Carbon fiber reinforced aluminum alloy conductor cable

A technology of aluminum alloy conductor and carbon fiber, which is applied in the direction of metal/alloy conductors, conductors, insulated cables, etc., can solve the problems that the temperature rise cannot be monitored, the cable tensile strength is not enough, and the cable is damaged, etc., to achieve a comprehensive communication solution, Excellent material selection, reduce the effect of line loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

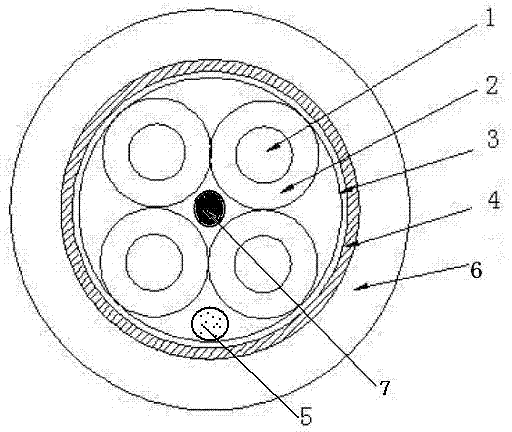

[0013] Such as figure 1 As shown, in the carbon fiber reinforced aluminum alloy conductor cable, a single-core insulated wire core composed of a cross-linked polyethylene insulation layer 2 is extruded on the aluminum alloy conductor 1, and then four insulated wire cores are twisted to form a cable. Core, the inner lining layer 3 of ceramic fiber tape is wrapped around the cable core, the interlocking armor layer 4 is wrapped on the inner lining layer 3, and then the outer jacket layer of halogen-free, low-smoke and environmentally friendly polyolefin is extruded on the armor layer 4 6.

[0014] A carbon fiber reinforced core 7 is provided in the gap in the center of the wire core. The carbon fiber reinforced core 7 includes carbon fiber filaments and ceramic fiber filaments. The stranded carbon fiber filaments and ceramic fiber filaments are twisted and then impregnated with resin. It is cured in an oven. In this embodiment, there is one carbon fiber thread and six ceramic fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com