Indium seal method for tight connection between laser crystal and red copper heat sink

A technology of laser crystal and red copper, which is applied to lasers, laser parts, phonon exciters, etc., can solve the problems of large thermal resistance and difficulty in achieving efficient heat dissipation, and achieve the effects of increasing contact area, soft texture, and improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

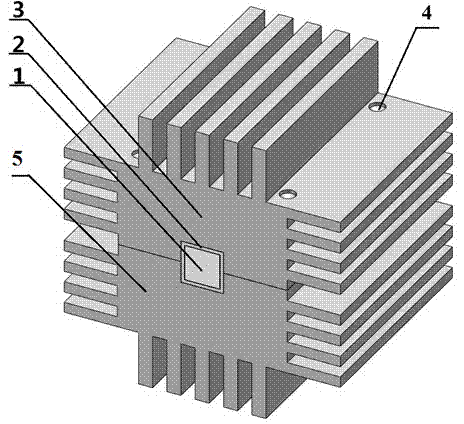

[0016] Specific implementation mode one: as figure 1 As shown, this embodiment provides a laser crystal heat sink based on the indium sealing welding process. The heat sink is mainly composed of a laser crystal 1, an indium foil 2, a copper heat sink and a screw 4 for fixing the copper heat sink.

[0017] In this embodiment, the copper heat sink is composed of an upper copper heat sink 3 and a lower copper heat sink 5, and the upper copper heat sink 3 has four through holes, and the lower copper heat sink 5 is provided with the upper copper heat sink 3. The positions of the upper through holes match the four threaded holes, and the upper copper heat sink 3 and the lower copper heat sink 5 are fastened and connected by four screws 4, and grooves are provided on the connection surface.

[0018] In this embodiment, the thickness of the indium foil is 0.5mm.

[0019] In this embodiment, the side of the laser crystal is wrapped with indium foil and put into the groove of the coppe...

specific Embodiment approach 2

[0023] Specific embodiment two: an indium sealing method for tightly connecting the laser crystal and the copper heat sink, which is realized by the following steps:

[0024] Step 1, cleaning off the oxide layer on the surface of the indium foil and the copper heat sink.

[0025] Step 2. Wrap the side of the laser crystal with indium foil and put it into the groove of the copper heat sink. The upper and lower copper heat sinks are fixed by screws.

[0026] Step 3. Put the connected and fixed red copper heat sink into the heating furnace, and the heating furnace is evacuated until the vacuum degree is about 0 torr.

[0027] Step 4: Heat the furnace to 160°C, and control the heating time for about 1 hour. Due to thermal inertia, the temperature will be about 170°C after 1 hour, and the indium foil will melt to weld the laser crystal and the copper heat sink.

[0028] Step 5. Turn off the heating furnace and take it out after the copper heat sink cools down.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com