A pile-forming method based on recycled aggregate piles from construction waste

A technology of construction waste and recycled aggregate, applied in construction, sheet pile walls, foundation structure engineering, etc., can solve the problems of rapid increase, surface uplift, construction noise, structural damage, etc., and achieve good shear and compression resistance , Construction vibration is small, good balance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

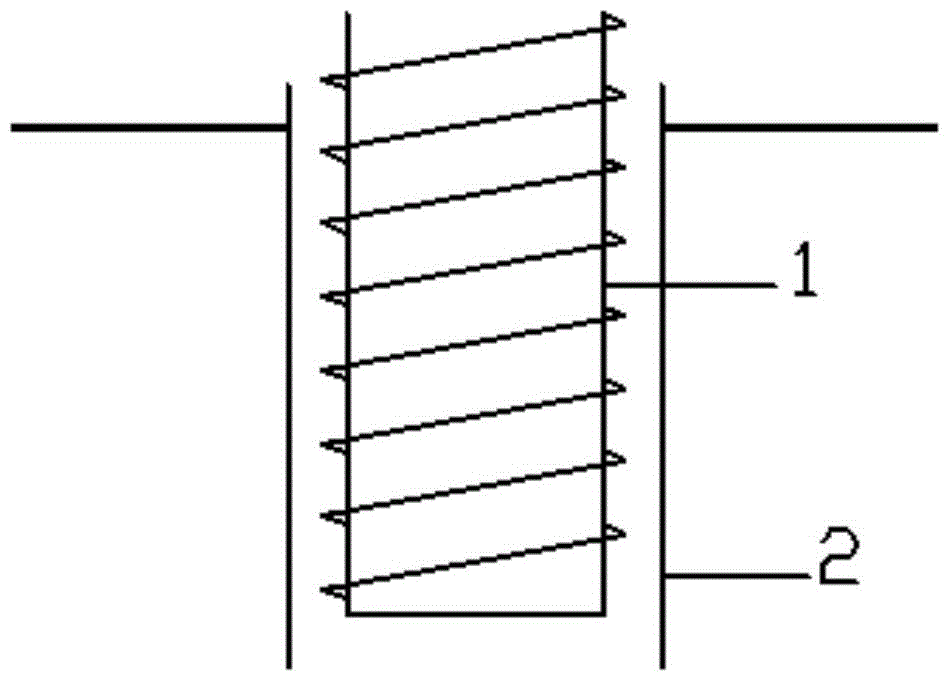

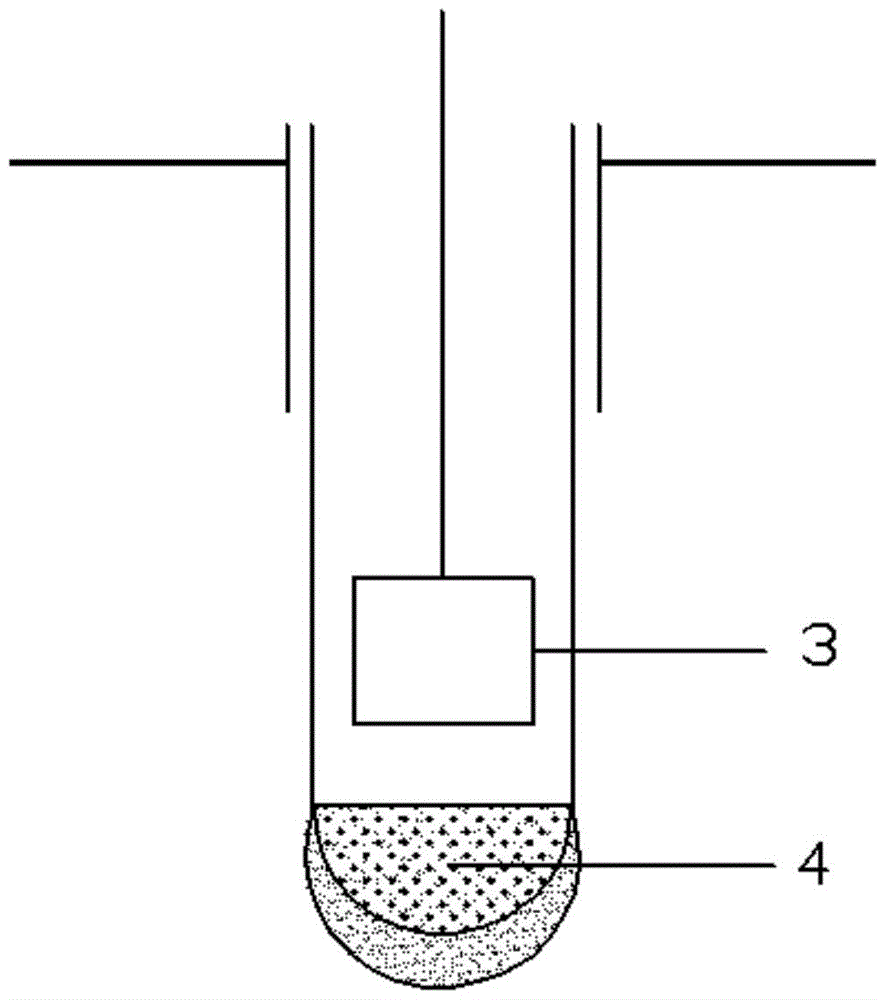

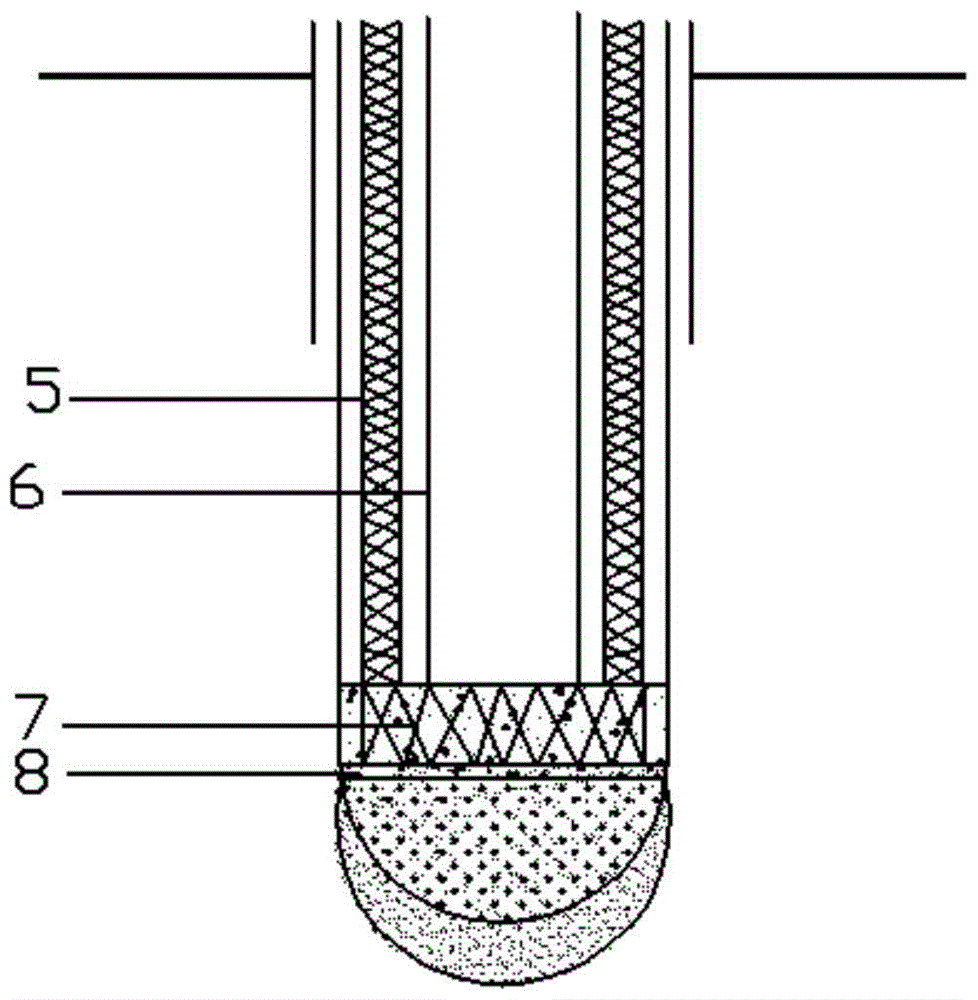

Method used

Image

Examples

Embodiment 1

[0042] The pre-construction area of an industrial park is 20,000m 2 Building workshop, single-story light steel structure. The geological conditions are: 15m-18m below the natural ground is silt, the characteristic value of foundation soil bearing capacity fak=42KPa, Es=1.46MPa; the bearing layer is silt, the characteristic value of foundation bearing capacity fak=192KPa, Es=10.38MPa. Design The characteristic value of the bearing capacity of the foundation soil below the pad is required to be fak=110KPa.

[0043] The original plan was to set up concrete caps of 4*4 meters, and set four prestressed pipe piles with a diameter of 580mm under each cap, and the length of the piles was 28m. The caps were equipped with primary and secondary beams and a 160mm thick reinforced concrete floor.

[0044]Using this scheme, based on the pile-forming method of construction waste recycled aggregate piles, a pile based on construction waste recycled aggregates is formed. The length of the...

Embodiment 2

[0065] In a certain area, a bridge with a total length of 76 meters and 8 piers was pre-built. The original design was mechanical piling. Use this scheme instead, and form piles based on construction waste recycled aggregate piles based on the pile-forming method of construction waste recycled aggregate piles.

[0066] The pretreatment of construction waste is the same as in Example 1.

[0067] The steps of the pile-forming method using construction waste as recycled aggregate are the same as in Example 1.

[0068] After the construction was completed, 10 test piles were drilled successively, 6 of which were subjected to load tests, which proved that the bearing capacity, concrete strength and actual pile diameter of the piles all met the design standards.

[0069] After adopting the spiral cast-in-situ pile of this scheme, the cost is reduced by 26%, and after using the spiral cast-in-situ pile of this scheme, the cost is reduced by 26%, and the cost of the lower structure i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com