Anaerobic packing low-temperature and high-dosage-rate irradiation sterilization method of gelatin

A technology of irradiation sterilization and high dose rate, applied in packaging sterilization and other directions, can solve the problems of loss of application value, fragile capsules, and decreased viscosity, and achieve the effects of good capsule strength, good swelling and remarkable effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

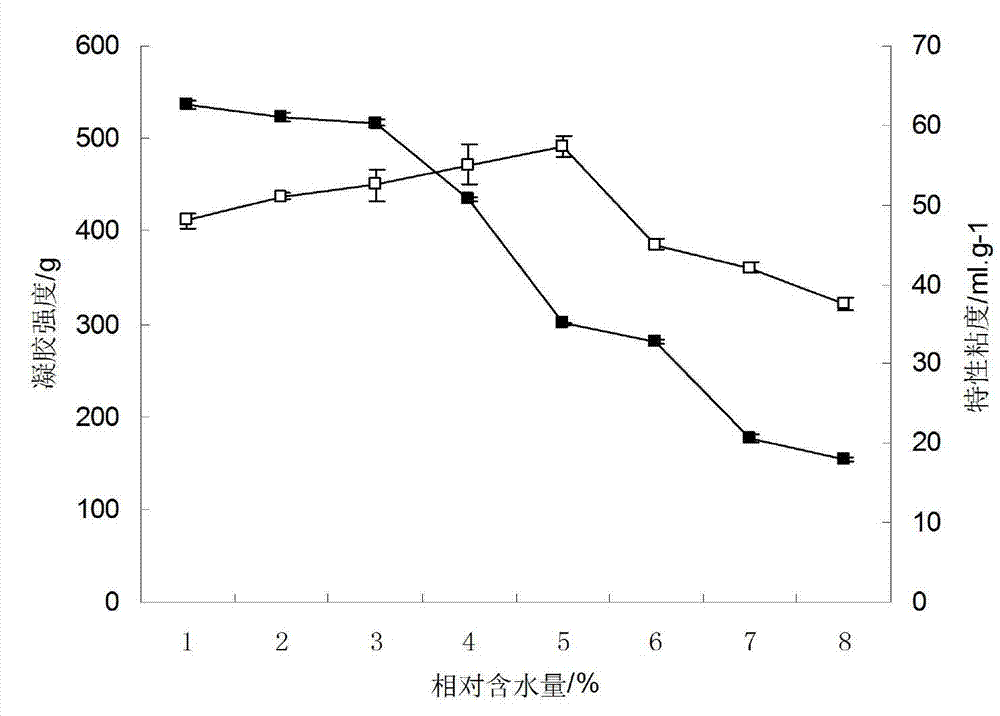

[0028] Embodiment 1 (moisture control):

[0029] The low-temperature high-dose-rate irradiation sterilization method for gelatin anaerobic packaging comprises the following steps:

[0030] 1) Place MgCl in the inner bottom of the vacuum desiccator 2 , NH 4 NO 3 、KNO 3 Place the gelatin on the dividing plate, after balancing for 48h, record the water content of the gelatin with a moisture meter to be 4.64% (mass) (sample of the present invention), 8.64% (mass) (sample of the present invention) ), 18.22% (mass) (the sample of the comparative example). Take gelatin and the mode that water is directly and rapidly mixed in different proportions to obtain water content of 33%, 50%, 66% and 80% (mass) of gelatin (a total of 5 parts of gelatin of comparative examples, control different moisture).

[0031] Another portion of gelatin was air-dried at 50° C. to constant weight to obtain a sample with a water content of 0% (mass) (the sample of the present invention).

[0032] 2) Ge...

Embodiment 2

[0039] Embodiment 2 (low temperature pretreatment):

[0040] The low-temperature high-dose-rate irradiation sterilization method for gelatin anaerobic packaging comprises the following steps:

[0041] 1) The gelatin was air-dried at 50° C. to obtain three samples with a water content of 10% (mass);

[0042] 2) adopt polyethylene material bag to the gelatin of step 1), vacuumize;

[0043] 3) The packaged gelatin in step 2) was pre-cooled for 6 hours at 0°C (the sample of the present invention), 10°C (the sample of the present invention) and normal temperature (25°C, the comparative example) respectively, and then packaged in a thermal box;

[0044] 4) The gelatin pre-cooled and packaged in step 3) is irradiated with cobalt-60 source rays at a dose rate of 200Gy / min, and the absorbed dose is 6kGy.

[0045] 5) Step 4) The irradiated gelatin is checked by electron spin resonance instrument whether it has been irradiated. The ESR peak of the irradiated gelatin is 2 independent si...

Embodiment 3

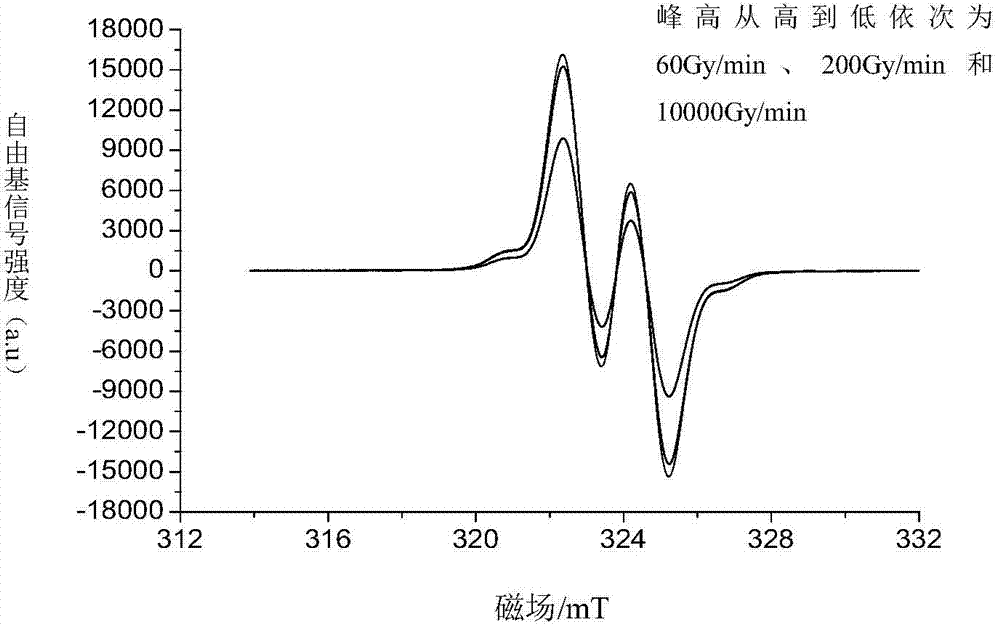

[0050] Embodiment 3 (high dose rate irradiation):

[0051] The low-temperature high-dose-rate irradiation sterilization method for gelatin anaerobic packaging comprises the following steps:

[0052] 1) The method of drying at low temperature (25°C) is used to control the relative water content of the gelatin to be irradiated to be 0%;

[0053] 2) adopt polyethylene material bag to the gelatin of step 1), vacuumize;

[0054] 3) The packaged gelatin in step 2) is pre-cooled at 0°C for 6 hours, and then packed in an insulated box.

[0055] 4) to step 3) the gelatin of precooling outer packaging adopts the cobalt-60 source ray (sample of the present invention) of dose rate 60 (comparative example), 200Gy / min respectively and 10000Gy / min dose rate electron beam irradiation (the present invention) Invented sample), the absorbed dose is 8kGy;

[0056] 5) The irradiated gelatin in step 4) is tested for free radical properties by electron spin resonance.

[0057] The gelatin irradi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com