Intermediate compound for chemical synthesis preparation of sanguinarine and preparation method thereof

A chemical synthesis and compound technology, applied in the direction of organic chemistry, can solve the problems of high irritation of intermediates, ineffective treatment of waste water, long reaction steps, etc., and achieve the effects of short synthesis route, improved labor safety and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method and synthesis route of the above intermediate compounds are as follows:

[0043]

[0044] Compound C is prepared from compound A and compound B by condensation reaction, which is the intermediate compound.

[0045] Preferably, the above preparation method specifically includes: compound a reacts with dichlorosulfoxide first, and then prepares compound C through condensation reaction with compound B; The condensation reaction is carried out under alkaline conditions.

[0046] Preferably, the alkaline condition is provided by an organic base or an inorganic base. Further, the organic base is selected from triethylamine, diisopropylamine, diisopropylethylamine, etc; The inorganic base is selected from sodium carbonate, sodium bicarbonate, sodium hydroxide, etc., the reaction solvent of the condensation reaction is selected from dichloromethane, ethyl acetate, toluene, chlorobenzene, etc., and the reaction temperature is - 10 ~ 110 ℃, preferably 0-40 ℃....

Embodiment 1

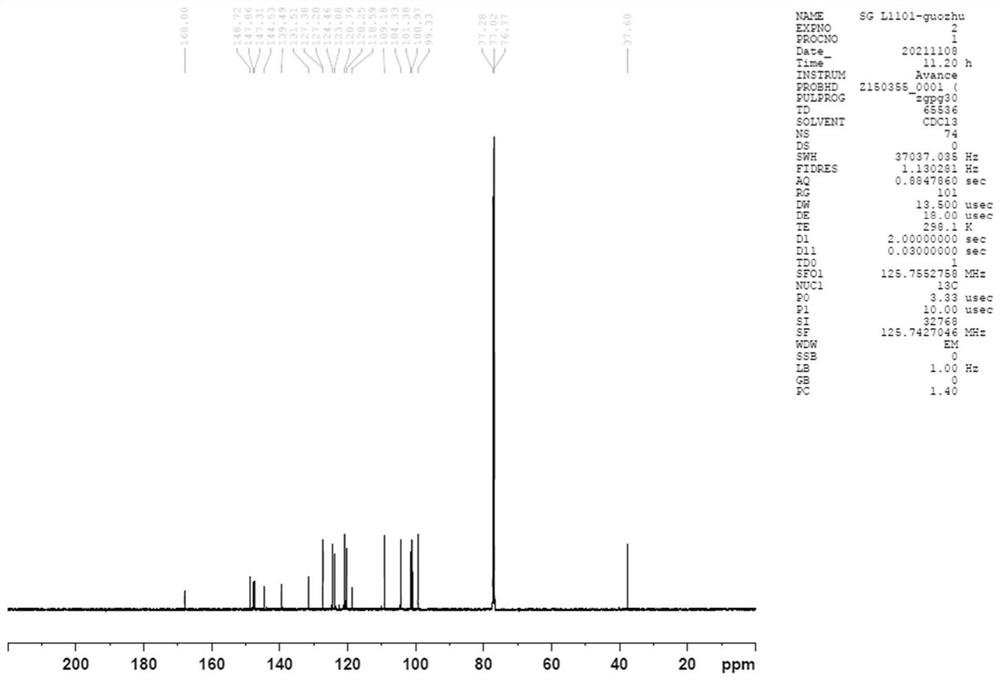

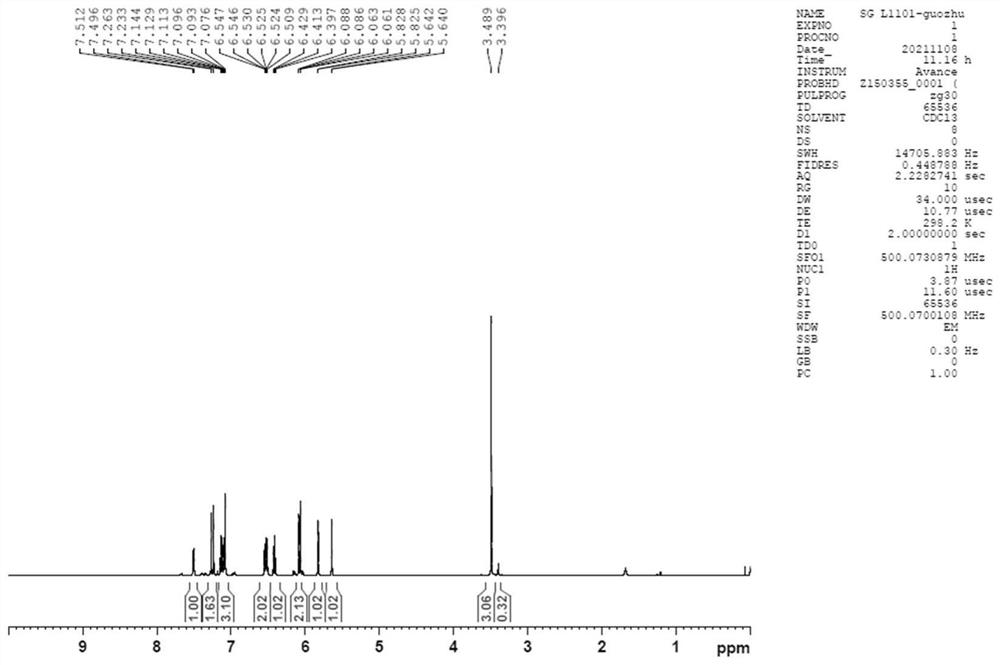

[0058] Example 1: preparation of compound I

[0059]

[0060] Add compound a (5g, 30mmol) and 20ml dichloromethane into reactor 1, add dichlorosulfoxide (3.94g, 33mmol) dropwise, increase temperature and reflux reaction, track TLC to no raw material residue, concentrate under reduced pressure to remove excess dichlorosulfoxide, and dilute with 40ml dichloromethane; Compound B (5.62g, 30mmol), 100ml dichloromethane and triethylamine (3.19g, 31.5mmol) were added into reactor 2. The reaction liquid in reactor 1 was added dropwise to reactor 2 at 0 ℃ and naturally rose to room temperature for reaction. TLC tracked that there was no raw material left, and 5% NaOH and 5% h were used successively 2 SO 4 , washed with saturated salt water, anhydrous Na 2 SO 4 After drying, dichloromethane was recrystallized to obtain 6G white solid, namely compound C, with a yield of 59.5% and a HPLC purity of 98.5%.

[0061] Compound C (5, 14.91mmol), 20mldmf, 60% sodium hydrogen (0.626g, 15.65mmol), M...

Embodiment 2

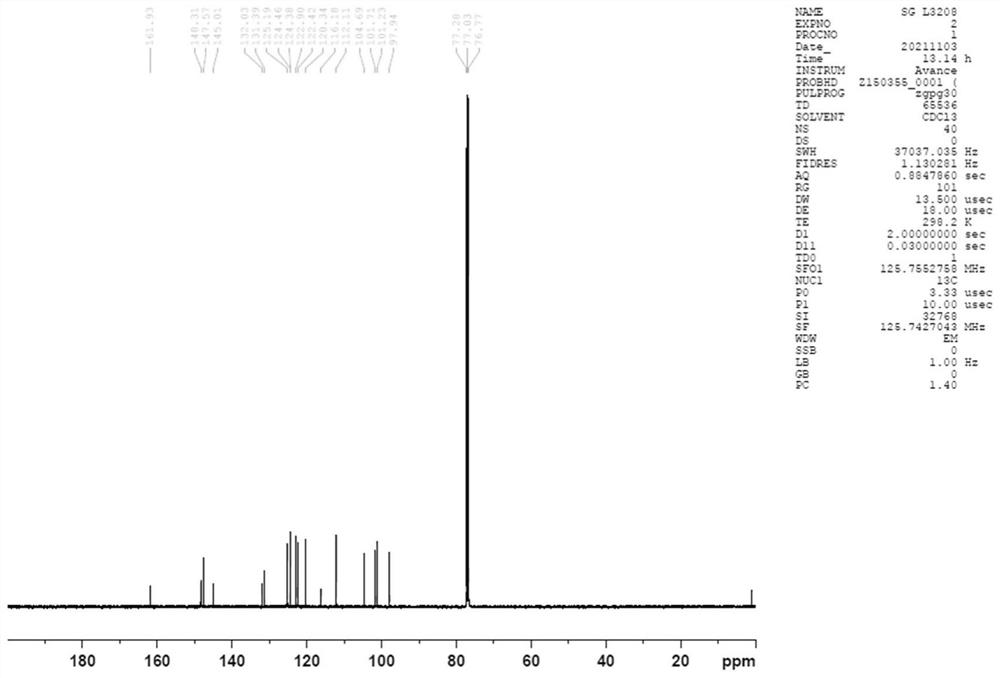

[0062] Example 2: preparation of compound I

[0063]

[0064] Add compound a (10g, 60mmol) and 40ml toluene into reactor 1, add dichlorosulfoxide (3.94g, 33mmol) dropwise, raise the temperature for 70 ℃ reaction, track TLC to no raw material residue, concentrate under reduced pressure to remove excess dichlorosulfoxide, and dilute 80ml toluene; Compound B (11.2g, 60mmol), 200ml toluene and diisopropyl ethylamine (8.14g, 63mmol) were added into reactor 2. The reaction solution in reactor 1 was added dropwise to reactor 2 at 0 ℃ and naturally rose to room temperature for reaction. TLC tracked that there was no raw material left, and 5% NaOH and 5% h were used successively 2 SO 4 , washed with saturated salt water, anhydrous Na 2 SO 4 After drying, dichloromethane was recrystallized to obtain 13g white solid, namely compound C, with a yield of 64.4% and a HPLC purity of 99.1%.

[0065] Compound C (10g, 29.8mmol), 40mlnmp, 60% sodium hydrogen (1.3g, 32.8mmol) were added to reactor 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com