Fuel oil additive

An additive and fuel technology, applied in the field of fuel additives, can solve the problems of rust on the inner wall of the fuel tank, low efficiency, damage to fuel system components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

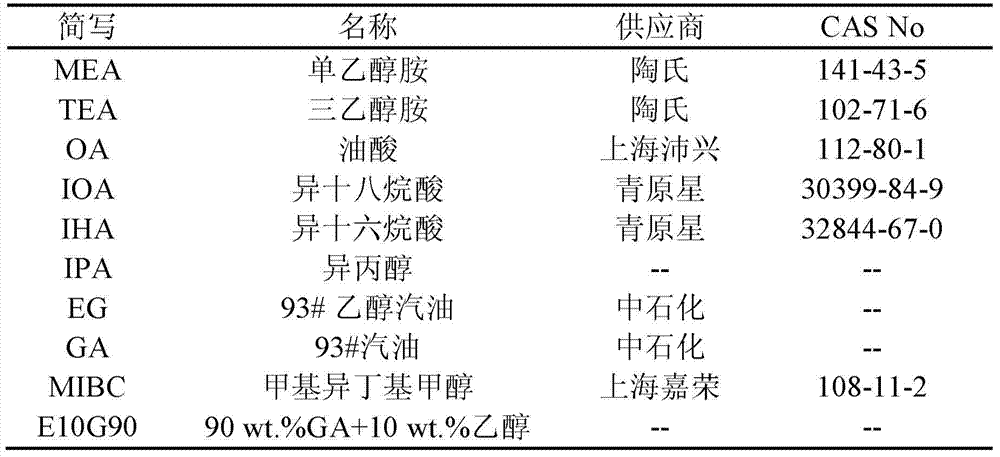

Method used

Image

Examples

Embodiment 1

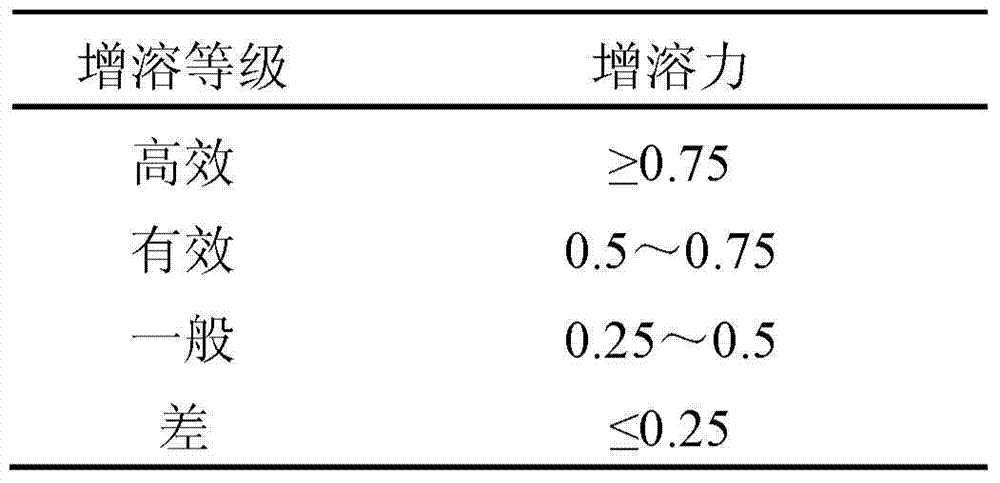

[0068] Prepare fuel additive sample 1 and sample 2 according to the composition shown in Table 5, and measure the solubilization performance of these samples according to the test method for solubilization performance, and the results are listed in Table 5.

[0069] table 5

[0070]

[0071] As can be seen from Table 5, the sample 1 that adopts IOA and the sample 2 that adopts IHA all have good solubilizing properties.

Embodiment 2

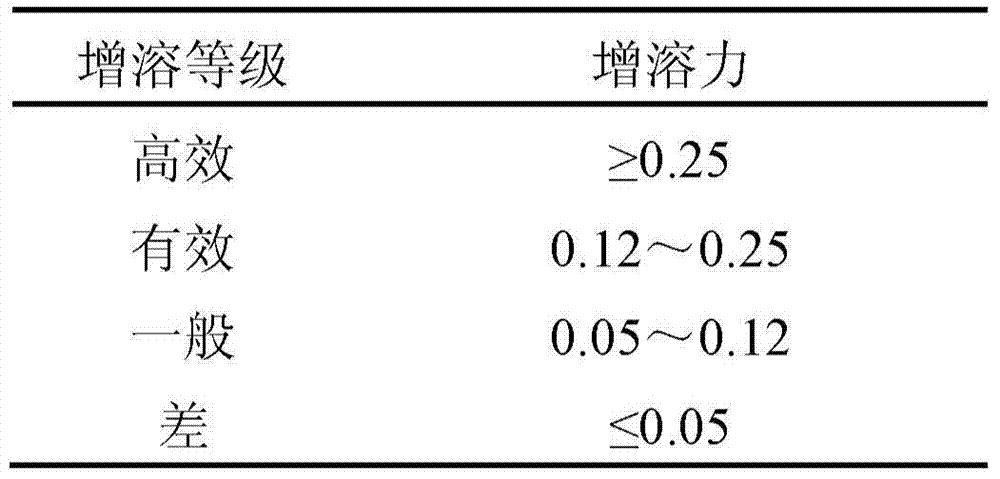

[0073] Prepare fuel additive sample 1 and samples 3-9 according to the composition shown in Table 6, and measure the solubilization performance of these samples according to the test method for solubilization performance, and the results are listed in Table 6.

[0074] Table 6

[0075]

[0076] It can be seen from Table 6 that sample 1 and samples 3-9 all have good solubilizing properties. It is worth noting that when the content of emulsifier IOA is low (sample 3, 4 and 6), the solubilization performance evaluation results of these samples to EG and E10G90 are "effective", and the solubilization performance evaluation results to GA (At this time, the overall evaluation result of the solubilization performance of these samples is still "effective"), this is because when the content of emulsifier is low, the solubilization effect of the samples on the water in the fuel is relatively weak. Weak, so, the content of emulsifier in the fuel additive provided by the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com