Carbon fiber reinforced self-temperature-measurement composite cable with aluminum alloy conductors

A technology of aluminum alloy conductors and composite cables, which is applied in the direction of metal/alloy conductors, conductors, insulated cables, etc., can solve the problems of insufficient tensile strength of cables, failure to monitor temperature rise, and affect cable information transmission, etc., to reduce installation costs , Reduce the threat of accidents, improve the effect of transmission capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

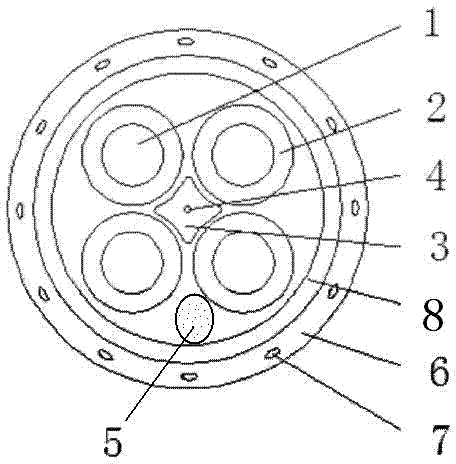

[0015] Such as figure 1 As shown, a carbon fiber-reinforced aluminum alloy conductor self-temperature-measuring composite cable includes several conductors 1, the outer sides of several conductors 1 are respectively wrapped with insulating layers 2, and the several conductors 1 wrapped with insulating layers 2 are provided with The elastic body 3, the elastic body 3 can isolate the conductor and relieve the external extrusion force at the same time, the cross section of the elastic body 3 is a quadrilateral with four sides concaved into an arc.

[0016] The inner side of the elastomer 3 is provided with a carbon fiber reinforced core 4, the carbon fiber reinforced core 4 includes carbon fiber filaments and ceramic fiber filaments, which are formed by twisting the strands of carbon fiber filaments and ceramic fiber filaments, impregnating them with resin, and then curing them in an oven. In this embodiment, there is one carbon fiber filament, and six ceramic fiber filaments.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com