Fatty acid-based extractant for heavy metal ions as well as preparation method of extractant and extraction method of heavy metal ions

A technology for heavy metal ions and fatty acids, applied in separation methods, solvent extraction, chemical instruments and methods, etc., can solve problems such as difficulty in large-scale operation, large viscosity of ionic liquid, affecting efficiency, etc. Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Add 1.4mL of 2mol / L NaOH solution to 5mL (about 0.028mol) heptanoic acid, which contains 0.0028mol of NaOH, that is, the molar ratio of nonanoic acid to NaOH is about 10:1, and shake to form a mixed solution; the mixed solution is added to 10mL contains 0.12mol / L copper ion (Cu 2+ ) in the aqueous solution, adjust the pH of the water phase to 6.0, and stir vigorously; 2+ That is, it is removed, and the removal rate is 99.60%.

Embodiment 2

[0047] Add 2.4mL of 2mol / L NaOH solution to 5mL (about 0.032mol) of octanoic acid, which contains 0.0048mol of NaOH, that is, the molar ratio of octanoic acid to NaOH is about 10:1.5, and shake to form a mixed solution; this mixed solution is added to 20mL containing 0.10mol / L mercury ion (Hg 2+ ) in the aqueous solution, adjust the pH of the water phase to be 6.0, stir vigorously; let stand to separate the liquid, and the Hg in the waste water 2+ That is to be removed, the removal rate is 95.34%.

Embodiment 3

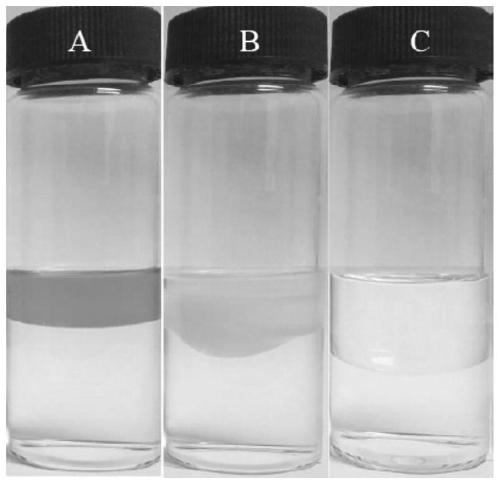

[0049] Add 5.0mL of 2mol / L NaOH solution to 5mL (about 0.034mol) of heptanoic acid, which contains 0.010mol of NaOH, that is, the molar ratio of heptanoic acid to NaOH is about 10:3, and shake to form a mixed solution; add the mixed solution respectively to volumes of 10mL containing nickel ions (Ni 2+ ), lead ions (Pb 2+ ), silver ions (Ag + ), cadmium ions (Cd 2+ ) in the aqueous solution, the metal ion concentration is 0.4mol / L, 0.4mol / L, 0.8mol / L, 0.4mol / L respectively, after mixing, the pH of the water phase is adjusted to 7.0, 5.5, 5.5, 6.0 respectively, vigorously stirred, static After separating the liquid, the metal ions are recovered and removed, and the removal rates are 98.28%, 94.58%, 95.54%, and 98.57%, respectively. In this example, with Ni 2+ 、Ag + 、Cd 2+ Formed phase-separated samples such as figure 1 As shown, it can be seen that heptanoate binds metal ions (Ni 2+ 、Ag + 、Cd 2+ ) was extracted into the upper oil phase by heptanoic acid to form a visc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com