Nutritional beer with green tea taste and brewing method thereof

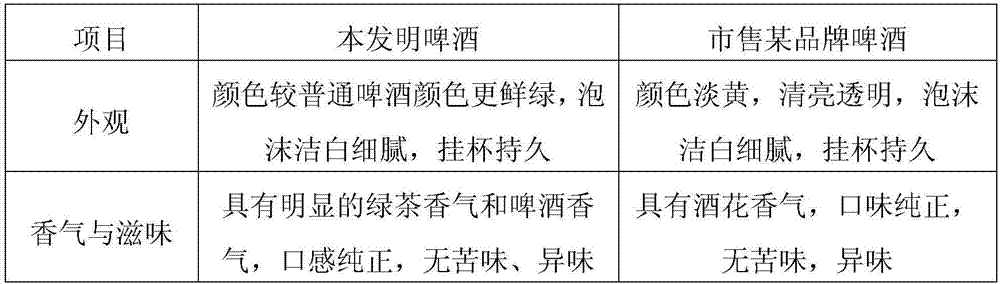

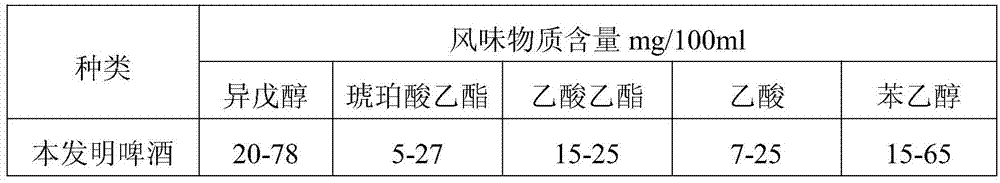

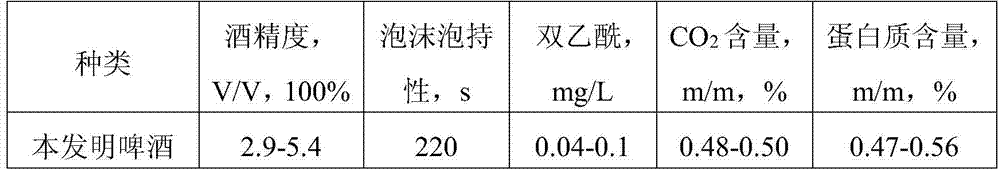

A taste and nutrition technology, applied in beer brewing and other directions, can solve the problems of inability to meet market demand, single taste, high alcohol content, and achieve the effects of low cost, simple process and fine foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of green tea powder: put the fresh tea leaves in a drying oven at 35-40° C. and dry them and then pulverize them to 200 meshes;

[0035] (2) Decolorization and deodorization treatment of alfalfa leaf protein: mix the two according to the ratio of 6 milliliters of absolute ethanol and 1 gram of alfalfa leaf protein, extract for 4 hours at a temperature of 85 ° C, and the extraction stage is 3 grade, to get alfalfa leaf protein; the 3 grades of extraction grades are specifically to pour out the extract after the first extraction, and then add absolute ethanol according to the ratio of every 6 milliliters of absolute ethanol and 1 gram of alfalfa leaf protein, Repeat 3 times to get alfalfa leaf protein;

[0036] (3) Gelatinization: 45 parts of rice flour, 5 parts of raw gypsum, and 150 parts of water are mixed for gelatinization;

[0037] (4) Saccharification: After adding 35 parts of barley malt powder, 6 parts of phosphoric acid and 150 parts of water to...

Embodiment 2

[0049] (1) Preparation of green tea powder: put the fresh tea leaves in a drying oven at 35-40° C. and dry them and then pulverize them to 200 meshes;

[0050] (2) Decolorization and deodorization treatment of alfalfa leaf protein: mix the two according to the ratio of 6 milliliters of absolute ethanol and 1 gram of alfalfa leaf protein, extract for 4 hours at a temperature of 85 ° C, and the extraction stage is 3 grade, to get alfalfa leaf protein; the 3 grades of extraction grades are specifically to pour out the extract after the first extraction, and then add absolute ethanol according to the ratio of every 6 milliliters of absolute ethanol and 1 gram of alfalfa leaf protein, Repeat 3 times to get alfalfa leaf protein;

[0051] (3) Gelatinization: 35 parts of rice flour, 10 parts of raw gypsum, and 200 parts of water are mixed for gelatinization;

[0052] (4) Saccharification: After adding 45 parts of barley malt powder, 10 parts of phosphoric acid and 120 parts of water ...

Embodiment 3

[0064] (1) Preparation of green tea powder: put the fresh tea leaves in a drying oven at 35-40° C. and dry them and then pulverize them to 200 meshes;

[0065] (2) Decolorization and deodorization treatment of alfalfa leaf protein: mix the two according to the ratio of 6 milliliters of absolute ethanol and 1 gram of alfalfa leaf protein, extract for 4 hours at a temperature of 85 ° C, and the extraction stage is 3 grade, to get alfalfa leaf protein; the 3 grades of extraction grades are specifically to pour out the extract after the first extraction, and then add absolute ethanol according to the ratio of every 6 milliliters of absolute ethanol and 1 gram of alfalfa leaf protein, Repeat 3 times to get alfalfa leaf protein;

[0066] (3) Gelatinization: 40 parts of rice flour, 8 parts of raw gypsum, and 180 parts of water are mixed for gelatinization;

[0067] (4) Saccharification: After adding 40 parts of barley malt powder, 8 parts of phosphoric acid and 130 parts of water to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com