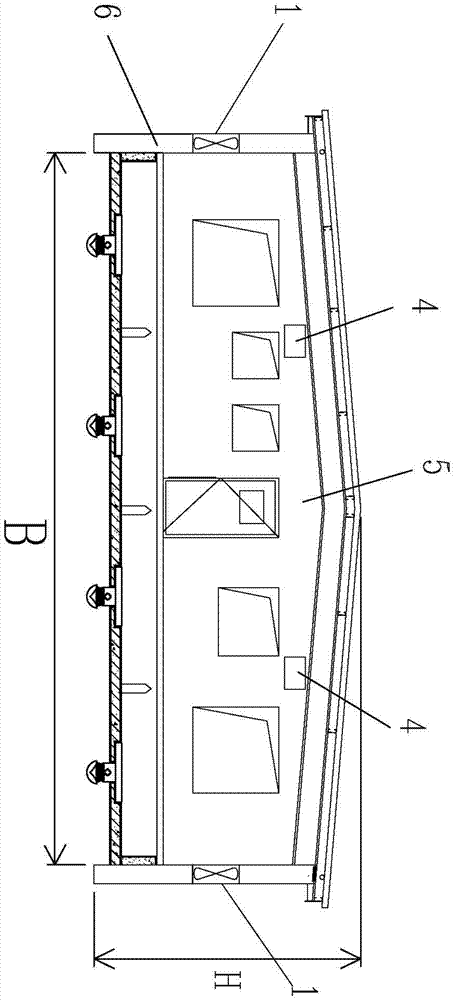

[0046] The length of the pig house L=7.5m; the width of the pig house B=3.5m; the height from the ground to the highest point of the roof is H=2.7m, and the rated air volume of the fan is Q=0.097m 3 / s;

[0047] The length l=7.5m of the fresh air duct of the air duct;

[0048] The length of the section of the fresh air duct is a=0.1m; and the width b=0.07m;

[0049] The length of the air supply hole l 1 =0.12m; width l 2 =0.01m;

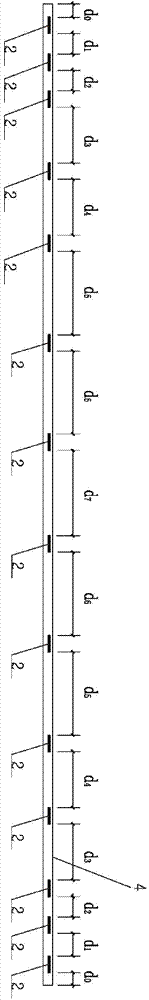

[0050] The number of air supply holes on each side of the fresh air duct n = 14;, the wind speed of the air supply holes v = 1.65m / s; d 0 =0.5m;

[0051]The layout of the air supply holes is symmetrical to the center along the fresh air duct, and the spacing increases from either end of the fresh air duct to the center, between the first air supply hole from the end and the N+1=8th air supply hole The lengths of the unopened part of the air duct side wall are: 0.175m, 0.350m, 0.525m, 0.700m, 0.875m, 1.050m, 2.450m.

Embodiment 2

[0053] The length of the pig house is L=18m; the width of the pig house is B=6.5m; the height from the ground to the highest point of the roof is H=3.0m, and the rated air volume of the fan is Q=0.433m 3 / s;

[0054] The length l=18m of the fresh air pipeline of air duct;

[0055] The length of the section of the fresh air duct a=0.22m; and the width b=0.14m;

[0056] The length of the air supply hole l 1 =0.24m; width l 2 =0.02m;

[0057] The number of air supply holes on each side of the fresh air duct is n=15; the wind speed of the air supply holes is v=1.5m / s; d 0 =0.5m;

[0058] The layout of the air supply holes is symmetrical to the center along the fresh air duct, and the spacing increases from either end of the fresh air duct to the center, between the first air supply hole from the end and the N+1=8th air supply hole The lengths of the unopened part of the air duct side wall are: 0.478m, 0.957m, 1.435m, 1.913m, 2.391m, 2.870m, 3.348m, 3.826m.

Embodiment 3

[0060] The length of the pig house L=27m; the width of the pig house B=9.5m; the height from the ground to the highest point of the roof is H=3.3m, and the rated air volume of the fan is Q=0.95m 3 / s;

[0061] The length l=27m of the fresh air pipeline of air duct;

[0062] The length of the section of the fresh air duct a=0.33m; and the width b=0.21m;

[0063] The length of the air supply hole l 1 =0.36m; width l 2 =0.03m;

[0064] The number of air supply holes on each side of the fresh air duct is n=13; the wind speed of the air supply holes is v=1.8m / s; d 0 =0.5m;

[0065] The layout of the air supply holes is symmetrical to the center along the fresh air duct, and the spacing increases from either end of the fresh air duct to the center, between the first air supply hole from the end and the N+1=7th air supply hole The lengths of the unopened part of the air duct side wall are: 1.781m, 1.781m, 5.342m, 5.342m, 8.904m, 8.904m.

[0066] In actual construction, each di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com