Heat transfer type resistance box

A resistance box and heat transfer technology, which is applied in heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as unstable plasma equipment, affecting grid voltage stability, grid voltage fluctuations, etc., to achieve Avoid excessive current impact, save power, and avoid aging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

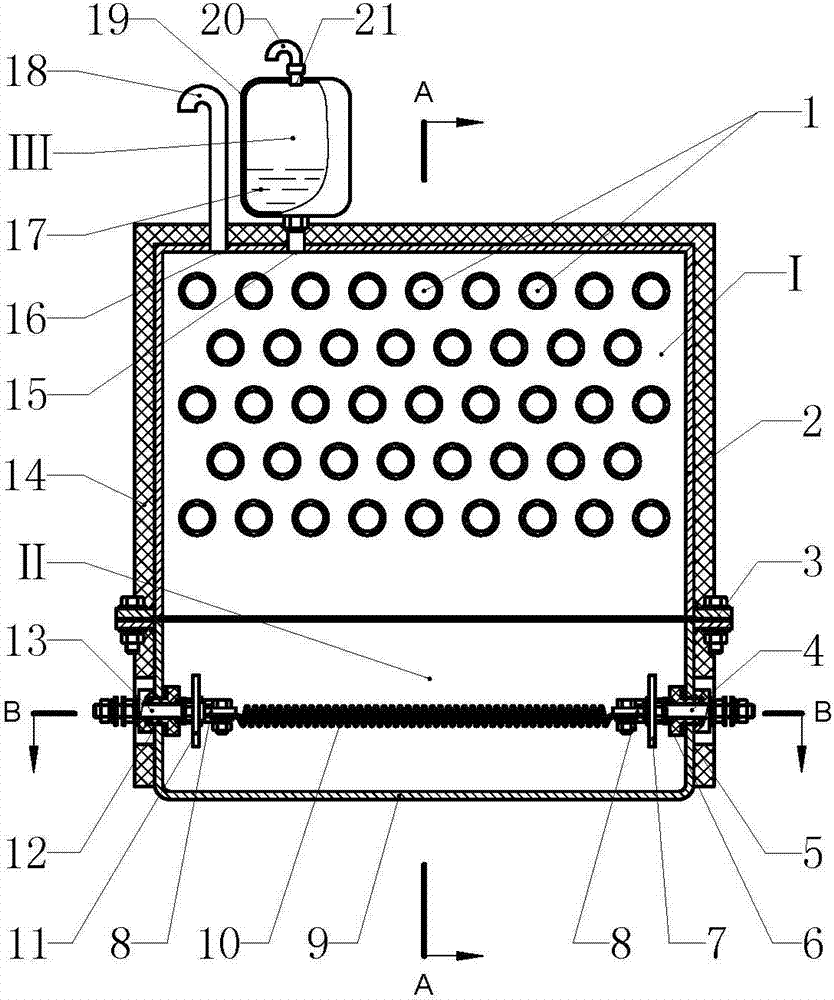

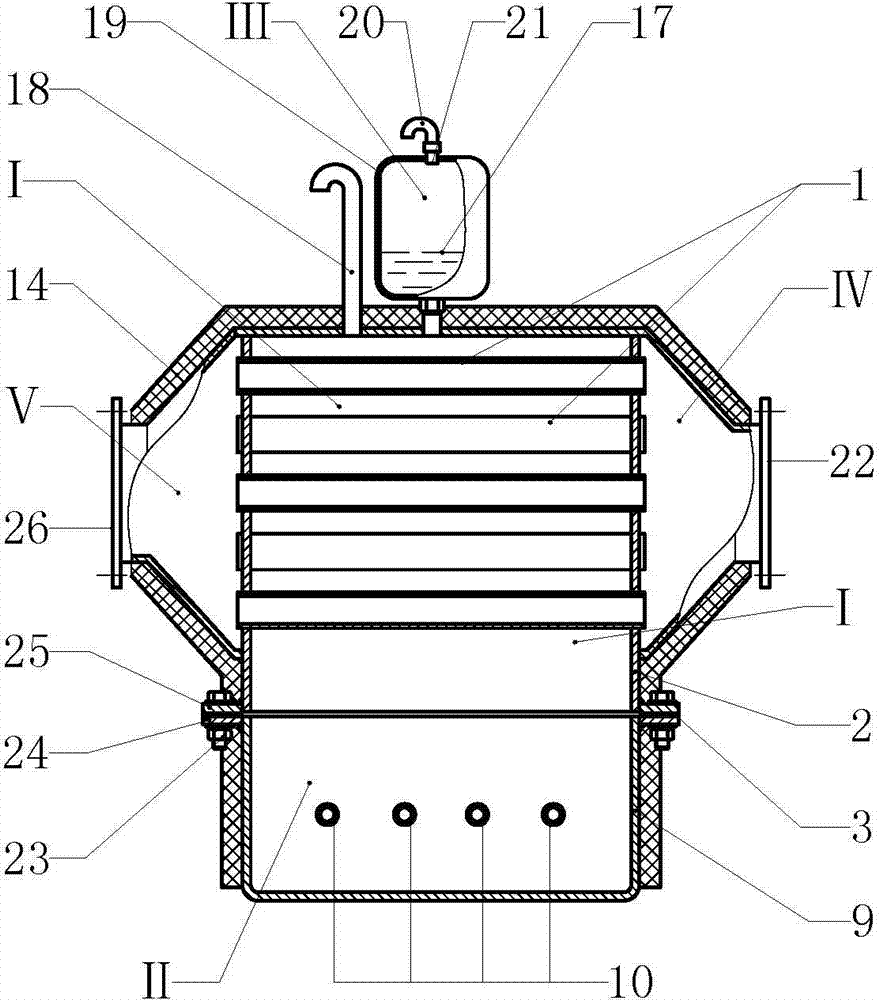

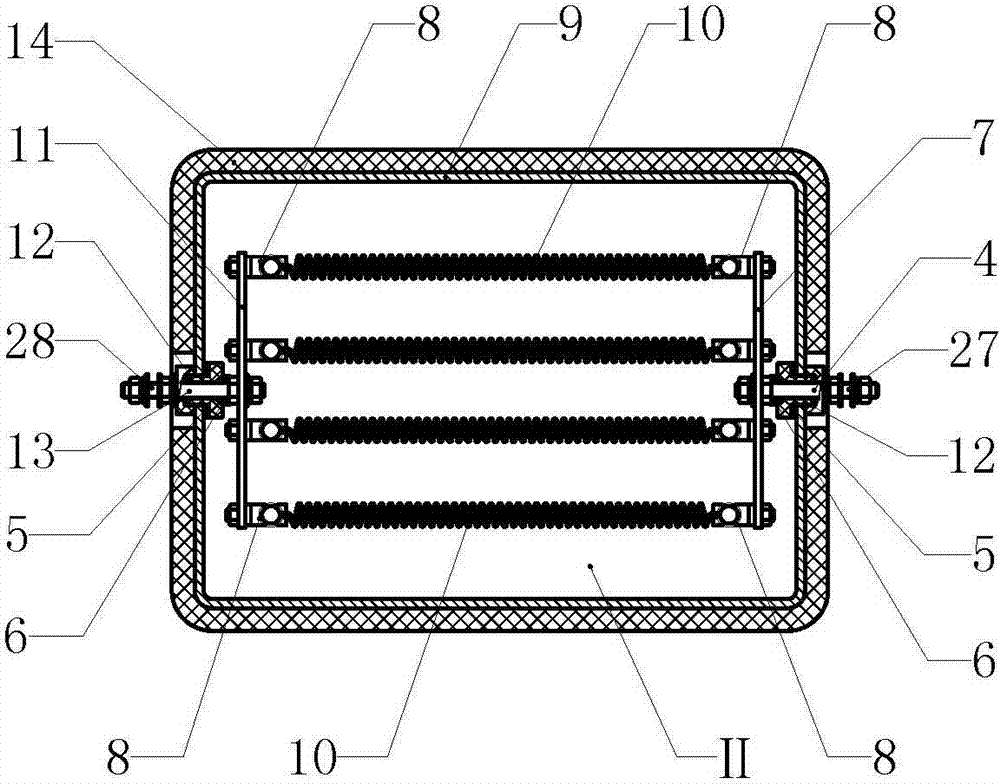

[0016] Example 1 figure 1In the embodiment shown, the heat transfer resistance box consists of an upper box (2), an air duct array (1), a lower box (9), a resistance wire (10), an incoming line assembly (13) and an outgoing line assembly ( 4) Composition, wherein the upper box (2) communicates with the lower box (9), the inner space of the upper box (2) constitutes the heat exchange area (I), and the air duct array (1) is arranged in the heat exchange area ( In Ⅰ), the air duct array (1) is formed by arranging multiple air ducts, and the two ends of each air duct pass through the walls on both sides of the upper box (2). The front air chamber (Ⅴ) has the rear air chamber (IV) on the right side of the upper box (2), and the front air chamber (Ⅴ) is connected to the rear air chamber (Ⅳ) through the space inside the duct array (1), The front air chamber (Ⅴ) is connected to the air inlet interface (26), and the rear air chamber (Ⅳ) is connected to the air outlet interface (22); t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com