Dimethyl sulfide preparation method

A technology of dimethyl sulfide and methanol, applied in the field of preparation of dimethyl sulfide, can solve the problems of low methanol conversion rate and the like, and achieve the effects of stable skeleton structure, suitable acid center structure and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The invention provides a method for preparing dimethyl sulfide, which comprises reacting hydrogen sulfide and methanol in the presence of a catalyst to synthesize dimethyl sulfide, wherein the catalyst contains molecular sieves with an MFI structure.

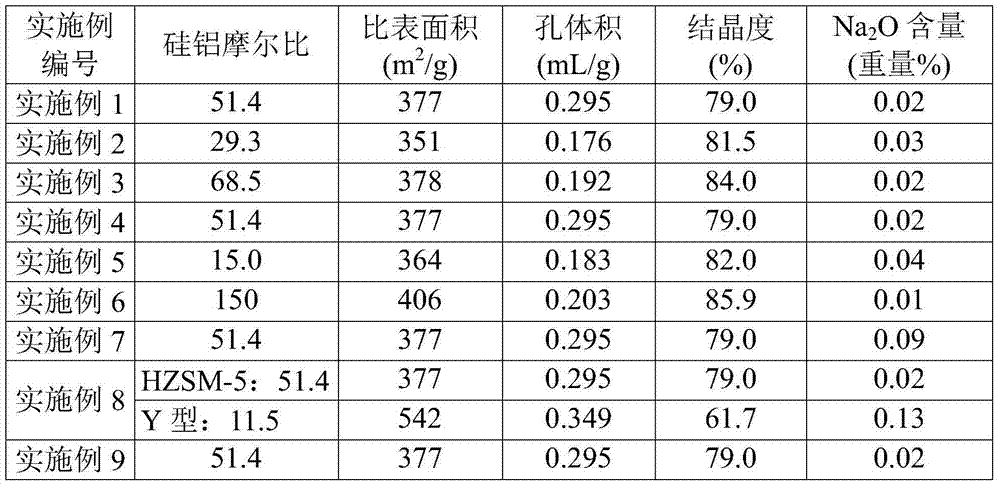

[0017] According to the present invention, the molar ratio of silicon to aluminum of the molecular sieve of the MFI structure (in terms of oxides, refers to SiO 2 / Al 2 o 3 , the same below) can be selected in a wide range. Preferably, in terms of oxides, the molecular sieve with the MFI structure has a molar ratio of silicon to aluminum of greater than 12 and less than or equal to 200; preferably in terms of oxides, the molecular sieve with the MFI structure has a molar ratio of silicon to aluminum of 15-150; More preferably, the molecular sieve with MFI structure has a molar ratio of silicon to aluminum of 20-70 in terms of oxides. When the molecular sieve with the MFI structure has the above-mentioned preferred sili...

Embodiment 1

[0034] This embodiment is used to illustrate the preparation method of dimethyl sulfide of the present invention.

[0035] HZSM-5 molecular sieves (performance parameters are shown in Table 1) were steam-treated at 300°C for 10 hours, then pressed into tablets, sieved, and 20-40 mesh particles were taken and packed in a tubular reaction tube with a diameter of 0.8 cm and a length of 55 cm. , the catalyst particle bed volume is 2.0 cm 3 .

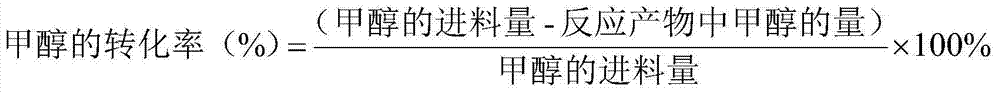

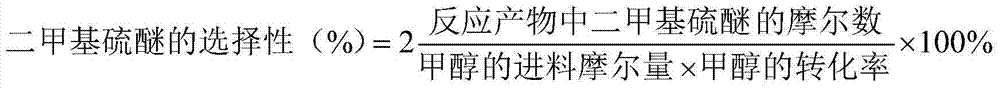

[0036] The reaction temperature is 300°C, the reaction pressure is 1atm, the feed molar ratio of hydrogen sulfide and methanol is 1:2, and the total gas volume space velocity is 1500h -1 Under the conditions of , the catalytic reaction for the preparation of dimethyl sulfide was carried out. The product obtained after the catalytic reaction was analyzed by gas chromatography for 3 hours, and the conversion rate of methanol and the selectivity of dimethyl sulfide were calculated according to the analysis results. The calculation results ar...

Embodiment 2

[0038] This embodiment is used to illustrate the preparation method of dimethyl sulfide of the present invention.

[0039] HZSM-5 molecular sieves (performance parameters are shown in Table 1) were steam-treated at 200°C for 6 hours, then pressed into tablets, sieved, and 20-40 mesh particles were taken and packed in a tubular reaction tube with a diameter of 0.8 cm and a length of 55 cm. , the catalyst particle bed volume is 2.0 cm 3 .

[0040] The reaction temperature is 270°C, the reaction pressure is 5atm, the feed molar ratio of hydrogen sulfide and methanol is 1:2.1, and the total gas volume space velocity is 725h -1 Under the conditions of , the catalytic reaction for the preparation of dimethyl sulfide was carried out. The product obtained after the catalytic reaction was analyzed by gas chromatography for 3 hours, and the conversion rate of methanol and the selectivity of dimethyl sulfide were calculated according to the analysis results. The calculation results ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com