Memristor and manufacturing method thereof

A technology of memristor and bottom electrode, which is applied in the field of non-volatile memory, can solve the problems of incomplete research on material system, unclear mechanism, and short research time of memristor, and achieve low cost, low operating voltage, The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

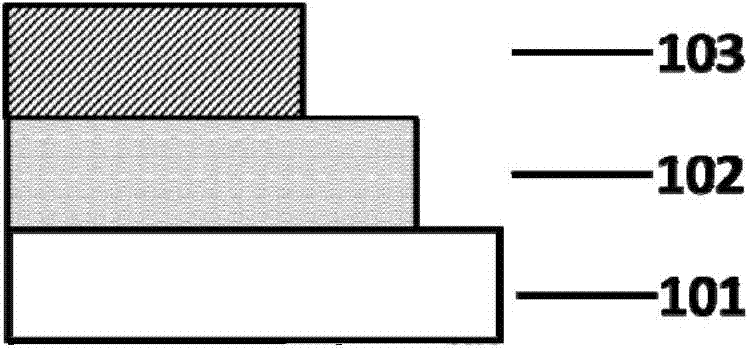

[0032] figure 1 It is a structural schematic diagram of the memristor of the vertical structure of the present invention, such as figure 1 As shown, the bottom of the structure is the substrate 101, the substrate 101 is used to support the structure of the entire memristor, and the substrate is used as the bottom electrode; a layer of single crystal cerium oxide film 102 is epitaxy on the substrate 101, Finally, a top electrode 103 is deposited on the cerium oxide film 102 .

[0033] The process flow of the preparation method of the memristor of the vertical structure of the present invention includes the following specific steps:

[0034] 1) Substrate cleaning, the substrate is Nb-doped SrTiO 3 , the substrate not only plays the role of making the whole device, but also serves as the bottom electrode.

[0035] 2) Laser Molecular Beam Epitaxy on Nb-doped SrTiO 3 (NSTO) Epitaxial CeO 2 Thin film, before deposition, the vacuum degree of the chamber is ~1×10 -7 Pa; during t...

Embodiment 2

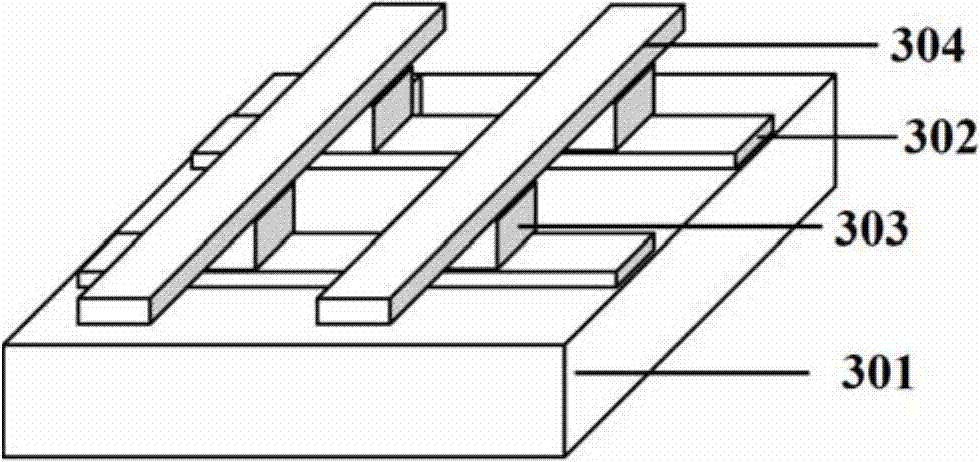

[0040] In this embodiment, the memristor is a cross-array structure, such as image 3 shown. The bottom end of the structure is the substrate 301, which is used as the bottom electrode in addition to supporting the entire memristor structure; the bottom electrode 302 (bit line) of the cross array is etched on the substrate 301; Epitaxial CeO on 302 2 Thin film 303; on CeO 2A top electrode 304 is deposited on top of the film. Such as Figure 4 , 5 Shown, its preparation process is specifically:

[0041] Step 401 (corresponding to 501): select heavily doped single crystal silicon (111) as a substrate, and clean it.

[0042] Step 402 (corresponding to 502): using reactive ion etching technology (reactive gas is CF 3 Br) directly forming a bottom electrode on the substrate;

[0043] Step 403 (corresponding to 503): using laser molecular beam epitaxy to epitaxially grow (111) crystal orientation CeO 2 The thin film is used as the material of the resistive switching functio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com