Quick splicing platform with LED lamps

An LED light and fast technology, applied in the platform field, can solve the problems of slow assembly and disassembly, inconvenient cleaning, easy damage, etc., and achieve the effect of reducing weight, facilitating diversion and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

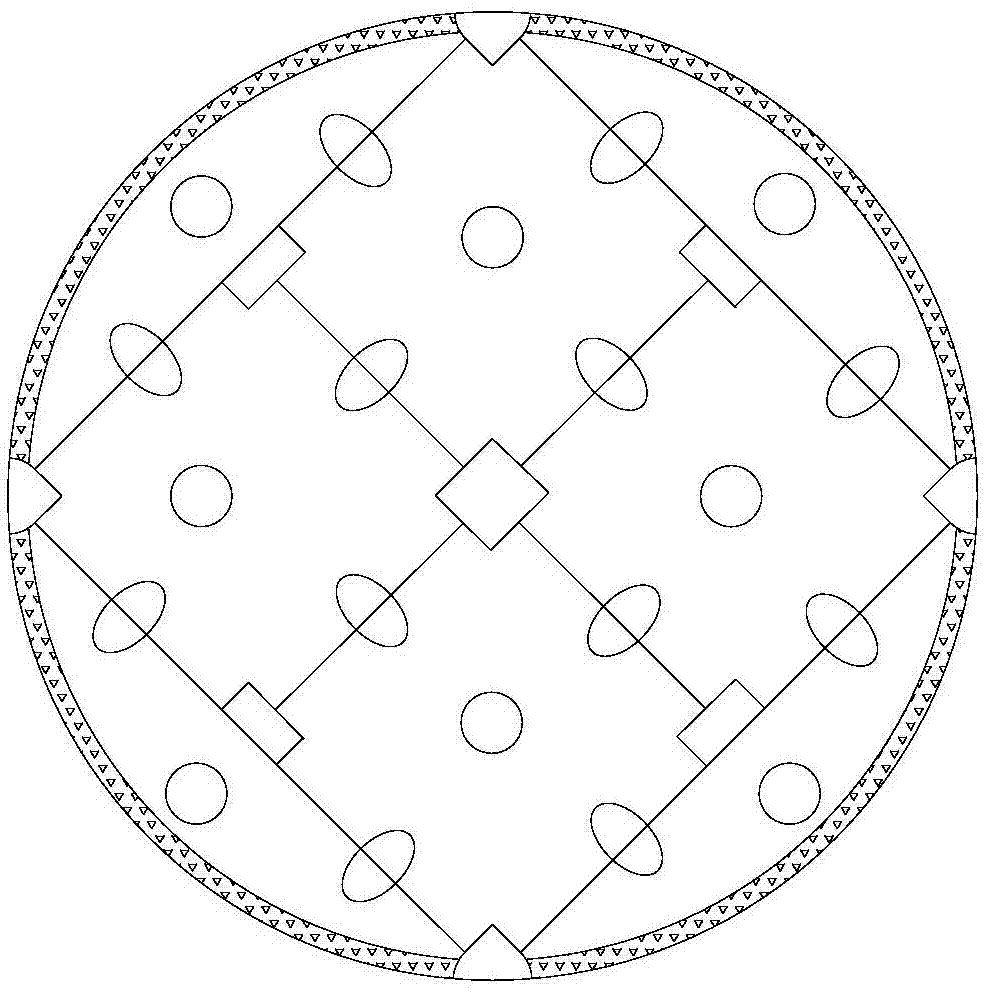

[0031] Such as figure 1 and figure 2 As shown, the rapid assembly platform with LED lights of the present invention includes 4 square splicing plates and 4 bow-shaped splicing plates;

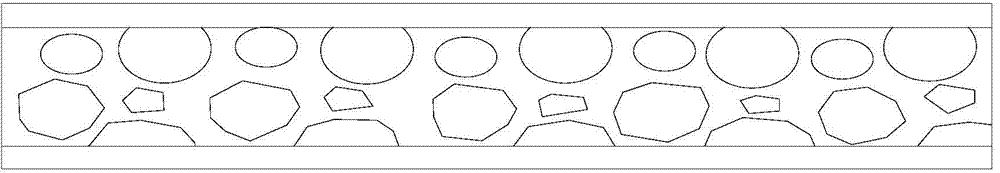

[0032] The materials of the 4 square splicing plates and the 4 bow-shaped splicing plates are flexible molecular materials, and steel plates are covered on the top, bottom and side walls of the square splicing plates and the bow-shaped splicing plates;

[0033] Square splicing panels and bow splicing panels are composite structural panels composed of two layers of aluminum panels and honeycomb material filled in the middle;

[0034] There are side bolt holes on the groove frame of each side of each square splicing plate and each bow splicing plate, and bolt installation holes are provided at the side bolt holes on the corresponding composite structure plate for installing the side ends bolt;

[0035] The four corners of each square splicing plate and the two corners of each bow-shaped splic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com