Fish cream fermented soybean pulp and production method and application thereof

A technology of fermented soybean meal and production method, which is applied in the direction of application, animal feed, animal feed, etc., can solve the problems of high cost of spray drying, large amount of addition, and inability to be widely used, so as to reduce the disease of breeding animals, promote healthy growth, and benefit significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

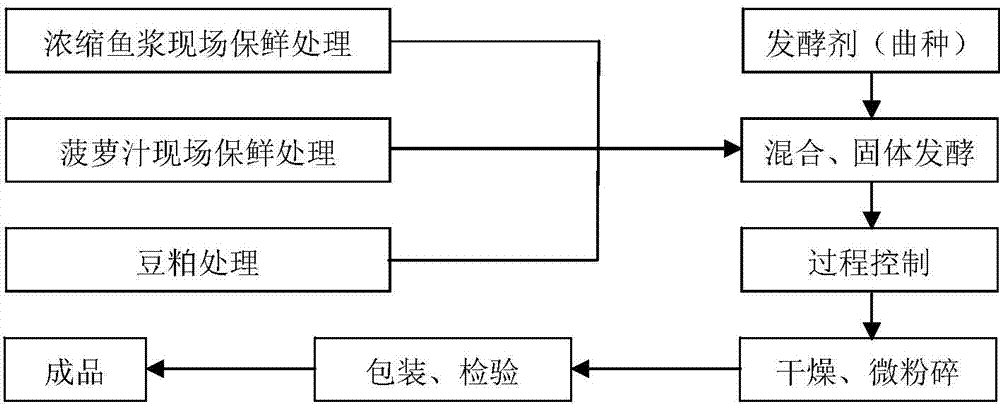

Method used

Image

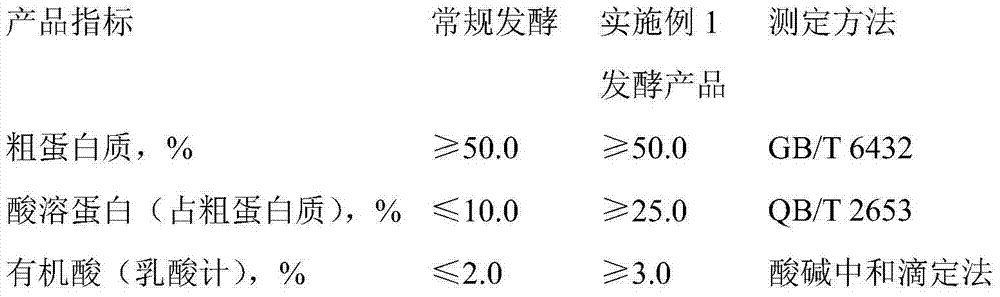

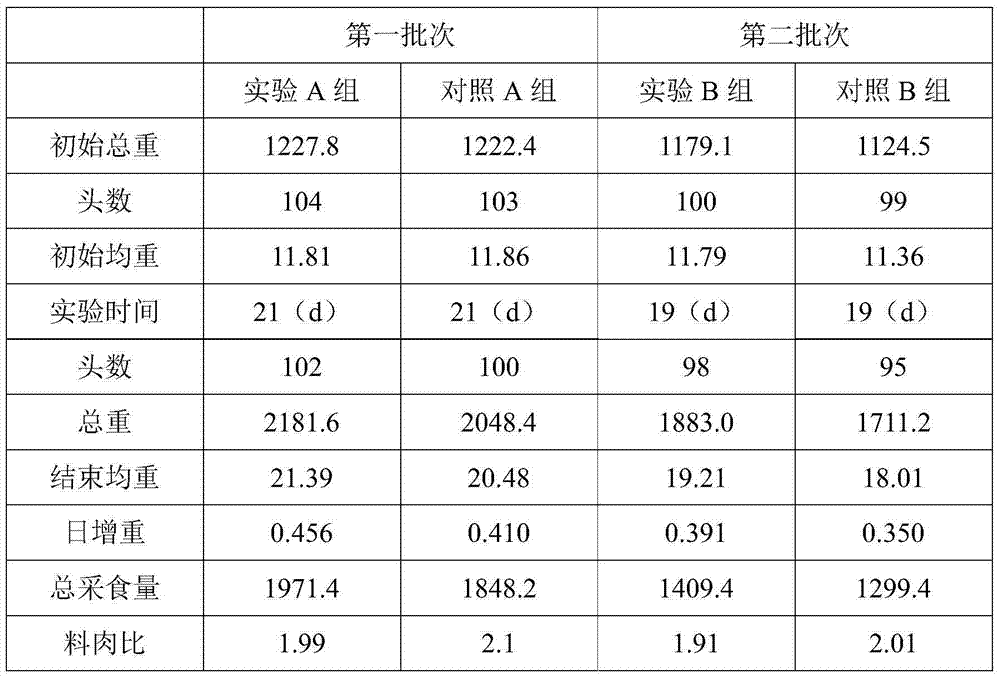

Examples

Embodiment 1

[0032] (1) Prepare soybean meal, concentrated fish soluble slurry with a moisture content of 65wt% after on-site fresh-keeping treatment, and pineapple juice through on-site fresh-keeping treatment. The concentrated fish soluble pulp is kept fresh at the production site of the fishmeal factory, and 5.5wt% of the weight of the concentrated fish soluble pulp is added with fermented soybean molasses and 1.5wt‰ koji seeds for fresh keeping treatment. The pineapple juice is kept fresh at the production site of the pineapple processing plant, and 12.5wt% fermented soybean molasses and 1.5wt‰ high-saccharomyces yeast are added as the weight of the pineapple juice to carry out the fresh-keeping treatment. The kind of koji used for the preservation of the concentrated fish soluble slurry is the same as that used in step (2).

[0033] (2) 350 kilograms of concentrated fish paste used per ton of soybean meal and 150 kilograms of pineapple juice used per ton of soybean meal were mixed, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com