Equipment and method for producing d-alpha-tocopheryl acetate

A technology of tocopherol acetate and equipment, applied in the field of producing d-α-tocopherol acetate, can solve problems such as harm to workers' health, high energy consumption, blockage of discharge ports, etc. The effect of protecting the health of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

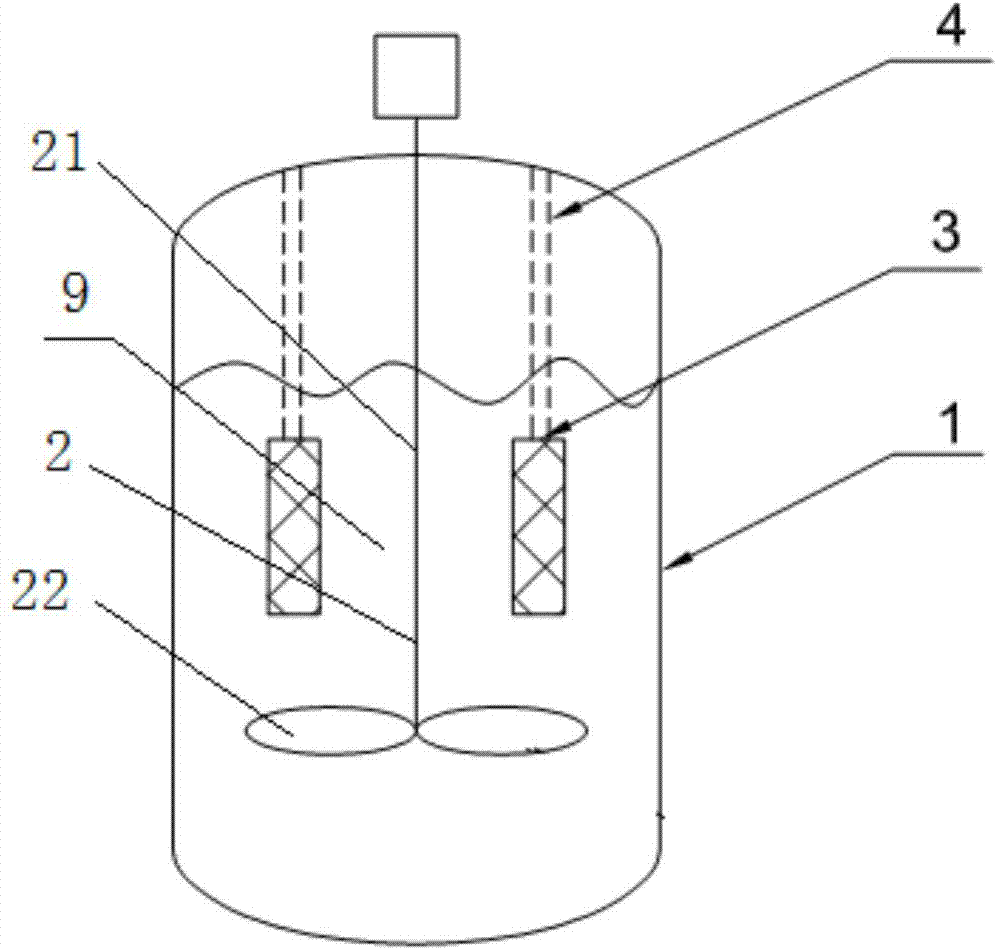

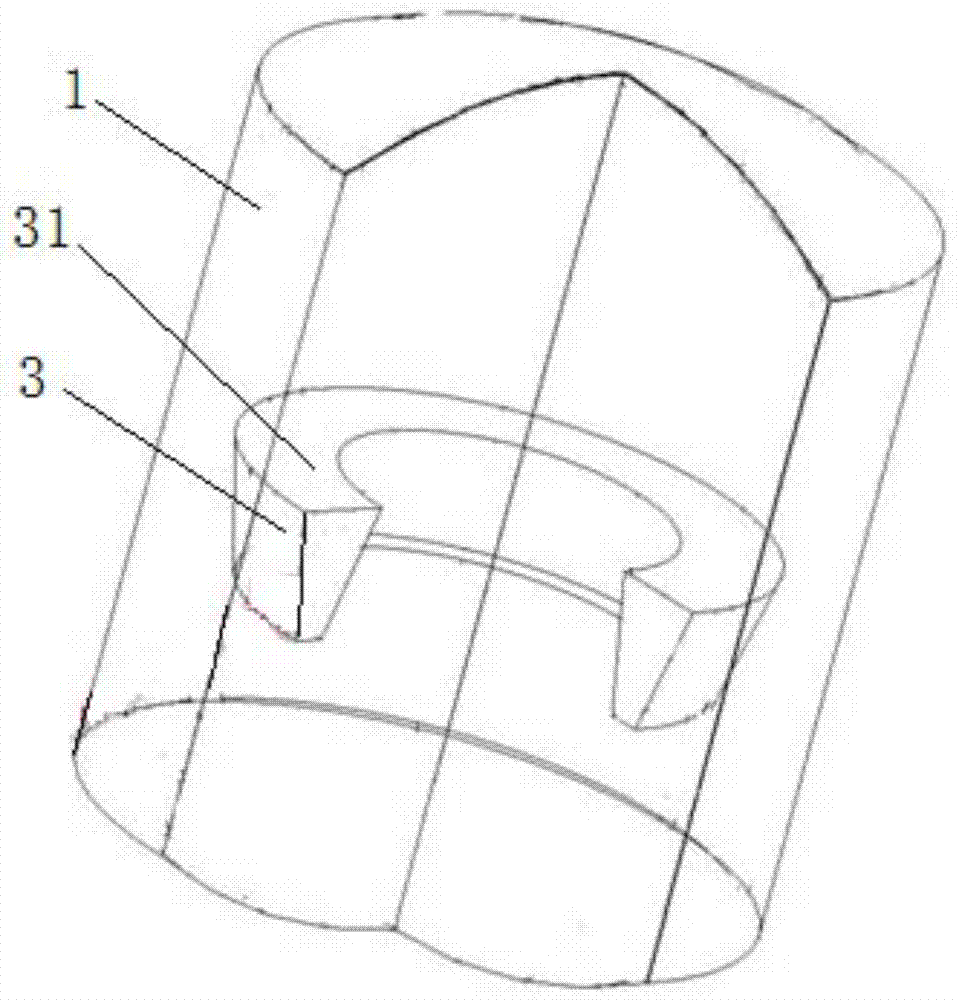

[0058] Such as figure 1 As shown, this embodiment provides a kind of equipment for producing d-alpha-tocopherol acetate, including a reactor 1 and an agitator 2 arranged in the reactor 1. In this embodiment, the reactor 1 is a batch type Reactor. In the reactor 1, the stirrer 2 stirs therein, so that the materials in the reactor 1 are mixed and heat transfered uniformly. In this embodiment, the equipment for producing d-α-tocopherol acetate also includes a box structure 3 arranged below the liquid level of the reaction solution in the reactor 1 and used for filling zinc powder. The body structure 3 is formed with a number of through holes with a diameter not larger than the minimum particle diameter of the zinc powder. Through the setting of the box structure 3, when feeding operation in the reactor 1, the zinc powder can be added first, and then acetic anhydride is added through the liquid feeding port on the reactor 1, thereby avoiding the Workers are exposed to acetic an...

Embodiment 2

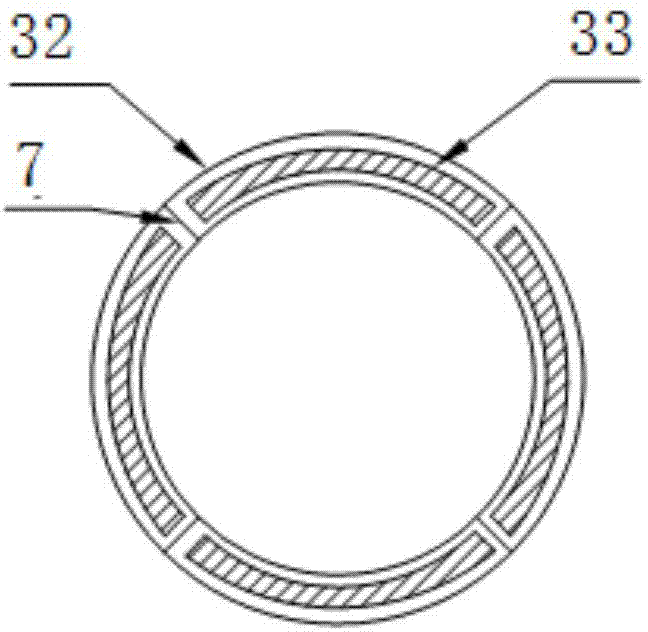

[0073] This embodiment provides a kind of equipment for producing d-alpha-tocopherol acetate, as a kind of alternative mode of the box structure described in embodiment 1, in this embodiment, such as Figure 5 and Figure 6 As shown, the box structure is a split structure. Specifically, in this embodiment, the box structure is a ring-shaped arrangement of four 1 / 4 ring structures, wherein the upper width of the box structure L=100mm, lower width L=80mm, the first through hole formed on the surface of the outer support layer 32 is a triangular hole with a side length of 8mm, and the material of the lining 33 is SS316L (316 stainless steel, international new brand 06Cr17Ni12Mo2), the said The through-holes formed on the surface of the inner liner 33 are circular holes, the diameter of the through-holes of the inner liner 33 is 300 mesh, the particle size of the zinc powder is 250 mesh, and the filling amount of the zinc powder is 14 days.

Embodiment 3

[0075] This embodiment provides a kind of equipment for producing d-alpha-tocopherol acetate, as a kind of alternative mode of the box structure described in embodiment 1, in this embodiment, such as Figure 7 and Figure 8 As shown, the box is a split structure, specifically, the box structure is four wedge-shaped structures arranged in a ring, wherein the upper width L=150mm of the box structure, and the lower width L=120mm , the first through-hole formed on the surface of the outer support layer 32 is a square hole with a side length of 5mm, the material of the inner lining 33 is polyvinyl chloride, and the through-hole formed on the surface of the inner lining 33 is square, The diameter of the through holes formed on the surface of the inner liner 33 is 400 mesh, and the particle diameter of the zinc powder is 300 mesh. In this embodiment, the filling amount of the zinc powder is 30 days, and the box structure 3 is fixed on the stirring shaft through a supporting structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com