NEA electron source for vertically emitting AlGaAs/GaAs nanowires

A technology of vertical emission and electron source, applied in the direction of photoemission cathode, circuit, discharge tube, etc., to achieve the effect of high vertical emission efficiency at the top, sufficient photon absorption, and suppression of side photoemission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

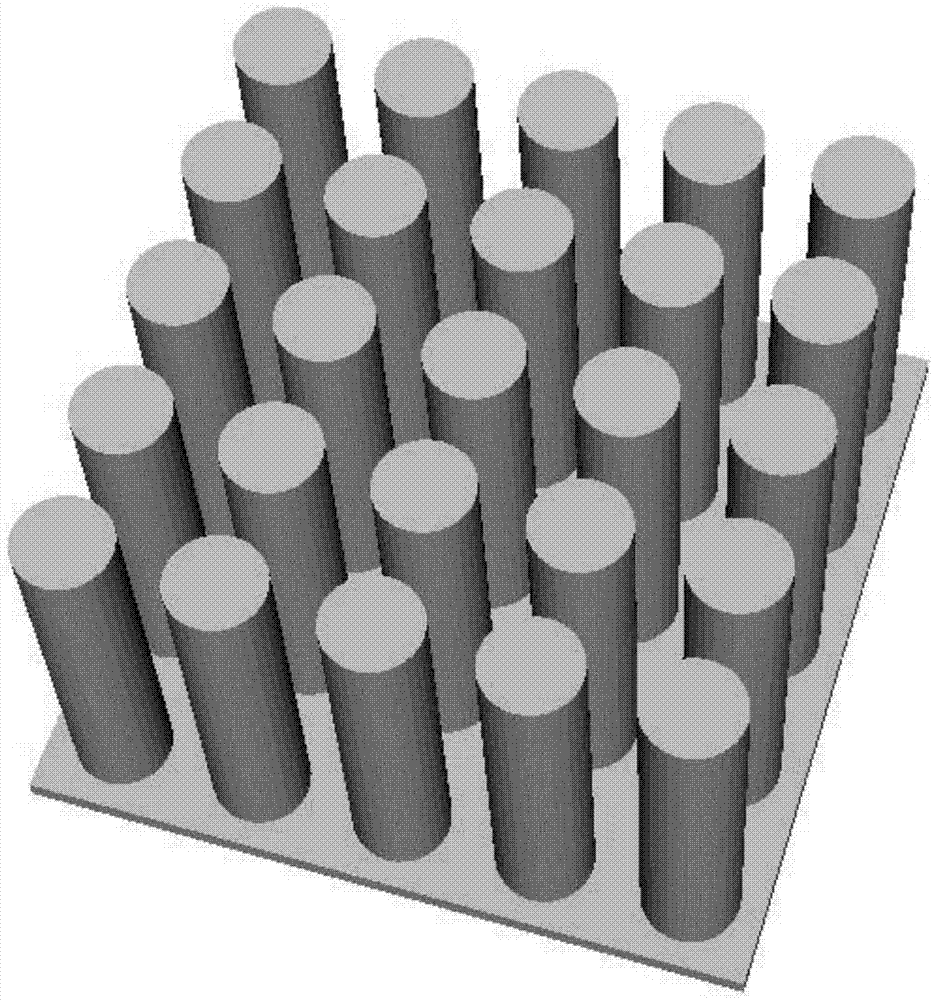

[0037] see figure 1 A kind of NEA electron source that vertically emits AlGaAs / GaAs nanowires. The variable bandgap AlGaAs / GaAs nanowire arrays are arranged periodically and neatly. When light is incident, the light is continuously absorbed in the variable bandgap AlGaAs / GaAs nanowire arrays. , reflection, and refraction until most of the light is absorbed, since the variable bandgap AlGaAs / GaAs nanowires have a built-in electric field along the vertical direction, most of the photoelectrons drift to the top of the nanowires under the action of the built-in electric field, and finally from The top GaAs emitter layer emits into vacuum, enabling vertical photoemission.

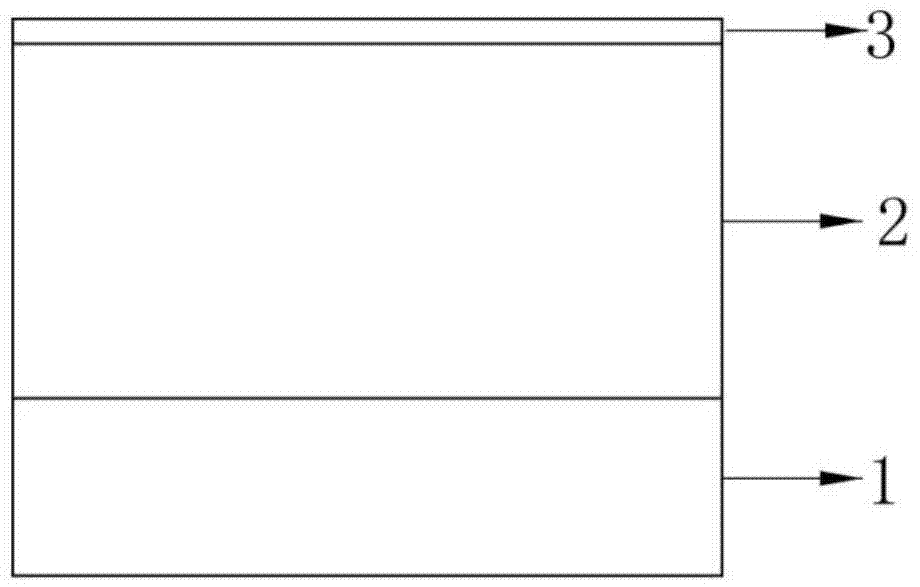

[0038] A method for preparing a NEA electron source for vertically emitting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com