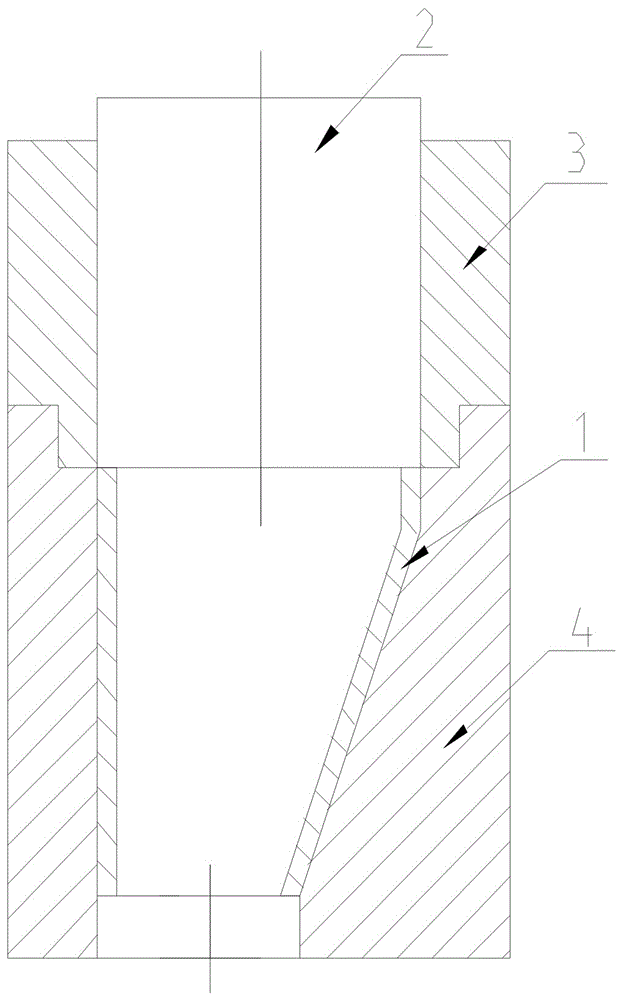

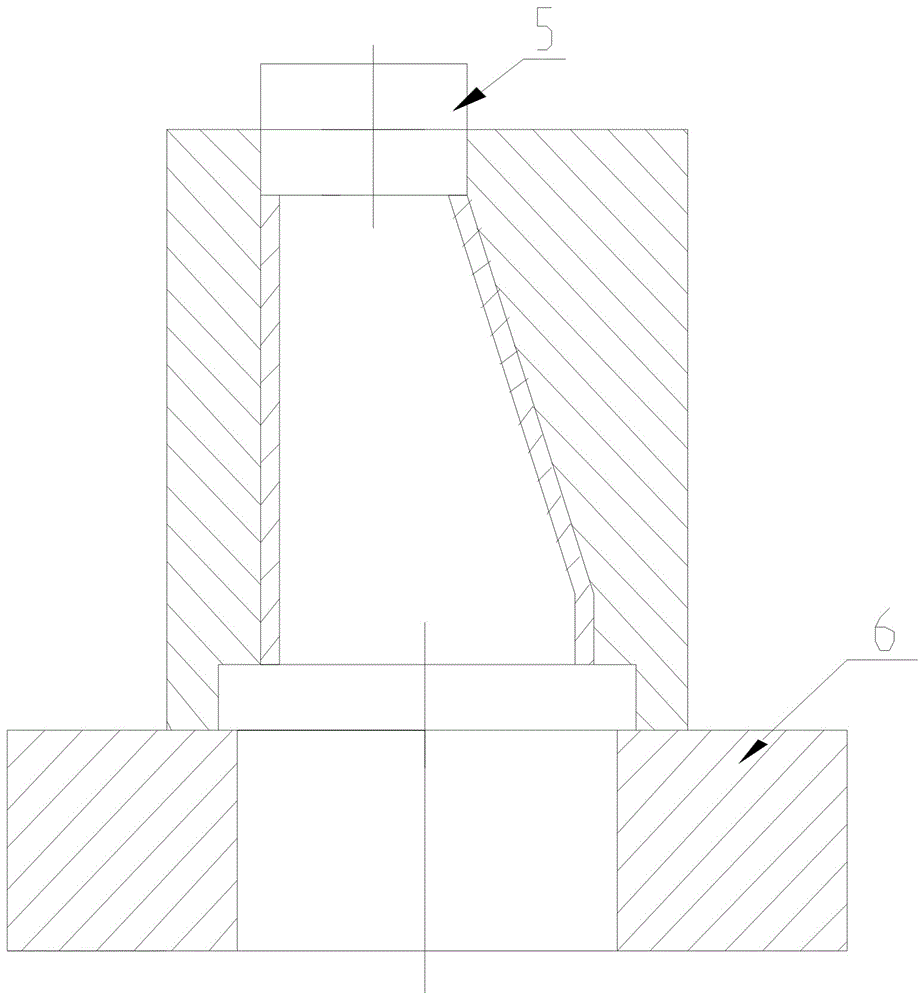

A kind of forming process method of titanium alloy eccentric reducing pipe

A technology of forming technology and variable diameter pipe, which is applied in the field of metal material processing technology and manufacturing, can solve the problems of shortening the cutting length of pipe materials, low raw material utilization rate, and low production efficiency, and achieves shortening the cutting length, related technologies The further improvement of the level promotes the effect of improving the utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The present invention has been applied to titanium alloy eccentric reducing tubes of Φ114.3 / Φ101.6 specifications. The weight of a single piece of blank has been reduced from 0.94KG to 0.8KG, and the material utilization rate has increased by 14.9%. The 50-60 minutes for each piece in the previous period was shortened to the current 5-6 minutes for each piece.

Embodiment 2

[0061] The present invention has been applied to titanium alloy eccentric reducing tubes of Φ101.6 / Φ88.9 specifications, the weight of a single piece of blank has been reduced from 0.62KG before to 0.49KG now, the material utilization rate has increased by 20.9%, and the forming time has decreased from before The 50-60 minutes for each piece in the previous period was shortened to the current 5-6 minutes for each piece.

Embodiment 3

[0063] The invention has been applied to titanium alloy eccentric reducing tubes of Φ88.9 / Φ73.0 specifications. The weight of a single piece of blank has been reduced from 0.5KG before to 0.39KG now, the material utilization rate has increased by 22%, and the forming time has been reduced from before. The 50-60 minutes for each piece in the previous period was shortened to the current 5-6 minutes for each piece.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com