3D printing system for building engineering construction and positioning method of 3D printing system

A 3D printing and construction engineering technology, applied in the fields of architecture, building structure, building material processing, etc., can solve the problems of large area, complex assembly, difficult to add printing, etc., to reduce the floor space and reduce the cost of use , mobile flexible and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

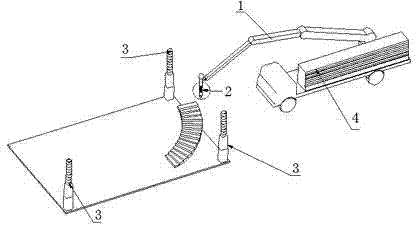

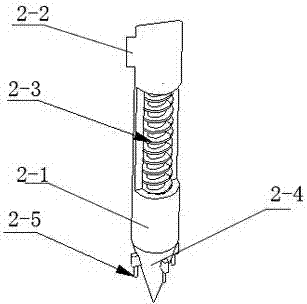

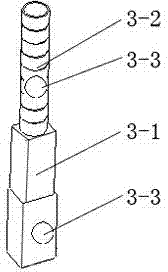

[0029] A kind of construction engineering construction 3D printing system provided by this embodiment, such as figure 1 As shown, it includes a multi-joint manipulator 1, a 3D printer printing extrusion head device 2, an ECU control unit, and at least three positioning rods 3 that are not in a straight line around the construction site. The handheld end of the multi-joint manipulator 1 is installed with a 3D printer printing extrusion The head device 2, the 3D printer printing extrusion head device 2 is equipped with a signal transceiver 2-5, and the positioning rod 3 is equipped with at least three positioning sources, the signal receiver is connected to the positioning source, and the signal of the positioning rod is transmitted The end is connected to the transceiver end of the ECU control unit, the driving end of the ECU control unit is connected to the controlled end of the multi-joint manipulator 1, and the ECU control unit contains:

[0030] The standard building device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com