Test structure for testing etching process, forming method thereof, and testing method

A technology for testing structures and testing methods, which is applied in the fields of technology for producing decorative surface effects, microstructure technology, microstructure devices, etc., and can solve the problems of inability to truly and reliably reflect the influence of etching processes, low accuracy, and test results. Poor reliability and other problems, to achieve the effect of simple and fast testing, reliability and accuracy improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] It can be seen from the background art that the testing method provided by the prior art has poor reliability and low accuracy, and cannot truly and reliably reflect the influence of the etching process on the MEMS device.

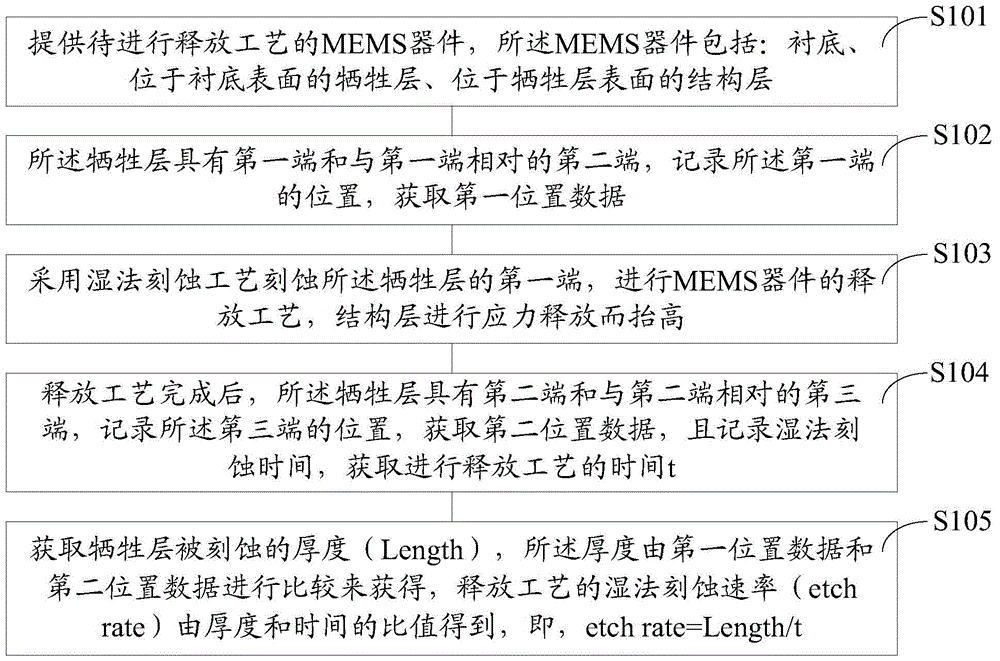

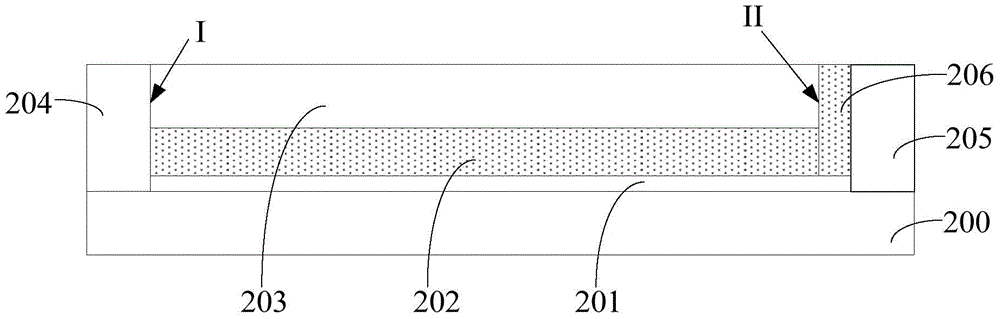

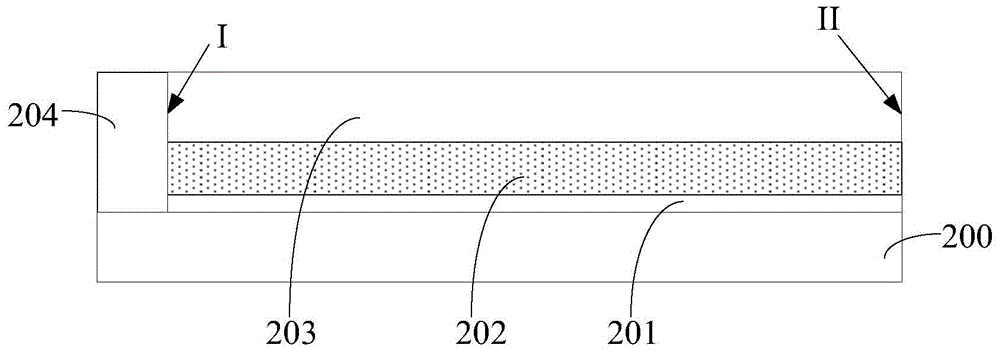

[0041] Please refer to figure 1 , figure 1 It is a schematic flow chart of a test method: step S101, providing a MEMS device to be released, and the MEMS device includes: a substrate, a sacrificial layer on the surface of the substrate, and a structural layer on the surface of the sacrificial layer; step S102, the The sacrificial layer has a first end and a second end opposite to the first end, the position of the first end is recorded, and the first position data is obtained; step S103, etching the second end of the sacrificial layer by a wet etching process At one end, the release process of the MEMS device is performed, and the structural layer is lifted by stress release; step S104, after the release process is completed, the sacrificial layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com