Optical fiber coupling semiconductor laser device

A fiber coupling and semiconductor technology, applied in the laser field, can solve the problems of reducing the coupling efficiency of fiber-coupled semiconductor lasers and limiting the maximum optical power, etc., to achieve the effects of ensuring beam quality, increasing output power, and high transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

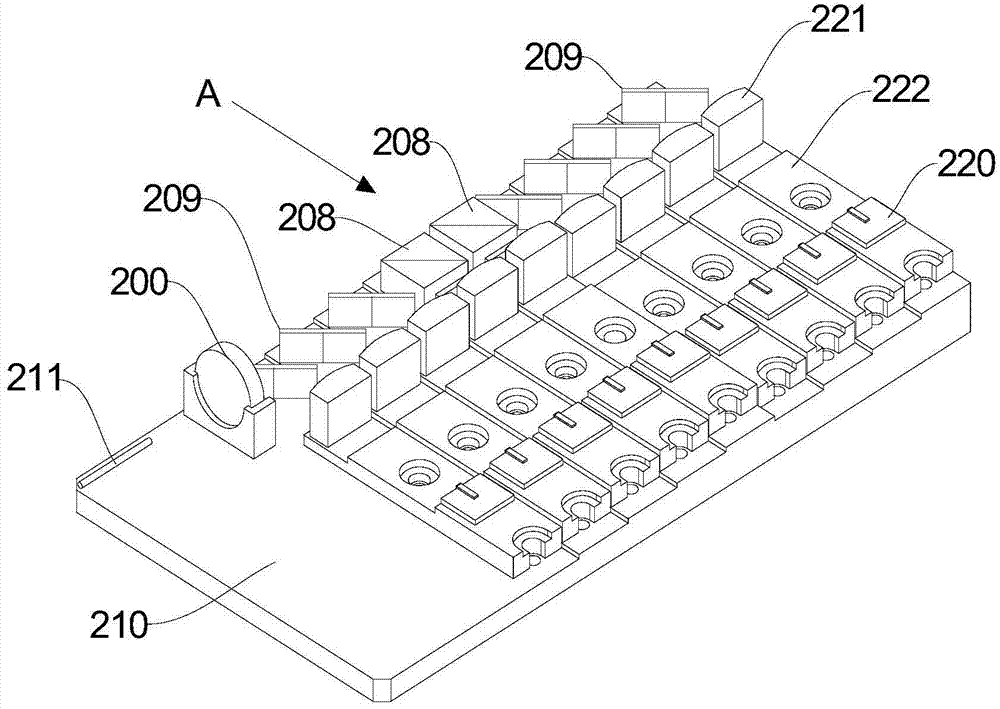

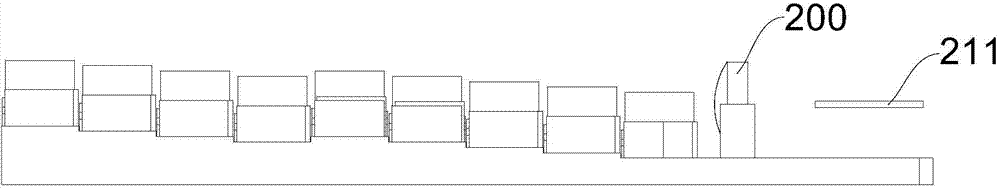

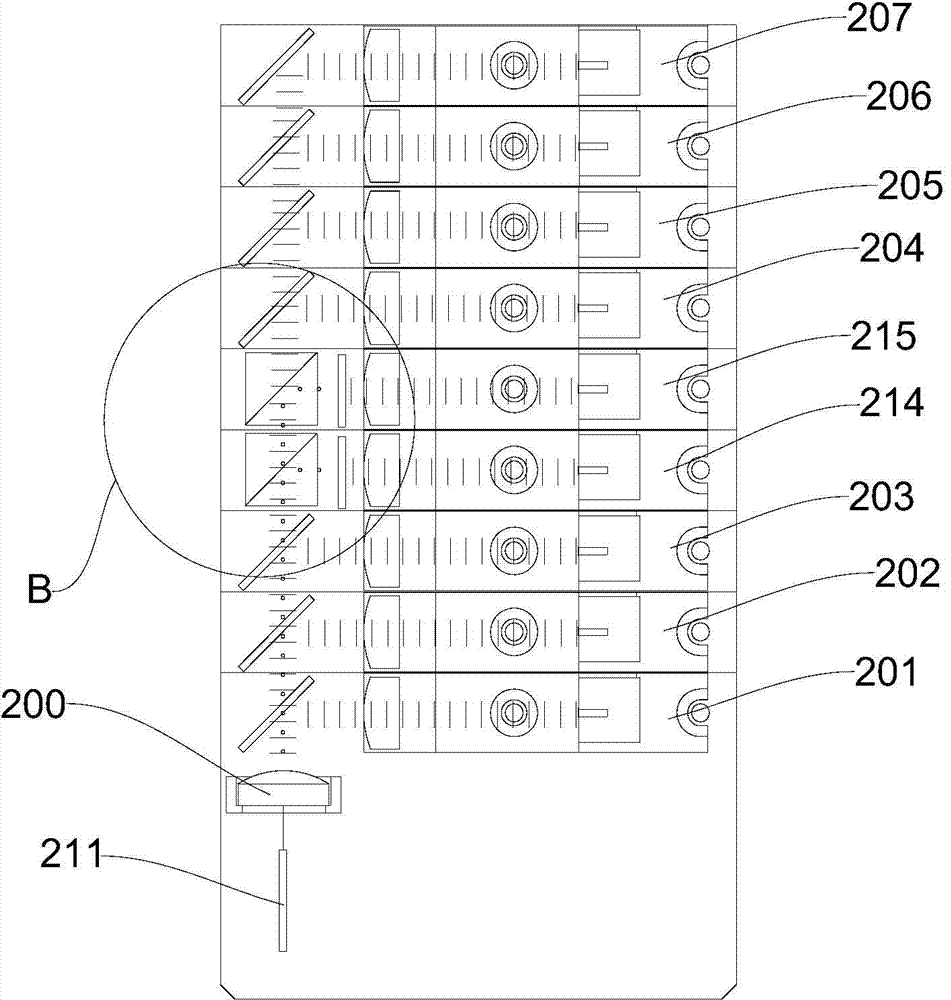

[0059] figure 1 is a schematic structural diagram of Embodiment 1 of the present invention, figure 2 Yes figure 2 A view in direction A, image 3 is a schematic diagram of the optical path of Embodiment 1 of the present invention, Figure 4 Yes Figure 4 The enlarged schematic view of the center B, Figure 5 It is a schematic view of the spatial arrangement of the light spots in front of the coupling mirror in Embodiment 1 of the present invention; Figure 1-5 As shown, Embodiment 1 of the present invention discloses a fiber-coupled semiconductor laser, which includes a coupling mirror 200 and a semiconductor laser module capable of outputting multiple beams of P light and at least one beam of S light.

[0060] The coupling mirror 200 is used to couple multiple beams of P light and at least one beam of S light finally output by the semiconductor laser module into one beam to form converged light; the number of beams of P light is greater than the number of beams of S ligh...

Embodiment 2

[0086] Image 6 It is a structural schematic diagram of Embodiment 2 of the present invention, Figure 7 Yes Figure 7 View from direction C in, Figure 8 It is a schematic diagram of the optical path of Embodiment 2 of the present invention, Figure 9 Yes Figure 9 The enlarged schematic view of the part at D in the center, Figure 10 It is a schematic view of the spatial arrangement of light spots in front of the coupling mirror in Embodiment 2 of the present invention. Embodiment 2 of the present invention discloses a fiber-coupled semiconductor laser, which includes a coupling mirror 300 and a semiconductor laser module capable of outputting multiple beams of P light and at least one beam of S light; the coupling mirror 300 is used to couple the semiconductor laser The module finally outputs multiple beams of P light and at least one beam of S light to be coupled into one beam to form a converged light; the number of beams of P light is greater than the number of beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com