Static Random Access Memory (SRAM) unit forming method

A patterning and fin technology, applied in electrical components, transistors, electrical solid devices, etc., can solve the problems of low signal transmission speed and poor performance, and achieve improved signal transmission speed, good performance, and strong signal transmission capabilities. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

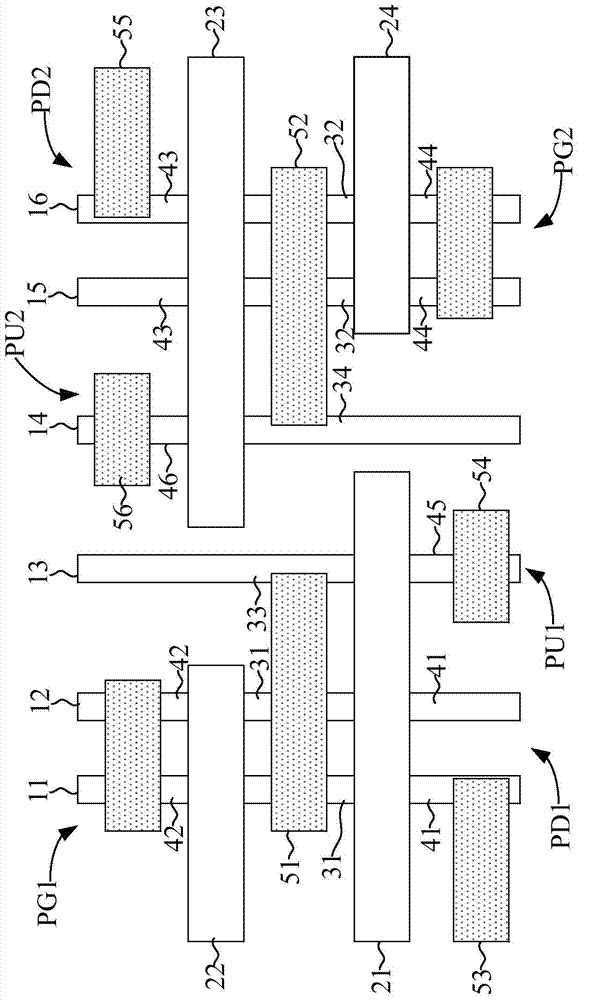

[0059] Aiming at the problems existing in the prior art, it is found through analysis: refer to figure 1 , the first metal layer 51 and the second metal layer 52 are formed in the same patterning step. Specifically, the method for forming the first metal layer 51 and the second metal layer 52 includes: first, forming a photoresist layer on the interlayer dielectric layer;

[0060] Expose the photoresist layer. During the exposure process, the bright area of the mask corresponds to the position of the first metal layer and the second metal layer, and the photoresist layer corresponding to the bright area is exposed; then developing, the exposed photoresist layer partially removed;

[0061] Next, the patterned photoresist layer is used as a mask to etch the interlayer dielectric layer with a partial thickness to form the first groove and the second groove, and then the patterned photoresist layer is removed. Thereafter, a first metal layer is formed in the first trench and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com