Method for improving magnetic property of sintered neodymium-iron-boron permanent magnet

A permanent magnet and NdFeB technology, which is applied in the field of improving the magnetic properties of sintered NdFeB permanent magnets, can solve the problem that the Nd-rich phase cannot form magnetic isolation, the thin layer of the Nd-rich phase is not uniform and continuous, and the main phase grains of the magnet are weak. Sharp corners and other problems can be solved, and the effects of good application prospects, microstructure optimization, remanence and maximum energy product improvement can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

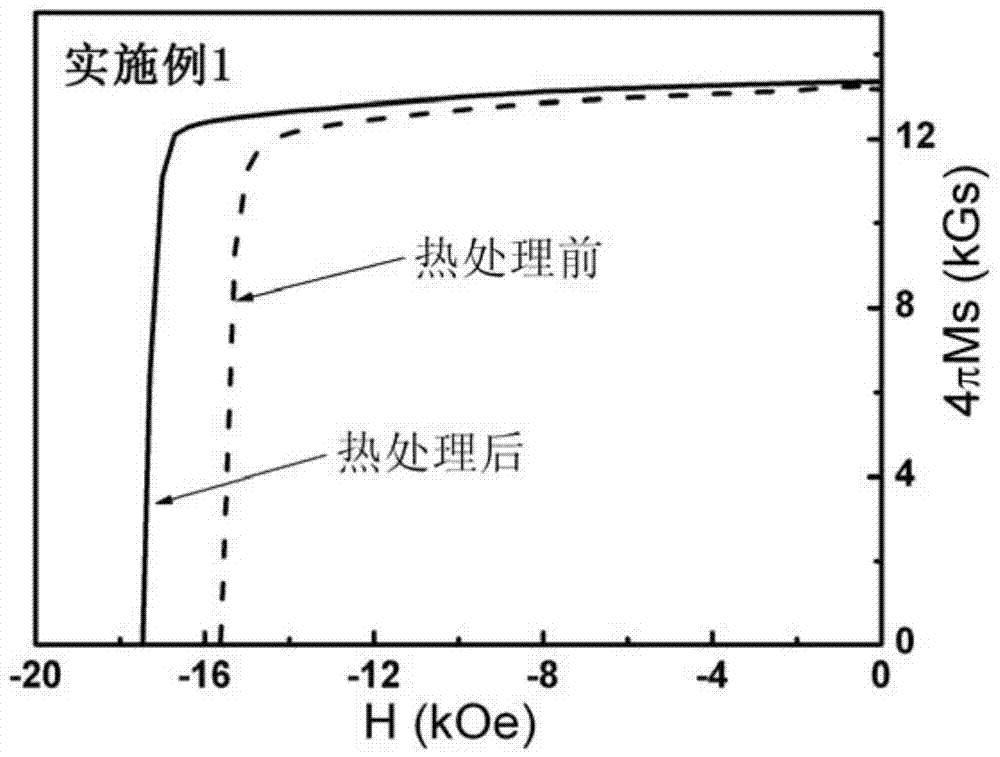

Embodiment 1

[0026] In this embodiment, induction heating is used to improve the magnetic properties of sintered NdFeB magnets, and the specific process steps are:

[0027] 1) Process the Nd-Fe-B magnet after high-temperature sintering and tempering at 500°C for 2 hours into a cylindrical shape. The diameter of the cylinder is about 10mm, and the height is about 10mm. The surface is polished with sandpaper and cleaned.

[0028] 2) Test the magnetic properties of the magnet after step 1) using the NIM-500C permanent magnet material high temperature measurement system at room temperature, and obtain the demagnetization curve of the magnet before induction heating treatment, see figure 1 . The magnetic performance parameters are shown in Table 1.

[0029] 3) Put the magnet tested in step 2) into the quartz crucible of the vacuum induction furnace, and evacuate the furnace chamber so that the air pressure is as low as 1.4×10 -2 Pa, then pass Ar gas to clean the furnace cavity twice, and the...

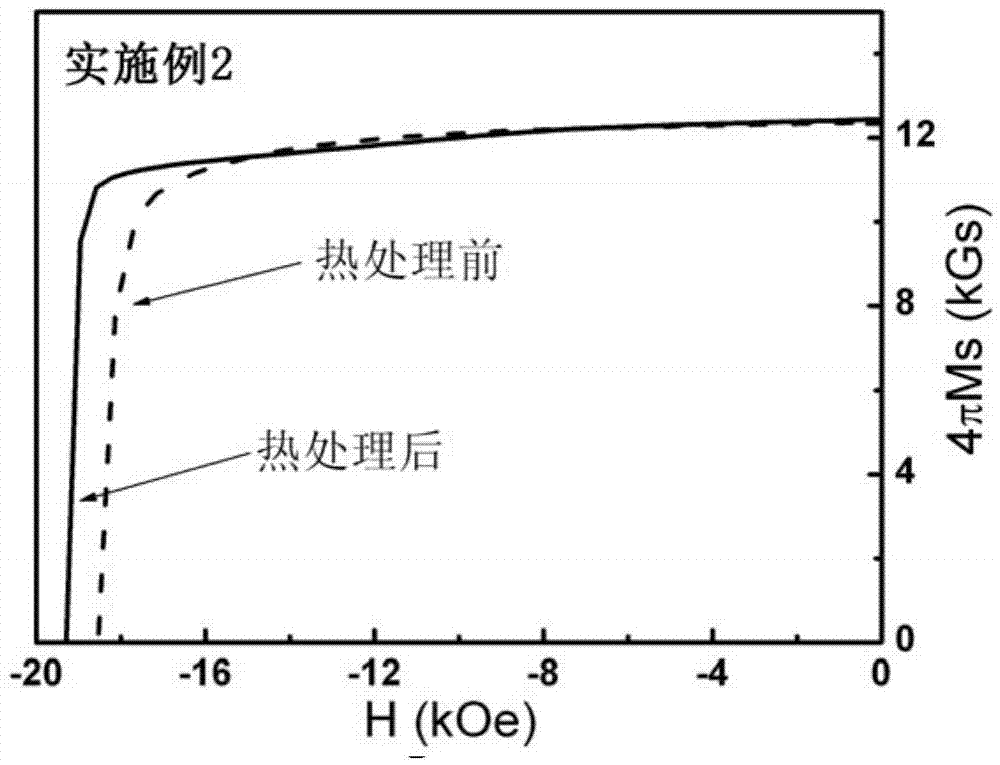

Embodiment 2

[0034] In this example, induction heating is used to improve the magnetic properties of sintered NdFeB magnets. The specific process steps are basically the same as in Example 1, the difference is that in step 4), the temperature of the magnet is raised to 780°C after induction heating Temperature insulation, insulation time is 30 minutes.

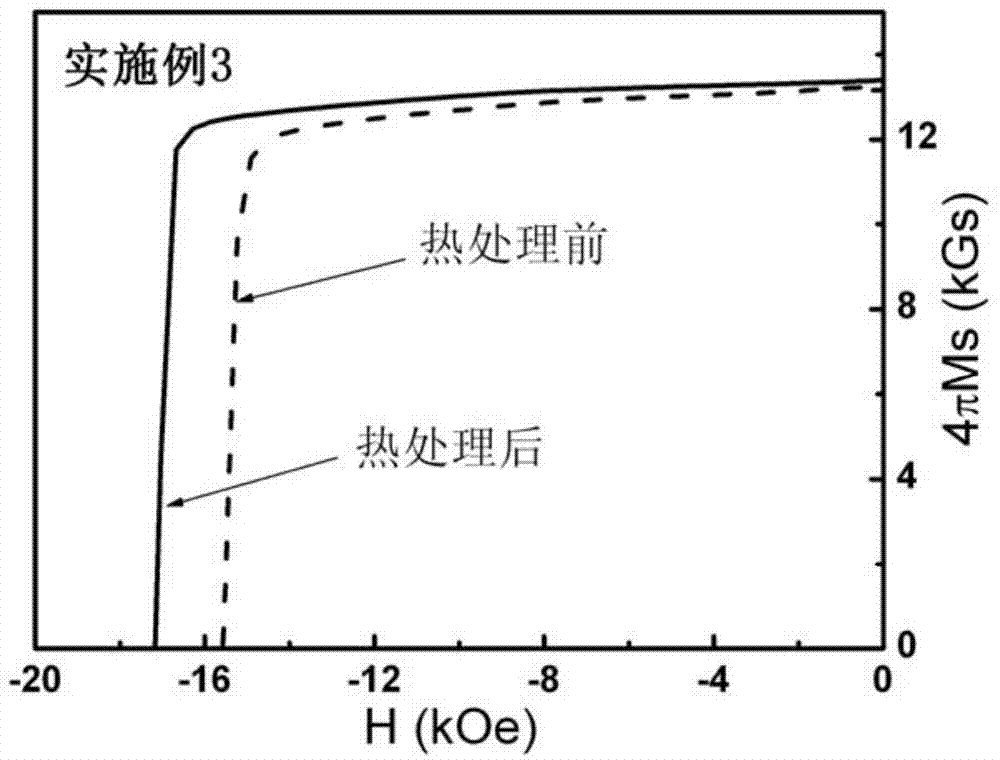

Embodiment 3

[0036] In this embodiment, induction heating is used to improve the magnetic properties of sintered NdFeB magnets. The specific process steps are basically the same as in Embodiment 1, the difference is that the furnace cavity of the vacuum induction furnace in step 3) is vacuum, and the air pressure is lower than 7.8×10 -3 Pa; in step 4), the temperature of the magnet is raised to 700°C after induction heating and then kept at this temperature for 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com